XFlo - Position Transmitter

Today's modern process control systems need Position Transmitters and Limit Switches that deliver a high level of accurate position feedback. The infinite resolution potentiometer in the XFlo Position Transmitter senses the exact position of a valve coupled with a two-wire transmitter and sends a continuous 4-20mA signal to a remote indicating device. The XFlo Limit Switch Box houses two to four Micro-switches or Inductive Proximity Switches to indicate Open, Intermediate or Close position with redundant signal options. The Position Transmitter and Limit Switch Box can be combined in a XFlo PTLS2 box to provide accurate 4 – 20 mA feedback as well as two positions (Open, Intermediate or Close) via its two auxiliary switches. The Aluminium housing is compact and explosion proof, weather proof and dust proof.

...more

VFlo Segmented (V-Notch) Ball Valve

The VFlo – Segmented Ball Valve is designed to provide effective control for demanding applications. It is a rugged design segmented ball valve which overcomes the problems of harsh, particle entrained processes, and fibrous/unclean services. The VFlo also provides accurate, reliable control in a broad range of applications, such as Chemical, Power and Oil & Gas, Petro-Chemical & Pulp & Paper. The VFlo addresses and solves many long-standing challenges faced by traditional ball valves like: Piping forces that unevenly load the seal Low rangeability due to limited orifice characterization Unsatisfactory shutoff capabilities Metal Seal: Using the pressure drop across the valve, flex-lock sealing energises the seal to bubble tight shutoff in either flow direction. ANSI class IV is achieved with a metal seal. With an increased differential pressure, the sealing capacity is increased with flex-lock. With the pressure entering the cavity with the shaft downstream, the flexible seal deflects into the ball, and causes it to seal tighter against the ball. With pressure entering the cavity with the shaft upstream, the back-up ring locks the seal against the ball and causes it to seal tighter against the ball. Soft & Dual Seal: Using the pressure drop across the valve for soft sealing as well, the VFlo energises the seal to bubble tight shutoff in either flow direction. ANSI class VI is achieved with a soft seal and ANSI class IV with a dual seal. The Soft seal ring is standard for the VFlo and utilizes a 316 SS or Inconel Ring as a backup in conjunction with a Filled PTFE / PEEK seat. Such design provides for a quick and easy replacement in case of failure. The backup ring also provides shear action hence scraping any developments on the ball.

...more

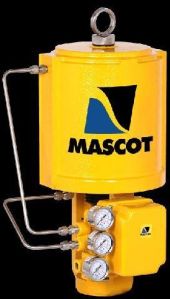

rotary actuator

High torque and pneumatic stiffness combine together in the MASCOT Spring cylinder rotary actuator. These characteristics are designed into a lightweight, rugged and compact assembly, making the MASCOT rotary actuator the first choice for quarter turn applications. The MASCOT rotary actuator is created for operating the DiskFlo high performance butterfly valve, VFlo Segmented Ball Valve, EFlo Eccentric Plug Valve, QuickFlo Full Bore Ball Valve or other applications requiring precision in rotary motion. The MASCOT Rotary uses a rocking piston assembly for direct conversion of linear motion to rotary motion. The rocking piston assembly along with a splined shaft and lever eliminates any lost motion due to backlash. It is a compact and light weight actuator which has many interchangeable parts with the Linear Actuator hence reducing the spare part inventory and maintenance costs. Adjustable stroke stops prevent excessive rotation and reduce excessive torque on shaft. They also act as mechanical limit stops to mechanically limit the control valve’s travel for safety considerations

...more

Miniature valves

MegaFlo Noise Attenuation Trim

The MASCOT MegaFlo trim effectively reduces the gaseous noise in control valves. MegaFlo design is a result of extensive research and engineering study. Various principles have been incorporated into the trim design allowing it to be used in varied applications like chemical/petroleum plants, refineries, power plants, process industries, nuclear industries and wherever a highly effective noise reduction valve is required. Some of the built in design features are: Staged Pressure Reduction through a series of carefully designed drilled hole cages called “Stages”. Velocity Control. Turbulence Control. Acoustic Impedance. Generous Plug to Inner Cage (Stage) clearance which avoids galling and seizing.

...more

Linear Actuator

MASCOT spring cylinder linear actuator is a powerful, high-performance pneumatic actuator, which provides positive throttling or on-off operation to pneumatic control valves. Uniquely designed compact sized cylinders actuators accept supply pressures up to 150 psi, making very high thrusts available in a relatively compact unit. The basic 4 sizes cater to almost 85% of a plant’s requirement hence reducing the inventory & cost of maintenance spares. The MASCOT spring cylinder linear actuator is fully field reversible for air to open or air to close action without additional parts; a spring provides reliable fail-safe operation. Air is supplied to both the sides of the piston by the positioner providing very stiff and precise movement along with very high frequency response

...more

HiFlo Positioner

MASCOT HiFlo Positioners are Pneumatic and Electro-Pneumatic Positioners primarily used by MASCOT Control Valves equipped with Linear or Rotary Actuators. A pneumatic module for 0.2-1.0 bar air control signals, or an electro-pneumatic module for 4 to 20mA electrical control signals is offered with MASCOT HiFlo valve positioner. Valve positioners are single or double-acting, force-balanced instruments that provide fast, sensitive and accurate positioning of MASCOT Spring Cylinder Actuators as well as diaphragm actuators. These rugged positioners being compact, field reversible, are designed for high performance. They offer separate Zero and Span adjustment for ease of calibration. The MASCOT HiFlo Valve positioner is a force-balanced instrument. Positioning is based on a balance of two forces; one proportional to the instrument signal and the other proportional to the stem position. A downward force is activated as the signal pressure acts upon the diaphragms in the instrument signal capsule, through the follower arm and cam, the motion of the actuator stem is transmitted to the top end of the feedback spring resulting in the varying of tension in feedback spring as stem position changes. The system will be in equilibrium and stem will be in the position called for by the instrument signal when these opposing forces balance exactly. The balance will move up or down and by means of the spool valve, will change the output pressures and flow rate if these opposing forces are not in balance. This will lead to the piston to moving until the tension on the feedback spring opposes exactly the instrument signal pressure.

...more

GFlo Globe Control Valve

Superior performance in liquids and gaseous services is the hallmark of the GFlo Globe Control Valve. Easy, quick and economical maintenance makes the GFlo Globe Control Valve more user friendly. The spring cylinder actuated GFlo imparts stiffness and maintains very high precision in positioning, strong response, repeatability and controlled high speed movement are the characteristics absent in diaphragm operated control valves. GFlo has the thrust capability to shutoff against higher fluid pressures as it can handle up to 150 Psi / 10.30 Bar air supply. Valve closure is totally dependent on springs in most diaphragm actuators. The unique design of GFlo enables it to combine the spring force, fluid pressure and supply air pressure to achieve an extremely tight shutoff. A self-aligning seat ring adds to and further improves the shutoff capability. Galling at cage is the culprit in many common maintenance issues with globe valves because of the close metal-to-metal contact between plug & cage. The GFlo has two top heavy duty stem guides. Contact between the plug and seat retainer is completely avoided in GFlo. Easy and quick maintenance is permitted due to clamped-in seat and top entry trim. Salient Features: Reliable High-thrust Cylinder Actuator. Accurate Positioning. High Repeatability. Double Stem Guiding does not come in contact with operating fluid. Sufficient Clearance between plug head and seat retainer to avoid galling. Self-Aligning seat ring. Shutoff assisted by fluid pressure, cylinder spring and air pressure. Corrosion resistant construction. High Thrust cylinder overcomes high pressures to provide exceptional tight shutoff. Anti-Cavitation and Noise Attenuation trim options. Heavy-Duty plug stem. Excellent Interchangeability between sizes and other MASCOT products. Valve design minimizes requirements for stocking spare parts. Stiff, Heavy-Duty parts provide extended life.

...more

FlushFlo Flush Bottom Valve

The MASCOT FlushFlo is used at the bottom of large tanks / digesters and driers to discharge the processed fluid to a further process. The inlet and outlet flange is completely customizable to the customer’s tank and it is available in a varying angles of 90°, 120° & 135°. The Plug can be Quick Opening type or with a Linear, Equal Percentage Characteristic. The Self Aligning seat ring ensures tight shutoff without Lapping even after prolonged use. The plug can be equipped with an RTD for temperature measurement and control

...more

EFlo Eccentric Plug Valve

The EFlo offers a high performance rotary globe valve which provides precision control over extended life span through enhanced safety. The MASCOT EFlo is a high performance, safety focused, economical, yet feature rich, Eccentric Rotary Plug control valve for applications demanding higher rangeability, precise control and higher flow capacity. The EFlo valve offers rangeability up to 160:1 - compared to 50:1 for typical globe control valves and 20:1 for most butterfly valves. A heavy-duty, non-crossover shaft is out of the valve’s flow path. This superior design allows higher flow capacity for a given valve size. It also eliminates shaft damage from erosive process fluids. Many competitor designs use a straight-thru shaft which presents an obstruction to the flow, limiting capacity and presenting a target for erosion. The EFlo offers positive, anti-blowout protection by means of a separate bonnet and integral shaft collar, as a standard option, emphasizing its status as the safest Eccentric Rotary Plug valve on the market. The end-post shaft is designed so there is no possibility for it to be lost downstream. The end-post is rugged, precision machined, perfectly aligned, and positively retained so movement is smooth and precise. The oversized shaft provides improved reliability and valve life by eliminating shaft failures and reducing bearing wear. Salient Features: Non-Crossover Shaft: Pocket-less flow-path tolerates slurries, even up to 3% paper stock. Unobstructed flow when fully open. Up to 70% greater capacity than other ERP control valves. Not eroded by process-born particles. Eccentric Rotary Plug: Plug does not rub seat ring. Less wear, less friction, more precision. Stable throttling, low dynamic torque. Stable throttling in either flow direction. Inherently Linear characteristic. Flow direction assists movement to safety position on air-failure. Robust, rigid seat and plug give increased durability. Tight Shut-off, Class IV (Metal Seat), Class VI (Soft Seat), even after prolonged usage. Separate Bonnet and Integral Shaft Collar: A positive anti-blowout as a standard feature, in full compliance with ASME B16.34 Section 6.5.1, ensures that the shaft cannot blow out, even if the actuator is removed. Trim Choices & Plug Design: Hardened plug gives high performance and long service life. Flow Capacity can be closely matched to the process application. Full Area, 75 / 70%, 40% seats are economical to replace when optimizing flow capacity or changing service conditions.

...more

DiskFlo Butterfly Valve

The high-performance DiskFlo Butterfly Valve is used to achieve bi-directional bubble-tight shutoff while maintaining low breakout torque at high and low pressure drops. The high-performance DiskFlo Butterfly Valve uses pressure assisted Jam-lever toggle seating concepts. By utilizing the pressure drop across the valve to aid the seating process, Jam-lever toggle seating assures low breakout torque. The need for strong actuator seating force is reduced since much of the force is supplied by the fluid pressure. To achieve especially high-performance throttling, even in large pressure drops close to the seat, it is combined with a MASCOT high thrust cylinder actuator and a double eccentric cammed disc. Soft Seat: To help energize the soft seat to bubble-tight shutoff in either flow direction, including alternating flow applications, Jam-Lever Toggle seating concepts utilize the pressure drop across the valve. Jam-lever Toggle soft seats achieve ANSI Class VI shutoff. Metal Seat: For applications involving temperatures higher than those permitted by the Jam-lever Toggle soft seat, metal seats are used. A highly flexible lip, which assures full circle contact between the seat and disc when the valve is closed, is incorporated in the design. The lip flexibility permits breakout torque for the metal seat is the same or less than soft seat breakout torque. ANSI class IV shutoff is achieved through DiskFlo metal seats. Dual Seat: DiskFlo dual seats incorporate both the Jam-lever Toggle soft seat and the flexible lip metal seat for added protection in unclean fluids or demanding applications. It also makes the DiskFlo a Firesafe Butterfly Valve. DiskFlo Double Eccentric Cammed Disc To lift it out of the seat immediately upon actuation, a double offset has been designed into the disc. This avoids wear on the seat and disc, reducing leakage and parts replacement. The throttling also improves as the friction is eliminated. Flow Direction Jam-lever Toggle seating allows DiskFlo to flow either shaft downstream or shaft upstream, depending on service conditions. With the shaft downstream the flow tends to open the valve. With the shaft upstream the flow tends to close the valve. Flow Characteristics The inherent flow characteristic of the DiskFlo valve is a modified parabolic. Other characteristic curves are achievable by means of a MASCOT HiFlo Positioner or a SMART positioner.

...more

DeFlo VSD Variable Spray

The DeFlo VSD integrates the precision and simplicity of a Control Valve into a Desuperheater to attain maximum turn-down, responsiveness and accurate control. For the maximum efficiency the DeFlo VSD atomizes the cooling fluid at the vena contracta just downstream of the throttling point right at the injection point. The special design of the spray retainer ensures a hollow swirling cone pattern of the atomized fluid. The total cooling water differential pressure is available at the throttling point hence optimizing the atomizing effect even further. The integrated MASCOT DeFlo VSD: No Additional cooling water control valve required. Class V shut-off available. Probe installation which does not influence the piping geometry or velocity of the gas. Lower maintenance cost: No additional valve to service, integrated lightweight & compact high performance actuator.

...more

DeFlo SCV Steam Conditioning Valve

This combined type Pressure Reducing cum Desuperheating control valve is a compact yet effective and carefully designed device. The MASCOT DeFlo SCV eliminates all common issues faced by combined type steam conditioning valves. The SCV is the most efficient way of steam conditioning where the water is injected in a highly turbulent area to ensure most efficient water to steam mixing. The DeFlo SCV are available in Standard, Angle and Expanded outlet configuration. No special expertize is required to operate or maintain the MASCOT DeFlo SCV as it utilizes most spares of a Standard GFlo Globe Control valve with an addition of a Thermal Desuperheating Sleeve at its outlet. This spray method protects the valve belly from pitting and thermal shocks/stresses unlike most competitive designs. This also reduces the SCV maintenance costs as the Valve and Trim life is greatly enhanced. With an extended knowledge of Control Valves and Desuperheating units MASCOT is one of the only two specialists in the world who are in the field of Pressure Reducing and Desuperheating.

...more

CavFlo Cavitation Control Trim

The MASCOT CavFlo trim effectively minimizes cavitation damage to control valve components by controlling the location of vapour bubble implosion in an area away from metal parts. Problem: Cavitation Damage Cavitation is a two-stage process: First, as fluid velocity increases through the restriction at the vena contracta, the pressure of the flowing liquid drops below the vapour pressure causing vapour bubbles to form. Second, as the flow enters the enlarging passageway downstream of the vena contracta, the velocity decreases. The resultant pressure recovery raises the fluid pressure back above the vapour pressure, causing the vapour bubbles to collapse or implode. The implosion of the bubbles on metal surfaces stresses and eventually tears away particles of the metal. Throttling in most globe valves occurs at the restriction created by the clearance between the valve plug and seat ring; therefore, both can be severely damaged by cavitation. In addition, imploding vapour bubbles near the valve body and adjacent piping can also cause damage. The Solution: CavFlo Trim: MASCOT CavFlo trim utilizes a number of small, diametrical flow holes through the walls of the seat retainer. As the valve plug lifts off the seat, increasing pairs of holes are opened. Each hole admits a jet of cavitating liquid, which impinges in the center of the retainer upon the jet of liquid admitted through the opposing hole. The impinging fluid jets form a fluid cushion and an area of pressure recovery that cause the collapse of the vapour bubbles in the fluid stream away from metal parts. Stepped holes are used to ensure orifice type flow rather than tube type flow through the retainer; thus, the vena contracta is established externally rather than inside the retainer itself. The turbulence of the impinging flow promotes the collapse of vapour bubbles at the center of the seat retainer, minimizing damage to valve trim. The valve plug fits the retainer closely, controlling the fluid flow through the holes. Therefore, the fluid must be fairly clean to avoid sticking and galling problems between plug and retainer. Multistage CavFlo: The CavFlo multistage cartridge may appear similar to other competitive designs because of its drilled holes and close-fitting cylinders but here the similarity ends. Rather than acting as a flow restriction, the drilled holes in the CavFlo multistage cartridge are used as expansion areas for the fluid as it enters from restrictive channels machined in the outside of all interior cylinders. This prevents the fluid recovery from occurring adjacent to a critical trim surface. Successive intersections of the restrictive channels result in additional pressure losses while expansion holes connected to the channels create a series of expansions and contractions that result in a series of pressure drops. This staged pressure drop eliminates cavitation in most applications and minimizes the energy of cavitation that may still occur in others. No Clogging Design: Anti-cavitation valves are typically constructed with small flow passages that can become plugged by dirt or other debris in the fluid stream. Such devices usually direct the flow initially to the throttling plug before passing it through the restrictive device. This results in sticking and galling as dirt and other material become trapped between the sliding plug and the inside surface of the anti-cavitation device. On the other hand, CavFlo is designed with two important protective features to minimize such plugging problems: First, flow is first brought through the cartridge; contaminants too large to pass through the small outer channels are trapped at the outer-most stage of the cartridge preventing debris from traveling through the device to the throttling plug. Second, because the inner channels progressively become larger, small particles (which pass through the first set of channels) are easily passed through the rest of the cartridge. In the unlikely event that the cartridge does become plugged, it can be easily disassembled and cleaned as the cartridges are never welded together.

...more

bore ball valve

Segmented Ball Valve is designed to provide effective control for demanding applications. It is a rugged design segmented ball valve which overcomes the problems of harsh, particle entrained processes, and fibrousunclean services. The VFlo also provides accurate, reliable control in a broad range of applications, such as Chemical, Power and Oil & Gas, Petro-Chemical & Pulp & Paper.

...more

Back pressure regulators

Air Regulators

Control Valve

Body Type:2 way, 3 way, Angle & Jacketed Body Materials:All Castable Alloys materials & From Bar Stock up to 2.0" End Connections:Flanged ( Integaral & Separable ), Screwed, Butt and Socket weld Bonnet:Standard, Extended, Cryogenic & Bellow Sealed Guiding:Heavy duty double top stem Gland Packing:PTFE, Braided PTFE, Grafoil, Fugitive Emission, Vaccum Gaskets:PTFE, Spiral Grafoil, Glass filled S S Seat Ring:Clamped - in self aligned Plug:Large seat contact area large diameter stem is an integral part Characteristics:Equal Percentage, Linear and Quick-open (On - Off) Range-ability:50 : 1 Special Trims:CavFlo, MegaFlo, dB Plates, VCFlo Actuator:Spring Cylinder Linear, Fully Field Reversible Air pressure:2.0 to 10.0 Bar Shut off class:With Metal seat - ANSI IV or V and replaceable Soft seat - ANSI VI

...more

DeFlo Mini Mechanical Spray

The DeFlo Mini is one of the most basic type of Desuperheater which utilizes a MASCOT GFlo Globe Control valve as its cooling water control valve. It consists of fixed jets arranged to face the steam flow direction through the periphery of the Desuperheater sleeve. It works well in stable conditions where the steam flow turn-down is a maximum of 4:1. The Stainless Steel sleeve acts as a thermal liner and is of the size of the steam pipe ID hence eliminating localized velocities created by many competitor designs. For low turndown applications or in oversized pipes a venturi sleeve can be provided which creates local turbulence and velocity for effective mixing of the water with the steam.

...more

Control Valves

Globe Control Valves

desuperheaters

Butterfly Valve

Steam Traps

Be first to Rate

Rate ThisOpening Hours