Toilet Soap Plant

Capacity : 100-120 Kg per Hour

Sugarcane Juice Machine

Crushing Capacity : 100 Kg per Hour

Power : 0.5 HP

Voltage : 220V - 1 Phase - 50 Hz

Weight : 41 Kg

...more

Soap Vacuum Plodder Machine

Brand Name : Micmac

Soap Sigma Mixer Machine

Brand Name : Micmac

Soap Roll Mill Machine

Brand Name : Micmac

Soap Paddle Mixer Machine

Brand Name : Micmac

Soap Noodle Plodder Machine

Brand Name : Micmac

Soap Conveyor Machine

Brand Name : Micmac

ROTARY COLD OIL PRESS

we offer rotary cold oil press. rotary cold press is suitable to expel oil from oil seeds like white and black sesame, simsim, coconut, almond, peanut and other soft oil seed. the extraction of oil is less compared to expellers but the advantage is that the oil has better aroma and fragrance, better nutritional value suitable for application of carrier oil for massage oil , herbal preparation and better therapeutic value.

...more

PULVERIZER

We offer pulverizer - maize mill - cereal grinding machine.this pulverizer are used to as maize mill it can also be used as spice grinding machine , masala grinding machine, salt grinding machine, sugar grinding machine, coffee grinding machine, fresh fruits, vegetables, tobacco, soopari, herbs grinding machine , oil cake grinding machine, dried fish grinding machine, bones grinding machine , cardboard, leather cork, dyes, pigments, roots of trees, bark of trees grinding machine , etc. Etc. The pulverizer maize mill is very simple in operation. The material to be ground is fed in hopper at the top pulverizer. The sliding gate is adjusted to supply material in the grinding chamber. The flow rate is adjusted such that ampere rating shown by the motor is optimum. The material is ground by the striking of beaters rotating at high speed with the material inside the chamber. The centrifugal force of the blades is so high that the material is broken to pieces when it collides with outer replaceable lining. The grinding chamber has screen at the bottom of different size to suit the mesh of material to be ground. When particle size has reduced below the screen size the ground material under the pressure of air sucked is collected in the collected in the dust bag . The material comes out of sieves and hence sieving is avoided. The pulverizer maize mill is very simple in operation. The sieves are easily replaced after removing the top cover of the grinding chamber. The blades are easily replaced. The machine can be cleaned very easily. The pulverizer maize mill is supplied with two set of blades and two sets of three different size of sieves. The machine runs on 5 hp motor. The machine is supplied with electrical and motor. The pulverizer maize mill working on diesel engine can also be supplied.

...more

Popcorn Making Machine

We offer popcorn making machine. Salient features v strong and attractive cabinet of powder coated square pipes. V frames of aluminum section with glass windows. V chromium plated cooking kettle. V stainless steel bottom of the cabinet. V control panel with 5 switches. V automatic kettle lid lifting device. V locking facility for cabinet.

...more

Plodding Machine

380,000 Per UNIT

1 UNIT (MOQ)

Phase : 3 - PHASE

Brand Name : MICMAC

Capacity : 125 - 150 KG/HR

Condition : New

...more

Oil Soap Reactor

Brand Name : Micmac

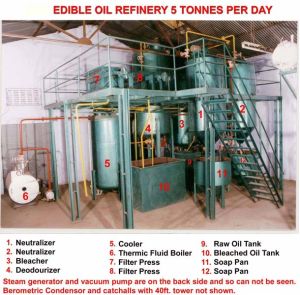

Edible Oil Refinery Plant

there are three basic processes in the edible oil refinery. First process is neutralizing the oil in the neutralizer to remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated upto about 60°C by thermic fluid coils and oil is stirred by stirrer. Then soap stock formed due to chemical reaction is allowed to settle at the bottom of the neutralizer from where it is taken out into soap pan

...more

Cooking Refinery Oil

We offer cooking refinery oil . For refining the oil, there are three basic processes in the edible oil refinery. First process is neutralizing the oil in the neutralizer to remove the free fatty acids (ffa) by adding caustic soda. Oil is heated upto about 60°c by thermic fluid coils and oil is stirred by stirrer. Then soap stock formed due to chemical reaction is allowed to settle at the bottom of the neutralizer from where it is taken out into soap pan. Neutralized oil is drawn into the second vessel called bleacher where colour of oil is removed by bleaching process with aid of chemicals such as carbon black and bleaching earth. Oil is generally heated upto 110°c by thermic fluid coils. Stirring is also continued. Bleaching process is done under vacuum.

...more

Cooking Oil Mill Machinery

We offer cooking oil mill machinery. Salient features of cooking oil mill machinery 1.machinery is suitable for crushing all types of oilseeds whether edible for getting cooking oil or non edible. 2.filtration of oil is better than bigger oil mill giving transparent pure natural & "at a stretch convincing" appearance to the oil. 3.decorticator has special provision for shelling groundnut for seed purpose without breakage. 4.yield of oil is as high as big mills because of highly scientific worm sequence inside the chamber cage. 5.maintenance expenses are negligible. Diesel consumption in engine is only 1.25 litre per hour. 6.technology is so simple that person can be trained only in 3 days to operate the mill. 7.video cassette is provided with every export mill to explain operation, maintenance, names of components, dismantling, assembling etc.

...more

Cooking Oil Making Machine

Machinery is suitable for crushing all types of oilseeds whether edible for getting cooking oil or non edible. Filtration of oil is better than bigger oil mill giving transparent pure natural & "at a stretch convincing" appearance to the oil, Decorticator has special provision for shelling groundnut for seed purpose without breakage. Yield of oil is as high as big mills because of highly scientific worm sequence inside the chamber cage. Technology is so simple that person can be trained only in 3 days to operate the mill.

...more

Centreless Grinder

We offer centreless grinder.micro machines presents you precision, accuracy, quality, durability, rigidity, reliability, productivity, flexibility & economy in centreless grinding technology. The grinders are designed to satisfy ever increasing demands of modern industry. With plunge cut and through feed you can grind a wide range of materials like hardened and unhardened steel, cast iron, stainless steel, brass, aluminum, etc. With suitable grinding wheels. Grinding of cylinders, long bars, steeped cylinders, tapered parts, profiled jobs etc. Can be ground. Grinder bed is on piece seasoned graded cast iron. The place on which slides are mounted is made extremely rigid by providing ribs that form a grid structure. It minimizes vibrations. Grinding wheel head is fixed. The grinding wheel spindle is made of alloy steel. The spindle is case hardened to improve the wear resistance and toughness of the spindle. The bearings are either taper roller bearings or bush type. Spindle runs in an oil filled chamber. The drive to this spindle is by v-belts.

...more

Detergents Powder

Be first to Rate

Rate ThisOpening Hours