Stud Type Welding Machine

Modern Machine Tools 120 Amps. Machine is best suited for small repair and maintenance jobs, where portability is of prime consideration. This machine type is best utilised in intermittent operations.

...more

Spot Welding Machine

"Modern Machine Tools" pedal operated rocker arm type spot welding machine are offered in 6,8,10,15,20 and 25 KVA models each with three standard throat depths to cover practically all applications. All machines are made of steel fabricated rigid structures to eliminate the minutest spot deflections TRANSFORMER: Low leakage (High Linkage) design, proper cooling and insulation including winding impregnation to enhance reliability and service life. CURRENT CONTROL Current seting from min, to max. value can be done by a 6 position, off loap tap switch. TIME CONTROL Solid state Electronic timer to control weld time from 5 to 50 cycles and 1 to 10 seconds to achieve accurate and repeatable spots. WELD PRESSURE Adjustable max. pressure levels are derived from a heavy-duty comression spring mounted on a pressure rod with caliberated nut. Here a special arrangement in the machine minimises operator fatigue and ensures simple seting. COOLING Electrodes, holders and arms are provided with water cooling arrangement with hose connections. (Water supply to be attanged by the user.) ELECTRODES One Pair of Morse Taper 2 straight electrodes made from hardened copper-alloy is supplied with the equipment. Other types or spare electrodes can be supplied on specific orders.

...more

Slotting Machine

Our Slotting Machine is being prepared with Genuine Components with its Accurate Size : as well as with latest technology & all the components are being inspected at Every Stage of Production by our Qualified staff to Maintain Quality for every & we want to achieve satisfaction through our Quality Products. Also we look forward to Enhance Relationship with our Customers as well as attract new Business Relationship.

...more

Regulator Type Welding Machine

Useful for fast production, filling jobs, reclamation of worn-out machine parts, Arc cutting jobs and many types of truly heavy duty applications. Tested under strict quality control measures to give trouble free services for long period.

...more

Radial Drill Machine

Our Drill are well known machines, which have a sturdy built and is designed for both production and Toolroom jobs. The machine cover various range of operations like Drilling, Reaming, Tapping, Lapping, Boring & Counter Boring & Counter Boring in cast iron, steel and other materials.

...more

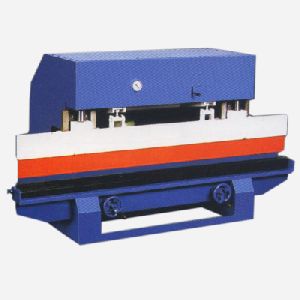

press break machine

Press Brake Machines are designed taking in to consideration all severe service conditions of sheet metal shop. The machine are heavy duty robust in design and acclaimed recognition in requiring high accuracy productivity & efficiency. Frame Construction: Frame in made of steel fabricated construction of interlocked robust design. Machines are constructed with safeguards against undesired deflections and breakage. The frame distributes the stresses, supporting the bed directly on the frame. The double support shoe of frame gap provides extremely high rigidity, alignment, accuracy and keeps frame structure at right angles to the bed. Ram & Bed: Ram and bed are straight and parallel of both the working surface under the rated load. The bed is accurately machined and upper surface is grinded to keep the die in correct alignment. The ram is guided and supported throughout the stroke by accurately machined guide ways. Lubrication System: The lubrication system on a machine is an assurance for its trouble free running. The bearing parts are linked with high density polythene pipe – line spread at every point where lubrication is required. Clutch and Brake: Press brake are provided with high-torque low-inertia friction clutch, synchronized with heavy duty. The powerful disc type clutch is easily accessible, simple to adjust and picks the load from standing start and it frequent start & stop. The brake is interlocked with clutch to stop the ram immediately at any point of motion. When the clutch is released. Clutch operating levers are designed in such a way that minimum engaging force is required at the pedal. Drive System: Power is transmitted to the ram through two individual gear drives for uniform load distribution throughout the length. This also reduces the torsion stresses on the eccentric shaft. Electric motor used is of sufficient H.P. which reduces slowdown of flywheel and increases energy available per stroke. The gear and pinion are made out of carbon steel. Ram Adjustment Mechanism: Motorized ram adjustment making it very easy to adjust the shut height to a desired value. The clutch offered easy operation in disconnecting either of Right or left screws in order to set the ram in correct position. This mechanism facilitates quick bending angle adjustment. Angular ram adjustment is made simple by incorporating a spring loaded dog clutch.

...more

Power Chuck

Open centre wedge hook chucks with thru hole are ideal for high speed chucking, bar chucking and universal machining. These chucks come fitted with back plate ready to mount on the machine.. SPECIAL FEATURES:- High Speed - Constant accuracy & high endurance - Strong Gripping - Available in 2, 3 & 4 Jaw configurations

...more

Metal Cutting Bandsaw Machine

Vice is clamp manually, Saw Arm is moved down upto job then as per gravity / cutting pressure blade cutts the job, After cutting operation completes the machine automatically stops in lower position.

...more

Mechanical Under Crank shearing Machine

Under Crank Shearing Machine is suited for cutting to size general purpose unalloyed steel. Structural steel sheets up to 4mm thickness with high productivity. Each machine, designed to the most accurate of efficiency, offers outstanding operational performance dimensional accuracy telling on high output and dependability. Frame Construction:Guillotine shearing fabricated from Is-226 Grade. Rolled steel plates. Table cutting Beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load supports. Thus the accuracy of the machine is never disturbed. BED: Super strong bed of closed box type construction. Stress relieved in a furnace. Forms a rigid backbone for the shear and a solid backing for the lower knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed are also provided for machined pad across the bed for convenient setting of front gauge brackets at any desired spacing. Depressions in the top of the bed provide ample clearance for fingers in handling sheets narrower than the bed. Upper Beam: Ram is also of solid steel plate, carrying the upper Knife. Their minimum weights ensure lesser load on the bearings. The upper beam moves in flat heat treated steel guide plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife. Hold-Down Mechanism: Solid clamping by powerful spring loaded hold down is one of the reasons for accuracy in our shears. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of variations in thickness. Hold down pressure is easily adjustable for clamping soft material. Different thickness of material can be cut without further adjustment with consistently accurate and burr free results. Rolling Key Clutch: Made of alloy steel for positive engagement and continuous operation having three key ways. Single rolling key system rolling key system is incorporated in the machine ensuring easy and efficient working of the machine. Shear Knives: Knives are manufactured strictly as per standard material of HCHCr/OHNS. Every step from designing metallurgical specification, heat treatment, Grinding and inspection is carefully controlled. The blades are standardized and are easily replaced. Accurate Gauging: The rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheets being cut. Lubrication: Single shot lubricator provides oil to all the lubrication points, where necessary. Drive: Drive is through V-Belts on flywheel and a reduction gears are made of steel, hob cut for smooth and longer life.

...more

hand press brakes

Our Heavy Duty Hand Press Brake Machines are made from M.S. Material and Mainly useful for any kind of Steel Furniture Industries. It is useful for Half Round and Right Angel Bending. Side Walls: Made from mild steel plate. Vertical and Horizontal supports are provided for more strength. Screws: Made from mild steel with square thick threads. Upper Beam: Made from Heavy Steel Plate. All surfaces are well surfaced to get accuracy. V-Block:Provided with 5 grooves for various sizes of job. Knife: Made from mild steel and sharpened up to 20o after sufficient machining.

...more

extra moulding machine

Machines are specially design to Heavy Duty the various Job requirements in Wood Working Industries. Machines are manufactured with general, rigidity and strength to with stand the heavy strains wear and tear of long use. We want to achieve satisfaction through our quality products also we look forward to enhance relationship with our Customers as well as attract new Business Relationship.

...more

cone pulley shaping machine

Our Shaping Machines are specialy designed to Heavy Duty the Various Job requirement in a workshop. Shaping Machines are manufactured with general rigidity, hardness and strength to with stand the heavy strains wear & tear of long use. For maintanance of Original accuracy for a longer period every part is made out of selected materials properly treated and skillfully machined in accurate aligment. The Machine has been designed for long continuous service without adjustment.

...more

Close Centre Power Chuck

Close centre wedge hook type power chucks are cost effective solution for universal machining where thru-hole is not essential. SPECIAL FEATURES:- Constant accuracy & high endurance - Strong Gripping - Available in 2, 3 & 4 Jaw configurations

...more

C-Type Power Press Machine

FRAME: The frame is made of steel construction and their heavy cross section and rigiddesign assure minimum deflection and accurate alignment cast iron legs will be supplied up to 30 ton press. CRANK SHAFT: Crank shaft materials are made of special alloy steel to withstand the effective loadsitted in busher with high accuracy. GEARS & CLUTCH: The gears are made of cast steel or fabricated and it teeth are generated by hobbing the clutch is provided of pin/rolling key type also it is rigid and well supported for the mass production clutch can gives continuous stroke. FLYWHEEL: The flywheel is made of high grade cast iron and is balanced for strong and releasing adequate energy for the pressing operations. LUBRICATION: An accurate lubrication system has been proved for lubrications the sliding surface and moving parts. TABLE & RAM: Table and ram are made of high grade heavy duty cast iron & properly seasoned. They are perfactly aligned to bach other to obtain high accuracy & precision press operation.

...more

Belter Machine

manufactured with general, rigidity and strength to with stand the heavy strains wear and tear of long use. We want to achieve satisfaction through our quality products also we look forward to enhance relationship with our Customers as well as attract new Business Relationship.

Belt Size : 1200 x 150mm

...more

Abrasive Belt Grinders

Versatile machine generally requested for Forge Shops, Press Shops, Ferrous & non Ferrous Foundries, Fabrication Shops, Engineering Industries, Plastic & Glass Industries, Rubber & Leather Industries and wood Industries. Rate of material removal is optimum. Excellent ground finish obtained. High rate of production. Machines available in four models i.e. Single Ended, Double Ended, Lathe Mounting and Multipurpose Combination machine. Lathe Mounting belt grinding machines are designed to grind and polish shafts, rollers, cyclinders for plastic industries, textile screw etc. in this model the job will rotate between centers and the machine is mounted on lathe carriage. Combination Multipurpose machines are universal machines where both wheel grinding and belt grinding jobs can be carried out. Use of best quality stamping and diecast rotors. Dynamically Balanced rotor minimise vibrations and ensure smooth running. Telescopic tendering arm for belt tensioning. Construction of the machines are made sturdy and robust to offer vibration free performance. Machine provided with one no. Abrasive Belt, Serrated rubber contact wheel, Rotaty Switch / Starter and Safety Belt Guard. Combination Multipurpose machine is with abrasive belt assembly on one side and Grinding Wheel on other side. Machines are available in Bench type or Pedestal type. Use of high quality grease for lubrication. RECOMMENDED USE OF GREASE LITHON 3 OR EQUIVALENT. All machines are subject to rigid quality control tests. Machines of different voltage and different frequency can be supplied against specific orders. All machines carry warranty (except ball bearings) against any manufacturing defect as per the warranty terms prevailing of the company. No warranty for wear and tear items.

...moreBe first to Rate

Rate ThisOpening Hours