Mould For Plastic Moulding Process

Get Price Quote

With our inventory management system, we are capable to undertake urgent and massive requirements of the buyers at a time. We ensure complete contentment to the clients by delivering only flawless range of goods as we store the complete batch in our capacious warehousing unit that is well-structured and maintained.

Plastic Injection Molds

50,000 - 100,000 Per piece

5000 Piece (MOQ)

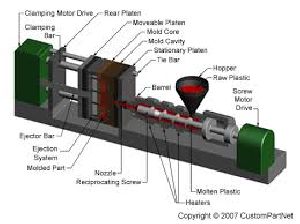

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, Where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers that do not melt during the injection moulding of some lower-temperature thermoplastics, can be used for some simple injection moulds. We can deliver the molding part as per your requirements with our best quality standards. We also provide quality testing facilities. We can assist you with design, engineering and quality standards. For which we have a molding machine. We committed to delivering high quality molding parts to our customers. We also have testing facilities for failure testing. We also provide engineering support for that.

Best Deals from Plastic Moulds

Plastic Injection Molds

Get Price Quote

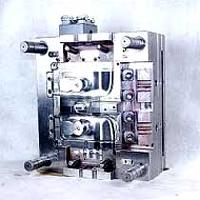

Plastic Injection Moulds supplied by us are of superior quality and can be easily handled and operated with higher production rate. Manufactured using superior quality raw materials, the Plastic Injection Moulds are highly durable and efficient. Applications General EngineeringMedical IndustryHouse hold applications

Plastic Moulds

Get Price Quote

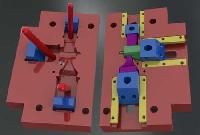

Known to be a reputed Manufacturer & Supplier of Plastic Moulds, we offer a unique combination of unmatched quality and durability. Our Plastic Moulds are in huge demand among our clients across the Indian Subcontinent. The high quality of material used in manufacturing & fabricating these Plastic Moulds, further lend these long lasting features. These Plastic Moulds are available in variant array of sizes and shapes. Our technicians hold rich expertise in customizing the Plastic Moulds as per the clients̢۪ specific requirements. Why Our Plastic Moulds? Good hardnessHigh toughnessGood polish abilityHigh wear and corrosion resistanceSurface texture propertiesNegligible dimensional changes in heat treatment

Plastic Moulding Services

Get Price Quote

Plastic Moulding Services, plastic moulding job works

plastic molding dies

Get Price Quote

plastic molding dies, Dies, Sheet Metal Cutting Dies

Plastic Moulding Dies

Get Price Quote

Plastic Moulding Dies, Investment Casting Dies, Injection Moulding Dies

Chequered Tiles Moulds

Get Price Quote

Chequered Tiles Moulds, High Pressure Paver Block Making Machine, cosmo paver

Plastic Injection Moulding

Get Price Quote

Plastic Injection Moulding, injection moulding machinery

UPVC Die Mould

Get Price Quote

UPVC Die Mould

Plastic Mould

Get Price Quote

Plastic Mould

Plastic Moulding Dies

Get Price Quote

Plastic Moulding Dies, Investment Casting, dies casting, sand casting die

Plastic Moulds

Get Price Quote

Plastic Moulds, Dies

Plastic Injection Moulds

Get Price Quote

Plastic Injection Moulds, General Engineering Components, Railway Components

plastic dyes molds

Get Price Quote

plastic dyes molds, Color Dyes, Investment Casting