Plastic Injection Moulding Machines

Get Price Quote

We offer Plastic Injection Moulding Machines. CPVC Ball Valve Injection Molding Machine We manufacture CPVC ball Valve making Plastic Injection Molding Machine, generally vertical screw type plastic injection molding machine have been used for CPVC different model are available from 100 Gm to 3000 Gm, with Semi Automatic & Fully Automatic, In Horizontal Injection Molding machine, CPVC ball valve machine is available from 50 Ton to 450 Ton depending on the customers requirems,

Plastic Injection Moulding Machine

150,000 - 1,000,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Plastic Processing Machinery

Plastic Vertical Moulding Machine

Get Price Quote

Upvc-cpvc Type Plastic Injection Moulding Machine

1,500,000 - 6,000,000 Per no.

1 no. (MOQ)

Pet Bottle Recycling Machine

7,200,000 Per Piece

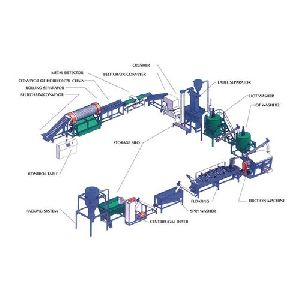

Pet Bottles Recycling Plant

Get Price Quote

1000 kg per hour capacity pet bottles recycling plant for sale, installed in 2013, total power load 232 hp complete line from bale breaking, washing to material bagging system related fixtures, accessories, cables and panel board, in excellent working condition.

Plastic Tap Shower

5 Per Piece

Vertical Plastic Mixer

75,000 Per Piece

1 Piece(s) (MOQ)

used plastic injection moulding machine

Get Price Quote

Used plastic injection moulding machine Five Stage Reduced Injection Pressure System, Linear Scale for Position Based Functions, Five Stage Reduced Injection Speed System.

VHF Series Plastic Injection Moulding Machine

Get Price Quote

VHF Series Plastic Injection Moulding Machine that we offer is gaining high popularity due to its high performance, smooth functioning and sturdy construction. We are one of the prominent Manufacturers, Exporters and Suppliers of Plastic Injection Moulding Machine from Gujarat, India. The manufacturing of our Plastic Injection Moulding Machine is done under the supervision of experts. Thus, buying Plastic Injection Moulding Machine from us will be the safest option for the buyers.

Agglomerator

Get Price Quote

The Agglomerator operates in "batches" and the processing chamber is loaded before and during the process. The high-energy-blades shred the plastics loaded material and press it under the rotor due to its design. The friction heats being generated during the operation . which heats up the plastics material up to the processing temperature. At this temperature the material becomes highly viscous. Subsequently cold water is injected into the process which causes the material to densify.

Plastic Recycling Machine

Get Price Quote

Our granules force speeder extruder machine recycling plant specially design for light weight material(plastic glass, cup etc). It is easy to operate and gives you maintenance-free constant high-quality granules. Anglo or grinder are not required with this machine. Ld liner waste feeding is possible which decrease cost of manpower, electricity and increase granules quality by eliminating anglo and grinder process. Recycling material pp hdpe ldpe bopp and more

plastic extrusion machines

Get Price Quote

Ocean Extrusions Pvt. Ltd. is a leading Plastic Extrusion Machinery Manufacturer & Exporter, having core expertise in comprehensive range of Extrusion Machinery for Plastic including Plastic Extruder such as Multi Layer Blown Film Plant, Mono Layer Blown Film Plant, Two Layer Blown Film Plant, Air Bubble Sheet Plant, Raffia Tape Stretching Plant, Extrusion Coating Lamination Plant, Co-Extrusion Blown Film Plant, PP-TQ Blown Film Plant, PVC Blown Film Plant, PPHDPE Monofilament Plant, Synthetic String (Sutli) Making Plant, PP Box Strapping Line, HDPE Box Strapping Line, PET Box Strapping Line, HDPE Blow Molding Machine, PPLD Reprocessing Granules Making Machine, PPLD Waste Washing Line, Die Face Cutter Reprocess Plant, Mother Baby Reprocess Plant, PET Reprocess Granules Making Machine, PET Waste Washing Line, Cast Stretch Film Making Plant. Ocean extrusions Pvt. Ltd. is a well known trusted name for providing customized solutions of Plastic Extrusion Machinery.

Plastic Extrusion Machine

Get Price Quote

DOUBLE WALL CORRUGATED PIPE PLANT SIZE FROM 50MM TO 150MM

Blown Film Extrusion Lines

Get Price Quote

blown film lines are available with outputs ranging from 30 kghr to 1000 kghr and lay-flat widths ranging from 50 mm to 5000 mm for processing polymers as diverse as LD, LLD, HM - HDPE, PP. FOILEX – mono layer blown film lines are also available in special configurations to process HDPE rich films both through high stalk bubble and low frost line height bubbles.

Rotomolding Rotational Moulding Machine

800,000 Per Piece

Plastic Granules Processing Machine

950,000 Per Set

1 Set(s) (MOQ)

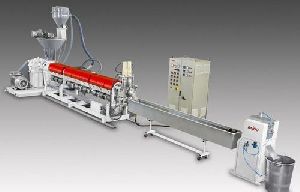

Plastic Extruder

Get Price Quote

Ocean offers various models for palletizing plant to make granules form resin in various range in screw diameter 75mm, 90mm and 100mm with without vent system screw and barrel, die and pattletizer.

Agglomerator

Get Price Quote

Specification Agglomerator for recycling New type of agglo which Separate Dust from Waste (Rafia Model Only) Run with only 4 Blades Once Grinded Blade can be used twice Foundation is not Necessary 100% Guarantee of HD/PP Rafia Model 70 to 80 Kgs/hr-024 Model Maintenance Free

plastic extrusion machines

Get Price Quote

Pipe Boring Machine

Get Price Quote

foam sheet extrusion line

Get Price Quote

1 Piece(s) (MOQ)

Brief specifications: a. screw diameter mm 90 & 114 b. screw length d 38 & 31 c. maximum sheet width mm 1100 d. foamed sheet thickness range mm 1.5 to 5 e. maximum output kg hr 250 f. line speed mtsmin 5-45 g. total connected load kw 215* h. line dimension (lxwxh) mm 21000 x 4500 x 3500 features: high speed sefty features included lewa pump power efficient lower dencity foam sheet quality-tested durable reliable

Plastic Extruder

Get Price Quote

PVC Extruder Machine is used extensively for mixing, compounding or reacting polymeric materials. The flexibility of twin screw extrusion equipment allows this operation to be designed specifically for the formulation being processed. For example, the two screws may be co-rotating or Counter-rotating, intermeshing or non intermeshing. In addition, the configurations of the screws themselves may be varied using forward conveying elements, reverse conveying elements, kneading blocks, and other designs in order to achieve particular mixing characteristics.

FIBRILLATING MACHINE FOR PLASTIC TAPE

Get Price Quote

We are main supplier of this product.

Plastic Mixer Machine

Get Price Quote

Plastic mixer unit: to mix various types of plastic material or plastic products which is as per application.

Agglomerator

Get Price Quote

Use to making glue from film waste to feed in extruder machine. Faster production Heavu Duty Construction Machine controls are equipped with necessary interlocking, safety devices with indicators and alarm.

Servo Thermoforming Machine

2,900,000 Per Piece

We are one of the leading organization engaged in providing excellent quality Servo Thermoforming Machines, which are manufactured by using high grade material. These Servo Thermoforming Machines are widely appreciated by our clients which are situated all round the nation. High in demand, these Servo Thermoforming Machines are available at most reasonable prices. Specifications: Capacity : 30 TPM Strokes: 45 Cyclesminute Material: PP HIPS PET.

plastic pipe extruder

Get Price Quote

Thermoforming Machine

Get Price Quote

We are an esteemed Manufacturer and Supplier of top-notch Thermoforming Machine based in Gujarat, India. The Thermoforming Machine we offer has a high industrial usage and is widely preferred by our customers through the length and breadth of the country. It is known for its long life and efficient operation, making it one of the best in the market. We offer the Thermoforming Machine at best prices.

Thermoforming Glass Machine

Get Price Quote

Dispocon vacuum formers are exceptionally sturdy, durable and low maintenance machines firmly established as industry's most energy efficient and least vibrating vacuum formers with patented trim press. Rajoo is one of the largest exporters of thermoforming machines and plastic cup making machine suppliers all over the world.