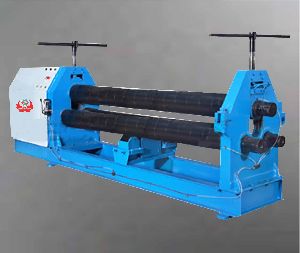

Roll Plate Bending Machine

Get Price Quote

With the support of our engineers, we are able to provide high performing Roll Plate Bending Machine to the clients. Roll Plate Bending Machine is assembled by making use of sophisticated components that ensure efficient performance, subsequently increases production capacity. Conical bending without any extra attachments can be done by Roll Plate Bending Machine. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Highlights Robust construction Smooth working Efficient design Longer service life Specifications The Pinch Cum Puramid Principle The machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll pinch type machines. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. An error in pre pinching can be corrected even after the shell is completed. It can pre-pinch and roll the plate without removing the plate from machine after first insertion. Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates. Cone Bending : The Machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Features Top roll drive for rolling thin plates. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. Plate Squaring(aligning) arrangement. Small dia. Top roll for small shell rolling (for reduced capacity). The Symmetrical Three Roll Principle of Plate Pre-Prinching & Rolling The plate is first lightly rolled over its full length. One of the bottom roll is brought near the top roll and plate edge is brought close to the tangent point. By lifting the other bottom roll, plate edge is pre-bent (pre-pinched) The Positions of bottom rolls are reversed (interchanged) for pre-bending second edge of the plate. Note that both the edges are pre-bent without turning the plate around. The rolls are brought in pyramid formation and cylinder is completed. Note that an error in pre-pinching can be corrected even at this stage.

Plate Bending Machine

Get Price Quote

Easy to maintain and useful for various jobs. Modern design and rigid structure. So simple mechanism that even semi-skilled worker can do accurate job. Very useful for g etting Cylindrical shapes and better performance. It works with 3 Rolls pyramid principal. Bottom rolls are fixed and driven by Gears and warm Reduction Gear Box. Top roll rotates in fixed position and can be adjusted up & down manually by adjustable screws, in mechanical version and by Hydraulic system & cylinder In Hydro mechanical version. Housing are made from M. S. plate of suitable strength and mounted on heavy base frame, Rolls are made from forget steel and perfectly machined for accurate result. For correct feeding and grip axial grooves are provided on botton rolls. Screw jack/extra Hydraulic cylinder is given to keep top roll horizontal when formed shell is to take out. Our machines are fitted with Electric Brake Motor and Movable Control Panel, so that machine can be stopped at any stage of operation, hence the shape in rolling as per requirement is most possible and due to the movable control panel machine can be operated very easily. Machine is fitted with total 2 nos. Gear Box, Electric Brake Motor, Push Button Type Movable operating switch board and Electric control panel for easy & safe operation. We only offer the machine with double Gear box, one is warm Gear box and another is spur reduction gear box, due to this the fatigue in operation and over load on electric motor and warm reduction Gear box is totally avoided even when machine is Working in over capacity and more over bending operation be come more easy. Whole machine is made out of quality prime materials. Only Top Roll Pressing (Up-Down) and opening closing of drop end are through hydraulic system & cylinders all other operations are carried out mechanically in hydro-mechanical version. In mechanical version Top Roll Pressing is manually by means of screws and opening/closing of end-dropper is manual or motorized. Hydro- Mechanical Machine required lees man power compare to mechanical version, the same directly Effect your production rate and finish job value. Apart from above the rates are more competitive in its range.

Best Deals from Plate Bending Machine

Hydraulic Plate Bending Machine

600,000 Per Piece

Mechanical 3/4 Roll Plate Bending Machine

Get Price Quote

Specifications: The Pinch Cum Puramid Principle The machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll pinch type machines. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. An error in pre pinching can be corrected even after the shell is completed. It can pre-pinch and roll the plate without removing the plate from machine after first insertion. Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates. Cone Bending The Machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Salient Features Top roll drive for rolling thin plates. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. Plate Squaring(aligning) arrangement. Small dia. Top roll for small shell rolling (for reduced capacity).

Plate Bending Machine

96,000 - 1,567,000 Per pc

Hydraulic Plate Bending Machines

Get Price Quote

Pyramid base principle 3 & 4 Roll Hydraulic Plate Bending Machine Used for roll bending of plates with pre-pinching Product like Vessel & Tanks, Cone, Silos, Over & Under Storage Tanks, Heavy Transmission Pipe, etc.

Hydraulic Plate Bending Machine

Get Price Quote

Manufacturer of milestone brand high quality hydraulic shearing machine, Press Brake, Shearing Machine and Plate Bending Machine,plate rolling machine,cutting machine,cuff & collar cutting press and all types of Workshop Machinery & Sheet Metal forming machinery with reliable prize.

pyramid type plate bending machine

Get Price Quote

pyramid type plate bending machine, Hydraulic Press Brake, Hydraulic Press