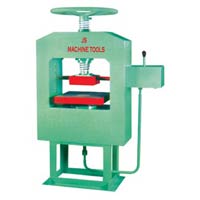

Roll Press Machine

Get Price Quote

500 Piece(s) (MOQ)

We hold enough expertise to fabricate high-performance Roll Press Machines (without cover regular) and make them available to various parts of the country and abroad in a time-efficient manner. We are counted among the premier Manufacturers, Exporters, and Suppliers of Roll Press Machines from Gujarat, India. We fabricate them from high-grade components and materials, in compliance with the standards. And the machine is made obtainable in varying specifications, as per the client’s requirements.

SS KITCHEN PRESS

219 Per Piece

72 Piece(s) (MOQ)

Best Deals from Pressing Machine

Pneumatic Paneer Press Machine

Get Price Quote

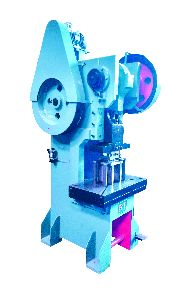

Heavy Duty Power Press Machines

Get Price Quote

Roll Press Machine

19,500 Per Piece

5 Piece(s) (MOQ)

Mechanical Press Brake Machine

Get Price Quote

Mechanical press brake machine Mechanical Press Brakes are designed and developed through structural analysis technique for continuous production, accuracy & repeatability, Following are the salient features of the Machine :Frame is made of M S Steel Plate and is of interlocked design. It is strain free and supports Ram & Bed under permissible load condition.

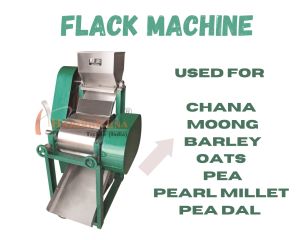

Chana Pressing Machine

200,000 Per Piece

1 Piece (MOQ)

Mechanical Press Brake Machine

Get Price Quote

Based in Rajkot, we are a prominent Manufacturer and Supplier of Mechanical Press Brake. The design of Mechanical Press Brake is based on innovative engineering. Further, Mechanical Press Brake is configured with advanced technology which efficiently boosts production capacity of unit. Highlights Robust construction Smooth working Efficient design Longer service life Details Frame : Frame is of robust fabricated steel construction of rigid and interlocked design, It is strain- free and supports the ram and bed against undesired deflection under permissible loding condition. Ram and Bed : Made from steel Plates of suitable thickness, machined for straightness and parallelism of the working surfaces. Ram is guided and supported throughout the stroke by accurately machined guided ways. Drive System : Power is transmitted to the ram through two individual geardrives for uniform load distribution throughout the length. This also reduces the torsional stresses on the eccentric shaft. Electric motor used is of sufficient H.P. which reduces slowdown of flywheel and increases energy available per stroke. The gear and pinion are made out of carbon/alloy steel. Ram Adjustment : Motorised ram adjustment through a simple drive mechanism, facilitates quick bending angle adjustment. Angular ram adjustment is made simple by incorporating a spring loaded dog clutch. Clutch and Brake : All series of press brakes are provided with high-torque low-inertia friction clutch, synchronized with heavy duty mechanical brakes ensuring immediate braking of ram on releasing the pedal. Clutch operating levers are designed in such a way that minimum engaging force is required at the pedal. Features Foot Pedal and Die Block Lifting Link. Fly Wheel & Gear Guard. Self Lubrication System. Motor Pully. Stroke counter. Standard �V� Block and Punch. Motor Mounting Bracket. Options Motorised Back Guage. Automatic Lubrication System ee-Belts. Electric Motor & Starter / Control Panal Board. Squaring Guage System. Various type of Die & Punch. Foundation Bolts. All Dimensions are in mm. Power Supply 400/440 volts, 3 Phase, 50 Cycle. As day to day improvements are contemplated for better performance of the machine. We reserve the rights to alter the specifications without prior notice. All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation.

10 Ton Power Press Machine

Get Price Quote

We are offering of "fmt" brand C-Type & H-type power press from the range of 05 tons to 200 Tons. We are in this field since last 31 years due to quality, workmanship & accuracy. FMT Brand fabricated steel plate body Power Presses for the best Quality & precise wotk with choice of mechanical / electromagnetic / pneumatic clutch for your heavy jobs.

Clutch Operated Power Press Machine

75,000 - 2,500,000 Per Piece

1 Piece(s) (MOQ)

Interlocked Fully Steel Plate Body Heavy Duty Gap Frame & H Frame Precision Power Press.All Shafts Made From Carbon Steel Material And Precision Grinding Size Machine

Power Press Machine

Get Price Quote

1 Piece(s) (MOQ)

Plastic Sheet Press machine

Get Price Quote

Mini Hydraulic Press Brake Machine

220,000 Per Piece

1 Piece(s) (MOQ)

Hydraulic Hand Press Machine

Get Price Quote

Hydraulic hand press machine Designed from Mild Steel & are connected with the lower beam. Fabricated from heavy steel plate machining its every surface ensuring perfact job as it functions in the slide. Fabricated from mild steel and sharpened up to 20° after machining.

Automatic Power Press Machine

Get Price Quote

Automatic Power Press Machine that we manufacture and supply features an inclinable type fixed body. It features steel frame construction and manufactured using rolled steel plates with suitable cross ribbings. Our Automatic Power Press Machine presses up to 30 T and it will be supplied with C.I. legs. Proper alignment of the frame is ensured by machining. Automatic Power Press Machine that we make available is featured with clutch, crank shaft, flywheel, gears, etc., for proper functionality. Features: Clutch : The clutch is of Pin/rolling key-type. The clutch is rigid and well supported the clutch given continuous strokes for mass production. Crank Shaft : Crank Shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy. Flywheel : Properly sized flywheel is made of high grade cast iron. For shoring and releasing adequate energy for the pressing operations, and properly balanced for smooth running. Gears : Gears and of steel cast or fabricated. Gear teeth are generated by precision nobbing machine. Table & Ram : Table and ram made of high grade heavy duty cast iron & properly seasoned. They are perfectly aligned to each other to obtain high accuracy & precision press operation. Lubrication : An efficient shot lubrication system has been provided for lubricating the sliding surfaces and moving parts. The lubricant is applied by hand pump. Inclining : Inclinable type presses proceed with inclining mechanism which can be easily set and locked in position. Mechanism : By Spanners Within minutes. The press is so designed that even in maximum inclined position, it is stable under heavy pressing load.

C Type Power Press Machine

35,000 Per Piece

1 Piece(s) (MOQ)

Press Brake Machine

400,000 Per Piece

Dates tamarind cake pressing machine

Get Price Quote

1 Unit (MOQ)

Pneumatic Power Press Machine

Get Price Quote

Frame Contraction: Frame is fabricated from IS-2062 graded rolled steel plates table and cutting beam deeply reinforced and fines machines after stress reliving. The interlocked design put the direct support to frame. These frames are strain free and eliminate welds at load supports. Thus the accuracy of the machine is never disturbed. Table & Slide (Ram): Table and Slide are made of high grade heavy duty cast iron/steel fabricated and properly seasoned. They are perfectly aligned, to each other to obtain high accuracy and precision press operation. Cylinder: The cylinder bodies are precisely made from forged steel material duly bored and fine honed or long sealing life. The piston rods are made from EN-8 material having low carbon contents. The piston rod is hard chrome platted (0.200 micron). Hydraulic System: The compact blocks eliminate the leakage chances and also reduces the hydraulic pipes. This low noise hydraulic system is placed on the rear side of machine, on the rear side of machine, on top between two side plates. Pressure relief values is provided to safe guard the system and machine from overload. The hydraulic system is driven by an electric motor of reputed brand and is coupled with a pump capable if generating more than the required pressure. Pressure gauge for system pressure, back pressure and holding pressure are providing on top of oil tank for quick reference. Electrical Control Panel: The electrical control panel is located on the left hand side of the machine. It is assembled from the internationally reputed parts for consistent performance, reliability and availability, if need to be replaced. It is wire cleanly and labeled/ferruled properly as per the international practices to help easily locates any fault and replaces components conveniently.

Oil Hydraulic Press Machine

Get Price Quote

The body of our Oil Hydraulic Press Machine is fabricated using M.S Steel, piston from Hard Chrome and Wiper on the cylinder top. The production capacity of Oil Hydraulic Press Machine is 1200 per Shift. The tile so produces by Oil Hydraulic Press Machine would be having dimensions like 375mm x 375mm. Specifications : Production Capacity : 1200 per Shift Capacity : Size of Tiles up to- 375mm x 375mm

Power Press Machine

300,000 Per Piece

Power Press Machine

345,000 Per Piece

1 Piece (MOQ)

C Type Power Press Machine

Get Price Quote

Goldsmith Hydraulic Press Machine

Get Price Quote

This is a steel fabricated body hydraulically operated 300 tons press specially designed for minting gold and silver coins and medals. This hydraulic coin minting press is an upstroke Coining press with higher ram travel speed and with extra hydraulic cylinder for return stroke to increase the production. The hydraulic Coin minting press is equipped with hydraulic Power Pack consisting of Piston Pump, Electric Control panel board operated directional Control Valve, relief Valve, Pressure Gauge and standard hydraulic accessories. This hydraulic Coining Press can be operated through the control panel board or manually with foot pedals and has the provision to adjust the final coining pressure. A timer is provided to adjust the time for which the pressure remains applied before return stroke. Our standard version Hydraulic Coining Press is available in four models: 50 Tons, 100 Tons, 200 Tons and 300 Tons Capacity.

Cotton Baling Revolving Press Machine

Get Price Quote

Press Brake Machine

Get Price Quote

We are a trusted supplier of Press Brake Machine, providing the lucrative deals to the widespread customers at easy terms. To handle both automated inbound and outbound orders, we have exceptional warehousing solutions. We keep the wide array of products sorted in the warehouse to make sure that the delivery commences systematically. Product Details : Machine Type - Lathe Machine,Milling Machine,Drilling Machine,Boring Machine Operation Mode - Semi Automatic Service Location - Any Where in India Approx Price : Rs 3,000 / Piece

Die Press vulcanizer

Get Price Quote

We offer superlative quality Die Press i.e. Vulcanizing Press of various sizes, capacities and dimensions in different models. We have uniquely positioned ourselves as the eminent Die Press (Vulcanising Press) manufacturer and one of the predominant suppliers in India. Their solid and robust structure enhances its performance and longevity. We also manufacture Die Press vulcanizing Press as per the requirements of the clients. We have a specially trained team for manufacturing rubber vulcanizer machine which is also examined after manufacturing. With all this we are paramount vulcanization machine manufacturer and suppliers from India Gujarat Rajkot to all over the world. Die Press (vulcanizing Press) is first unit of Gold Casting Machine with the help of Die Press (vulcanizing Press) one can vulcanize rubber mould(die) of any jewelery design. In jewellery casting process die making is important part. As we are leading Jewellery casting machine Manufacturer we provide highly accurate Jewellery casting technique to our customer. However jewelry mould maker requires high skill & knowledge for Cutting Rubber Mould. Rubber mould cutting technique requires high skill.

briquetting press machine

Get Price Quote

Our Briquettes Machine 75MM MODEL is the ideal choice of the manufacturers looking for output in the range of 800-1000 kg/hr. and not yet ready for the investment in installation of JUMBO 9075 MODEL. This machine is also supported by Hammer Mill (Powder Making Unit) that breaks raw material in powdery form that is suitable for final process of biomass Briquettes production. Input Bulk Density 140 To 200 Kg/M3. Briquettes have high specific density (1200 Kg/m3) and bulk density (800 Kg/m3) compared to 60 to 180 Kg/m3 of loose biomass.

C Type Power Press Machine

80,000 Per Piece

Power Press Machine

Get Price Quote