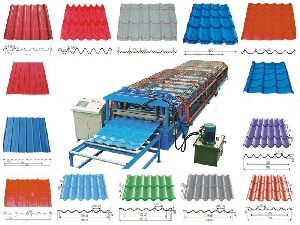

Light Roll Forming Machine

Get Price Quote

The company is a prominent Manufacturer, Exporter & Supplier of Light Roll Forming Machine. Our team of experts manufactures the Light Roll Forming Machine using cutting-edge technology and superior grade parts and components. The Light Roll Forming Machine is perfectly designed, excellently finished and is durable and reliable. We supply efficient Light Roll Forming Machine all across the world at the market leading prices. Details : The frame of the economical trapez rollformer is solid and the shafts are attached to the frame.It rollforms the raw materials to thicknesses of between 0.45 0.6 mm.Production speed varies from 15 to 20 meters per minute.Shafts attached to adjustable bearing blocks which enable to rollform the raw material up to a thickness of 0.9 mm.A user friendly control unit is provided with an LED-monitor and the necessary electrical components for manual and automatic line operation.It controls the operation of the roll forming machine and the cutter.Up to 8 different lengths and 999 pieces per length can be programmed.An advanced Programmable Logic Controller (PLC) control unit is provided with an LCD-monitor and the necessary electrical components for manual and automatic line operation.Controlled operation of the roll forming machine, cutter and stacker.Upto l0 different lengths and 1000 pieces can be programmed.Efficient production speed of 40 metres per minute guarantees maximum output.Slitting Line versions : Pull through and Loop type with Felt Tension PressSlitting Line setup includes Coil Car, Uncoiler, Slitter, Scrap Winder, Felt Tension Pres, Recoiler and Turn Table.Slit Cutters made of HCHCr steel hardened 8 grounds to close tolerance for Burr free cutting & longer life.Specially designed PTFE coated spacers provided to set Cutters to any width.Automation of various levels offered in set up of Cutters.Scrap Winder 8 Scrap Chopper options are available as per requirements.Felt Tension Press designed to provide tight 8 camber free coil winding.8 supply Automation can be developed at the output end like Coil Down Laying, Strapping, Sorting, Numbering, etc.Slitting Line available in standard versionsMade-to-order line also designed as per specific needs.

Roll Forming Machine

Get Price Quote

Best Deals from Roll Forming Machine

Roll Forming Machine

Get Price Quote

We are offering precision engineered Roll Forming Machine specially designed for large to small scale production volumes. The Decoilers are available in 5 to 10 ton coils to meet your exact requirements. Also, an automated Stacker can be equipped with either a belt conveyor or a motorized roller line. We also offer a wide range of Uncoilers to meet specific need for hydraulic or manually expandable Mandrel. Parts which are used in our control units are universal and can be easily found worldwide. We also provide tailor made Roll Forming Machine, for meeting specific needs like Hydraulic Lifted single stage Roll Former for Transformer Radiator Plate. Clients can avail from us this Roll forming machine in varied widths and heights, which is produced by computer control, to input various parameters rather changing the tools. This type of machinery is designed to roll form both edges of sheet panel, where main machine is fixed on one side and other side is adjustable to suit for various widths of sheet panel. Features Efficient and automatedReliable and powerful DecoilerEssential part of fluent operationAutomated StackerEquipped with a pre-cutterNo waste leftMeets safety requirementsCost-effectiveDimensional consistency Used For The Production Of Office furnitureSteel shelving systemCold storage panelsOther industrial applications Technical specification Capacity : 7.5kwRoll Stations : 14Thickness : 0.35-0.42mmRoll Speed : 12m/min

Roll Forming Machine

Get Price Quote

Owing to our expertise in this domain, we have been able to offer our clients a finest quality range of Roll Forming Machine that is used for various heavy duty jobs. This machine is precisely engineered using high quality components under the supervision of our technocrats.Roll Forming Machine has many specific attributes like robust design, heavy duty steel plate body, easy operation, high efficiency, supreme performance and longer functional life. The offered machine is available in various specifications and can also be customized at market leading prices.

Corrugated Roll Forming Machine

Get Price Quote

We are the one of the leading Manufacturers, Exporters and Suppliers of Corrugated Roll Forming Machine. Each Corrugated Roll Forming Machine is constructed with the use of best quality galvanized steel sheet, colored armor plate or aluminum plate as the material plate. The finished products of Corrugated Roll Forming Machine are used as the roof tile and wall panel outside of building. This machine�s processing length is unlimited. The machine can make panel automatically. Users just have to set data on the computer control cabinet and press a button. Our quality checking team tests every Corrugated Roll Forming Machine on various parameters. Our Corrugated Roll Forming Machine is the best in terms of performance, quality, strength and resilience. We deliver Corrugated Roll Forming Machines timely and at reasonable prices to our clients. Features Robust in structureResistant to easy wear and tearEasy to operateAccurate dimensionCost effectiveness

Roll Forming Machines

Get Price Quote

O cater the variegated demands of our precious clients, our organization known as a leading exporter, manufacturer & supplier of roof sheet roll forming machine in foshan, guangdong, china. Work material : steel in coil aluminum gi ppgi linear ceiling roll forming machine include main parts as below: a. De coiler b. Roll forming machine c. Automatic cutter d. Cutting mould e. Collecting stand. F. Plc

Guardrail Roll Forming Machine

Get Price Quote

D coiler 10 ton cap, Punching press 100 tone, Entry Gate withRoll Forming Line with 16 stations, 8 Gear Boxes & 15 H.P. electrical, Control Panel semi autoCutting Unit (Hydro.)Maximum sheet width that can be formed850 mm, Maximum sheet thickness in CRCA Strips that can be formed5 mm(M.S.), Horizontal distance between shafts500mm.

roll forming lines

Get Price Quote

roll forming lines, Cut To Length, slitting

Roll Forming Machine

Get Price Quote

Roll Forming Machine

Get Price Quote

pipe polishing machines

Mcb Channel Roll Forming Machine

Get Price Quote

Mcb Channel Roll Forming Machine

roll forming machinery

Get Price Quote

roll forming machinery, Rolling Shutter, Slitting Machine

roll forming machinery

Get Price Quote

roll forming machinery, Door Bolt, Curtain Finial