Hydro Mechanical Plate Rolling Machine

500,000 Per Units

1 Units (MOQ)

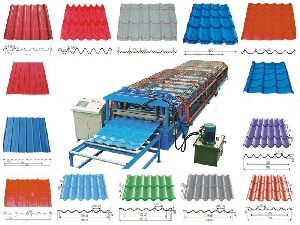

Light Roll Forming Machine

Get Price Quote

The company is a prominent Manufacturer, Exporter & Supplier of Light Roll Forming Machine. Our team of experts manufactures the Light Roll Forming Machine using cutting-edge technology and superior grade parts and components. The Light Roll Forming Machine is perfectly designed, excellently finished and is durable and reliable. We supply efficient Light Roll Forming Machine all across the world at the market leading prices. Details : The frame of the economical trapez rollformer is solid and the shafts are attached to the frame.It rollforms the raw materials to thicknesses of between 0.45 0.6 mm.Production speed varies from 15 to 20 meters per minute.Shafts attached to adjustable bearing blocks which enable to rollform the raw material up to a thickness of 0.9 mm.A user friendly control unit is provided with an LED-monitor and the necessary electrical components for manual and automatic line operation.It controls the operation of the roll forming machine and the cutter.Up to 8 different lengths and 999 pieces per length can be programmed.An advanced Programmable Logic Controller (PLC) control unit is provided with an LCD-monitor and the necessary electrical components for manual and automatic line operation.Controlled operation of the roll forming machine, cutter and stacker.Upto l0 different lengths and 1000 pieces can be programmed.Efficient production speed of 40 metres per minute guarantees maximum output.Slitting Line versions : Pull through and Loop type with Felt Tension PressSlitting Line setup includes Coil Car, Uncoiler, Slitter, Scrap Winder, Felt Tension Pres, Recoiler and Turn Table.Slit Cutters made of HCHCr steel hardened 8 grounds to close tolerance for Burr free cutting & longer life.Specially designed PTFE coated spacers provided to set Cutters to any width.Automation of various levels offered in set up of Cutters.Scrap Winder 8 Scrap Chopper options are available as per requirements.Felt Tension Press designed to provide tight 8 camber free coil winding.8 supply Automation can be developed at the output end like Coil Down Laying, Strapping, Sorting, Numbering, etc.Slitting Line available in standard versionsMade-to-order line also designed as per specific needs.

Best Deals from Rolling Machine

Roll Feeder Milling Machine

Get Price Quote

Ring Rolling Machines

Get Price Quote

We offer Ring Rolling Machines.

Plate roll

Get Price Quote

Hydraulic Plate Rolling Machine fabricated from IS-2062 graded rolled steel plates. Frame is deeply reinforced and fines machines after stress reliving. The interlocked design put the direct support to frame and closed box type. This frame is strain free and eliminates welds at load supports. Thus the accuracy of the machine is never disturbed.

Roll Forming Machine

Get Price Quote

Roll Forming Machine

Get Price Quote

Owing to our expertise in this domain, we have been able to offer our clients a finest quality range of Roll Forming Machine that is used for various heavy duty jobs. This machine is precisely engineered using high quality components under the supervision of our technocrats.Roll Forming Machine has many specific attributes like robust design, heavy duty steel plate body, easy operation, high efficiency, supreme performance and longer functional life. The offered machine is available in various specifications and can also be customized at market leading prices.

ring rolling machine

Get Price Quote

Roll Forming Machine

Get Price Quote

We are offering precision engineered Roll Forming Machine specially designed for large to small scale production volumes. The Decoilers are available in 5 to 10 ton coils to meet your exact requirements. Also, an automated Stacker can be equipped with either a belt conveyor or a motorized roller line. We also offer a wide range of Uncoilers to meet specific need for hydraulic or manually expandable Mandrel. Parts which are used in our control units are universal and can be easily found worldwide. We also provide tailor made Roll Forming Machine, for meeting specific needs like Hydraulic Lifted single stage Roll Former for Transformer Radiator Plate. Clients can avail from us this Roll forming machine in varied widths and heights, which is produced by computer control, to input various parameters rather changing the tools. This type of machinery is designed to roll form both edges of sheet panel, where main machine is fixed on one side and other side is adjustable to suit for various widths of sheet panel. Features Efficient and automatedReliable and powerful DecoilerEssential part of fluent operationAutomated StackerEquipped with a pre-cutterNo waste leftMeets safety requirementsCost-effectiveDimensional consistency Used For The Production Of Office furnitureSteel shelving systemCold storage panelsOther industrial applications Technical specification Capacity : 7.5kwRoll Stations : 14Thickness : 0.35-0.42mmRoll Speed : 12m/min

TCP-H-1000 X 5000 CNC Roll Turning Lathe Machine

Get Price Quote

1 Piece (MOQ)

Optional Equipments : Hydraulic Quill Motorised Tailstock Steady Rest Motorised Turret Chip Conveyor Revolving Centre Tool Shank / Insert Stabilizer

roll press machines

Get Price Quote

Our firm is a prominent company, active in Manufacturing & Supplying a large array of Mini Roll Press in Rajkot, Gujarat, India. This press is produced using optimum quality components and cutting edge technology under the strict guidance of experienced experts. It is highly required for roll pressing work in various industries. We provide this press.

Mechanical Plate Rolling Machine

500,000 Per Piece

1 Piece (MOQ)

Highway Guardrail Roll Forming Machine

Get Price Quote

We are a well-established company engaged in manufacturing, supplying and exporting a range of Highway Guardrail Roll Forming Machine. The range of Highway Guardrail Roll Forming Machine made available by us is dimensionally accurate and functions well. Highlights Competitive pricesFunctions wellEasy to operateLow maintenance

Roller Grinder Machine

Get Price Quote

Being a quality conscious firm, we conduct strict quality checks for ensuring the product quality. Assistance from skilled professionals and brilliant packaging unit has enabled us to meet specific requirements of the clients. Besides this, we make sure that the material used for wrapping them is of high quality.

Roll Plate Bending Machine

Get Price Quote

With the support of our engineers, we are able to provide high performing Roll Plate Bending Machine to the clients. Roll Plate Bending Machine is assembled by making use of sophisticated components that ensure efficient performance, subsequently increases production capacity. Conical bending without any extra attachments can be done by Roll Plate Bending Machine. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Highlights Robust construction Smooth working Efficient design Longer service life Specifications The Pinch Cum Puramid Principle The machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll pinch type machines. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. An error in pre pinching can be corrected even after the shell is completed. It can pre-pinch and roll the plate without removing the plate from machine after first insertion. Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates. Cone Bending : The Machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Features Top roll drive for rolling thin plates. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. Plate Squaring(aligning) arrangement. Small dia. Top roll for small shell rolling (for reduced capacity). The Symmetrical Three Roll Principle of Plate Pre-Prinching & Rolling The plate is first lightly rolled over its full length. One of the bottom roll is brought near the top roll and plate edge is brought close to the tangent point. By lifting the other bottom roll, plate edge is pre-bent (pre-pinched) The Positions of bottom rolls are reversed (interchanged) for pre-bending second edge of the plate. Note that both the edges are pre-bent without turning the plate around. The rolls are brought in pyramid formation and cylinder is completed. Note that an error in pre-pinching can be corrected even at this stage.

3 & 4 Roll Plate Bending Machine

Get Price Quote

Pyramid base principle 3 & 4 Roll Hydraulic Plate Bending Machine Used for roll bending of plates with pre-pinching. Product like Vessel & Tanks, Cone, Silos, Over & Under Storage Tanks, Heavy Transmission Pipe, etc.

Papad Rolling Machine

18,880 Per Piece

Hydraulic Spinning Rolling Machine

Get Price Quote

MRM with 7 Rolls machine

Get Price Quote

Roll Forming Machines

Get Price Quote

O cater the variegated demands of our precious clients, our organization known as a leading exporter, manufacturer & supplier of roof sheet roll forming machine in foshan, guangdong, china. Work material : steel in coil aluminum gi ppgi linear ceiling roll forming machine include main parts as below: a. De coiler b. Roll forming machine c. Automatic cutter d. Cutting mould e. Collecting stand. F. Plc

SS Plate Rolling Machine

Get Price Quote

Wire roll press machine

Get Price Quote

Awelable in various size & model And also as per your requarmet For your special needs.

Plate Rolling Machine

Get Price Quote

Dear sir, manufacturer of milestone brand high quality hydraulic press, press brake, shearing machine and plate bending machine,hydraulic shearing and press break machine, workshop machinery & sheet metal products with reliable prize. due to good quality and workmanship and best performance our milestone brand has become very famous in many states throughout india. We ensure you the visit will enable you to know us and products better. We now therefore request you if you have any requirement of above noted machine please sense free to contact us. Your valued inquire will help us to establish good business relations with your reputed organization.

Hand Operated Jewellery Rolling Machine

14,947 Per Piece

Pillow Roll Packing Machine

299,000 Per Unit

1 Unit (MOQ)

Guardrail Roll Forming Machine

Get Price Quote

D coiler 10 ton cap, Punching press 100 tone, Entry Gate withRoll Forming Line with 16 stations, 8 Gear Boxes & 15 H.P. electrical, Control Panel semi autoCutting Unit (Hydro.)Maximum sheet width that can be formed850 mm, Maximum sheet thickness in CRCA Strips that can be formed5 mm(M.S.), Horizontal distance between shafts500mm.

Roll Press Machine

19,500 Per Piece

5 Piece(s) (MOQ)

Hydraulic / Mechanical 3/4 Roll Plate Bending Machine

Get Price Quote

Specifications: The Pinch Cum Puramid Principle The machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll pinch type machines. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. An error in pre pinching can be corrected even after the shell is completed. It can pre-pinch and roll the plate without removing the plate from machine after first insertion. Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates. Cone Bending The Machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Salient Features Top roll drive for rolling thin plates. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. Plate Squaring(aligning) arrangement. Small dia. Top roll for small shell rolling (for reduced capacity).

plate rolling

Get Price Quote

plate rolling, goldsmith machinery, Sheet Metal Machinery

Sheet Rolling Machine

300,000 Per Piece