Wire & Strip Forming Machine

We are a Rajkot based Manufacturer and Supplier of Wire & Strip Forming Machine. These Wire & Strip Forming Machines are designed with utmost precision for the total stability. Wire & Strip Forming Machine is configured with a touch screen software which ensures easy uses and productivity both in terms of quality and quantity. Wire & Strip Forming Machine is a fully automatic machines designed for the production of all types of strips. Salient Features Safety Detection for Material Disconnection & Jam Touch Screen Software Automatic Lubrication Fast production Rate Ideal for strip Precise & Stable Continuous Feeding Machine is fully automatic Easy to load strip

...more

Wire Forming Machine

we are manufactures wire forming machine the last 5 years, this is wire forming machine all type of customer requirement of design clients

...more

Under Crank Shearing Machine

Our zeal to achieve excellence enables us to design and develop efficient Under Crank Shearing Machine. Our Under Crank Shearing Machine is quality tested and promises remarkable workability at low operational cost. Configured with advanced technology, Under Crank Shearing Machine boosts productivity of shearing in any heavy metal industry. Highlights Robust construction Smooth working Efficient design Longer service life Details Frame : Rigid steel frame of Shubham Shears are optimally designed to avoid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by accurate machined guide ways ensuring proper clearance and clean cut. Hold � Down System : Spring loaded mechanical hold down pads hold the sheet security, to avoid slipping and bowing resulting in clean square cuts. Hold down units are provided with oversize pads to avoid impressions on sheet metal on request. Knives : Shubham Shears are provided with high quality single segment (HcHcr) Knives for longer tool life. Ease in assembling of knife reduces down-time. The knife blades are four edged. Lubrication : All bearing parts and guide surfaces are lubricated through hand-operated lubrication system. Mechanical Back Guage : This is a standard equipment provided on all Shubham Shears. Scale on the back guage gives instantaneous reading of distance between shear and back guage. Thus avoiding errors and maintenance encountered in electronic equipment. Finger Guard : Fitted in front of hold-down for operator protection without obstructing viewing. Features Foot Pedal. Fly Wheel & Gear Guard. Self Lubrication System Motor Pully A Pair of Four Edge Sher Blade Standard Front Guage Back Guage (Manual Operated) Options Motorised Back Guage. Automatic Lubrication System. Vee-Belts. Electric Motor & Starter / Control Panal Board. Squaring Guage System. Stroke Counter. Extension Squaring Arm. Hydraulic Holddown Pads (Cam-Pump). All Dimensions are in mm. Power Supply 400/440 volts, 3 Phase, 50 Cycle. As day to day improvements are contemplated for better performance of the machine. We reserve the rights to alter the specifications without prior notice. All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation

Type : Under Crank Shearing Machine

Weight : 100-1000kg

Voltage : 380V, 220V

Automatic Grade : Fully Automatic, Automatic

Driven Type : Elecric

Warranty : 1year

...more

Steel Sheet Slitting Machine

Placed amongst the foremost suppliers, we are a far famed for the outstanding Steel Sheet Slitting Machine. As a customer-focused firm, we strive hard to delight them with high quality range of products that are the perfect outcome of premium raw material and modern work methods.

Type : Steel Slitting Machine

Voltage : 220V, 380V

Rated Power : 3-6kw, 6-9kw

Automatic Grade : Automatic, Semi Automatic

Driven Type : Hydraulic

Warranty : 1year

...more

Roll Plate Bending Machine

With the support of our engineers, we are able to provide high performing Roll Plate Bending Machine to the clients. Roll Plate Bending Machine is assembled by making use of sophisticated components that ensure efficient performance, subsequently increases production capacity. Conical bending without any extra attachments can be done by Roll Plate Bending Machine. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Highlights Robust construction Smooth working Efficient design Longer service life Specifications The Pinch Cum Puramid Principle The machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll pinch type machines. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. An error in pre pinching can be corrected even after the shell is completed. It can pre-pinch and roll the plate without removing the plate from machine after first insertion. Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates. Cone Bending : The Machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. Features Top roll drive for rolling thin plates. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. Plate Squaring(aligning) arrangement. Small dia. Top roll for small shell rolling (for reduced capacity). The Symmetrical Three Roll Principle of Plate Pre-Prinching & Rolling The plate is first lightly rolled over its full length. One of the bottom roll is brought near the top roll and plate edge is brought close to the tangent point. By lifting the other bottom roll, plate edge is pre-bent (pre-pinched) The Positions of bottom rolls are reversed (interchanged) for pre-bending second edge of the plate. Note that both the edges are pre-bent without turning the plate around. The rolls are brought in pyramid formation and cylinder is completed. Note that an error in pre-pinching can be corrected even at this stage.

Warranty : 1year

Voltage : 110V, 220V

Weight : 100-1000kg

Type : Plate Bending Machine

...more

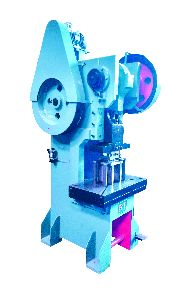

Power Press

We are offering power press. rt power press are designed and developed through years of experience in sheet metal working machines. Rt power press are widely accepted in industries for continuous production runs, and in areas requiring accuracy and repeatability coupled with high production.

...more

Pneumatic Power Press

We are offering h frame type pneumatic power press. rt power press are designed and developed through years of experience in sheet metal working machines. Rt power press are widely accepted in industries for continuous production runs, and in areas requiring accuracy and repeatability coupled with high production.

...more

Plate Bending Machine

We are offering plate bending machine. Specifications: the pinch cum puramid principle the machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll pinch type machines. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. An error in pre pinching can be corrected even after the shell is completed. It can pre-pinch and roll the plate without removing the plate from machine after first insertion. Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates. cone bending the machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. salient features top roll drive for rolling thin plates. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. Plate squaring(aligning) arrangement. Small dia. Top roll for small shell rolling (for reduced capacity).

...more

Over Crank Shearing Machine

We are one of the credible Manufacturers and Suppliers of Over Crank Shearing Machine. Designed to excellence, Over Crank Shearing Machine is efficient for shearing all kinds of materials. The design of Over Crank Shearing Machine ensures easy and stable operations. We offer Over Crank Shearing Machine in different technical specifications. Highlights Robust construction Smooth working Efficient design Longer service life Details Frame : Rigid steel frame of Shubham Shears are optimally designed to avoid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by accurate machined guide ways ensuring proper clearance and clean cut. Hold � Down System : Spring loaded mechanical hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cuts. Hold down units are provided with oversize pads to avoid impressions on sheet metal on request. Knives : Shubham Shears are provided with high quality single segment (HcHcr) Knives for longer tool life. Ease in assembling of knife reduces down-time. The knife blades are four edged. Lubrication : All bearing parts and guide surfaces are lubricated through hand-operated lubrication system. Mechanical Back Guage : This is a standard equipment provided on all Shubham Shears. Scale on the back guage gives instantaneous reading of distance between shear and back guage. Thus avoiding errors and maintenance encountered in electronic equipment. Finger Guard : Fitted in front of hold-down for operator protection without obstructing viewing. Features Foot Pedal. Fly Wheel & Gear Guard. Self Lubrication System Motor Pully A Pair of Four Edge Sher Blade Standard Front Guage Back Guage (Manual Operated) Options Motorised Back Guage. Automatic Lubrication System. Vee-Belts. Electric Motor & Starter / Control Panal Board. Squaring Guage System. Stroke Counter. Extension Squaring Arm. Hydraulic Holddown Pads (Cam-Pump). All Dimensions are in mm. Power Supply 400/440 volts, 3 Phase, 50 Cycle. As day to day improvements are contemplated for better performance of the machine. We reserve the rights to alter the specifications without prior notice. All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation.

Type : Mechanical Over Crank Shearing Machine

Application : Structural Analysis

Weight : 100-1000kg

Voltage : 110V, 220V

Automatic Grade : Automatic, Fully Automatic

Warranty : 1year

...more

Metal Sheet Straightening Machine

Motivated by the aim to deliver nothing short of the best, we have grown as a reliable supplier of Metal Sheet Straightening Machine in the market. We guarantee secured payment procedures, whether online or offline. The customers can pay us through multiple options.

Type : Metal Sheet Straightening Machine

Driven Type : Electric, Hydraulic

Warranty : 1year

Voltage : 220V, 380V, 440V

Weight : 100-1000kg, 1000-2000kg

...more

Mechanical Press Brake Machine

Based in Rajkot, we are a prominent Manufacturer and Supplier of Mechanical Press Brake. The design of Mechanical Press Brake is based on innovative engineering. Further, Mechanical Press Brake is configured with advanced technology which efficiently boosts production capacity of unit. Highlights Robust construction Smooth working Efficient design Longer service life Details Frame : Frame is of robust fabricated steel construction of rigid and interlocked design, It is strain- free and supports the ram and bed against undesired deflection under permissible loding condition. Ram and Bed : Made from steel Plates of suitable thickness, machined for straightness and parallelism of the working surfaces. Ram is guided and supported throughout the stroke by accurately machined guided ways. Drive System : Power is transmitted to the ram through two individual geardrives for uniform load distribution throughout the length. This also reduces the torsional stresses on the eccentric shaft. Electric motor used is of sufficient H.P. which reduces slowdown of flywheel and increases energy available per stroke. The gear and pinion are made out of carbon/alloy steel. Ram Adjustment : Motorised ram adjustment through a simple drive mechanism, facilitates quick bending angle adjustment. Angular ram adjustment is made simple by incorporating a spring loaded dog clutch. Clutch and Brake : All series of press brakes are provided with high-torque low-inertia friction clutch, synchronized with heavy duty mechanical brakes ensuring immediate braking of ram on releasing the pedal. Clutch operating levers are designed in such a way that minimum engaging force is required at the pedal. Features Foot Pedal and Die Block Lifting Link. Fly Wheel & Gear Guard. Self Lubrication System. Motor Pully. Stroke counter. Standard �V� Block and Punch. Motor Mounting Bracket. Options Motorised Back Guage. Automatic Lubrication System ee-Belts. Electric Motor & Starter / Control Panal Board. Squaring Guage System. Various type of Die & Punch. Foundation Bolts. All Dimensions are in mm. Power Supply 400/440 volts, 3 Phase, 50 Cycle. As day to day improvements are contemplated for better performance of the machine. We reserve the rights to alter the specifications without prior notice. All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation.

Type : Mechanical Press Brakes Machine

Weight : 100-1000kg, 1000-2000kg

Automatic Grade : Automatic, Fully Automatic

Power : 110V, 220V

Driven Type : Mechanical

Warranty : 1year

...more

leveling machine

Be it any place or time; we make on time deliveries of the goods to the customers. Positioned amidst the celebrated names of Leveling Machine, we are customers' reliable choice in this field.

Type : Hot Air Leveling Machine

Voltage : 220V, 230V, 380V

Automatic Grade : Automatic, Manual

Driven Type : Electric, Hydraulic

Warranty : 1year

Weight : 100-1000kg, 1000-2000kg

...more

HYDRAULIC PRESS 800 RON

1 Piece (MOQ)

We are main supplier of this product.

Hydraulic Press

we are offering hydraulic press. we are engaged in offering hydraulic press. the range offered by us includes hydraulic press, four pillar type hydraulic press, tie rod hydraulic press and window frame hydraulic press. the presses offered by us are manufactured in adherence with the set industry standards and norms using high-grade raw material and advanced technology. these presses offered by us are widely demanded by the clients for their high performance. range offered by us detailed below:

Brand Name : RT Power Press

...more

Decoiler Machine

Buyers can order our products in bulk, as we maintain year around availability. In addition, we have reliable transportation system to make timely delivery. Our team members help us completely to deliver exceptional range of products that is in conformance with the standards.

Driven Type : Mechanical, Electric

Automatic Grade : Semi Automatic, Manual, Automatic

Power : 3-6kw, 1-3kw

Voltage : 220V, 380V

Type : Decoiler

Weight : 100-1000kg, 1000-2000kg

...more

Decoiler

1 Piece(s) (MOQ)

We are offering you a decoiler for your cile settings. I also provide u a vertical decoiler. As per your plant settings we can provide u a decoiler.

...more

Cut to Length Line Machine

To ensure distribution of orders within undertook period, our organization has an outstanding supply chain system in place. Enlisted amidst the renowned Suppliers of Cut To Length Line Machine, we cater to varied demand of the customers in this sphere.

Type : Cut To Length Line

Application : Industrial

Weight : 1000-2000kg

Voltage : 220V, 380V

Automatic Grade : Automatic, Fully Automatic

Driven Type : Electric, Hydraulic

Warranty : 1year

...more

Coil Slitting Machine

We have carved a dignified position in the market owing to our on-time and safe delivery of the orders. Catering to the voluminous and urgent requirements of our clients from Rajkot(India); count on us to avail the same

Type : Coil Slitting Machine

Weight : 100-1000kg

Voltage : 220V, 380V

Rated Power : 3-6kw, 6-9kw

Automatic Grade : Automatic, Manual, Semi Automatic

Warranty : 1year

...more

Cnc 2d Wire Forming Machine

We specialize in manufacturing and supplying a qualitative range of wire & strip forming machines. The wire & strip forming machine ensures maximum production of wires and strips. These machines have a touch screen software to enhance productivity both in terms of quality and quantity. Our wire & strip forming machines are fully automatic and suitable for the production of all types of strips. These precisely designed and engineered machines save both power and energy and, therefore, highly demanded by clients across the nation. We offer this machine at a highly competitive price in the market.

...more

80 Ton Hydraulic Press Brake

20 Ton (MOQ)

We are offering hydraulic press brake. Press brake machine capacity 80 ton bending capacity. (length x thick 2540 x 4 mm dist. Between housing 1700 stroke length 75 stroke per minute 30 ram adjustment 75 shut height ram stroke down 220 table height 800 depth of throat 300 main moter hp 10 ram adjustment moter hp 1.5 die-space (length x width) 2540 x 200 machine diamensions (l x w x h) 2900 x 1500 x 2850 approx weight kg 5500

...more

punching press

1 Piece(s) (MOQ)

We are distinctly recognized amongst the industrial hydraulic punching press machine manufacturers. Our industrial hydraulic press machinery is widely admired for its ease of use and delivering high productivity. The industrial hydraulic press machinery, offered by us, is considered the best in class at it saves human efforts significantly. The machine does not occupy much of space at factory or workplace. These presses have unique features of dimensional accuracy, low maintenance costs, optimum performance, fine finish, and reliable operations.

...more

100 Ton Mechanical Power Press

3 Ton (MOQ)

We are offering mechanical power press machine. Capacity 100 ton stroke adjustment 13-127 depth of throat 320mm dist bed to ram 450mm length & width of bed 900x640 mm hole in bed 190 mm hole in ram 50mm crank shaft diameter 127mm fly wheel diameter 813mm stroke per minute 30 motor (siemens company) 10 hp weight approx in kgs. 5400

...more

Strip Forming Machine

we are the manufactures of power products our from last 5 years. this strip forming machine to meet ever drawing requirements of the clients

...more

cross shaft power press machine

We are the main supplier of this product.

Opening Hours