Mechanical Shearing Machine

Get Price Quote

Hot Billet Shearing Machine

Get Price Quote

We offer Hot Billet Shearing Machine. This machine special design for CONTINOUS CASTING MACHINE in steel mill. Its used for cut to length hot billet shearing. Horizontal construction with travelling cylinder for accurate shearing.

Best Deals from Shearing Machines

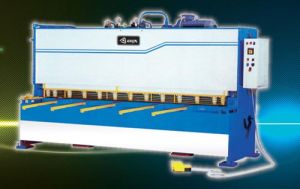

Hydraulic Shearing Machine

Get Price Quote

1 Piece (MOQ)

We are offering hydraulic shearing machine, "anox" hydraulic shearing machine size 2000 to 6000 mm. Hydraulic Shearing Supplied by us serves the various Industries including Agricultural, Control Panel, Bus Body, Hardware Products, etc......

Mechanical Over Crank Shearing Machine

Get Price Quote

Rigid Steel Frame of Kishan shears are optimally designed to avoid weak sections and is of interlocked design. The Ram is guided throughout its length by accurate machined guide ways ensuing proper clearance and clean out.

Mechanical Shearing Machine

200,000 - 1,000,000 Per Piece

1 Piece(s) (MOQ)

Extra Rigid Frame Structure Press Brake Machine. All Parts Of Machine Are Accurate &precision Machining Before Machine Fitting.All Gears & Shafts Made From Carbon Steel.

Treadle Guillotine Shearing Machine

45,000 - 145,000 Per piece

1 piece (MOQ)

The Everest Cast Iron Body Treadle Guillotine Shearing Machine with best workmanship, robust and streamline construction is developed and designed after maker's extensive experience in manufacturing and sales of such machines. The machine is having wide application in industries like Tin Containers Barrels Drum P. P. Caps Calendar Rims Electricals is having with application in industries like Fabrication Control Panels & Boards Brass Alluminium Furnitures M.S. & Steel Cutting Block Makers, etc... Silent features Rigid and streamline construction ensures vibration-free and fatigue less function of the machine. Upper Beam/Ram is moving in C. I. Guide ways with precision bearing surface and having adjustment for compensating wear and tear. Adjustable front & back gauge with Through slots which facilitates adjustment of different widths of cuts and avoids any sorts of waves and twisting of sheets while cutting. Adjustment bolts allow setting of blades to cut various thickness. Machines are fitted with HCHCR quality Four Edge Shearing Blade to avail maximum use of blades The extra heavy Treadle with proper weight is spring loaded and very well designed for operator's convenience which takes minimum pressure while cutting. The Springs fitted are of proper compression and strength. All lubrication points are provided with lubrication cups at required places to ensure smooth, trouble free and long life of machine. The Setting bolts are provided for lower-fixed blade to adjust vertically when height of blade is reduced after resharpening.

Power Shearing Machine

500,000 Per Piece

1 Piece (MOQ)

Hand Notcher

18,000 Per Piece

1 Piece(s) (MOQ)

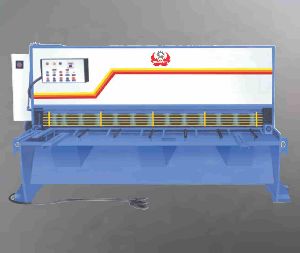

Hydraulic Shearing Machine

Get Price Quote

Hydraulic Shearing Machine

400,000 Per Piece

1 Piece(s) (MOQ)

We are a reputed shearing machines manufacturer in Rajkot and can assure you that there is never compromise on the quality standards of the offered product at present and feature. At Exponus Tradelink Private Limited, we are engaged in presenting an exclusive range of hydraulic shearing machines for our buyers. Hydraulic shearing machines are extensively used for cutting bars, large sheets, and plates of metallic and non-metallic materials into various shapes. These machines are manufactured for smooth and precise cutting. Hydraulic shearing machines are widely used in automobile, food processing, printing, engineering, plastic manufacturing, construction, electrical, woodworking, and many other industrial segments. We are also a responsible automatic hydraulic shearing machines supplier in the market. The offered machines are very compact, safe and durable tools. These tools are highly acknowledged for high operational efficiency, better stability, vibration-free functioning, rugged design, higher output, and longer service life. Our hydraulic shearing machine has its own hold on the market also and has a very good reputation. With the support of proficient professionals, we produce these machines by employing the latest technology in strict compliance with the international quality standards. Thus, these machines have got great positive feedback from our customers. As a famed hydraulic shearing machines exporter, we are successfully involved in providing many models with varied specifications. At Exponus Tradelink Private Limited, we make sure that the offered product line satisfies the functional needs of our clientele. Clients are free to share their specific requirements, we assure to work around. Further, we ensure that the ordered products reach their destination in the promised timeline.

Under Crank Shearing Machine

Get Price Quote

Our zeal to achieve excellence enables us to design and develop efficient Under Crank Shearing Machine. Our Under Crank Shearing Machine is quality tested and promises remarkable workability at low operational cost. Configured with advanced technology, Under Crank Shearing Machine boosts productivity of shearing in any heavy metal industry. Highlights Robust construction Smooth working Efficient design Longer service life Details Frame : Rigid steel frame of Shubham Shears are optimally designed to avoid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by accurate machined guide ways ensuring proper clearance and clean cut. Hold � Down System : Spring loaded mechanical hold down pads hold the sheet security, to avoid slipping and bowing resulting in clean square cuts. Hold down units are provided with oversize pads to avoid impressions on sheet metal on request. Knives : Shubham Shears are provided with high quality single segment (HcHcr) Knives for longer tool life. Ease in assembling of knife reduces down-time. The knife blades are four edged. Lubrication : All bearing parts and guide surfaces are lubricated through hand-operated lubrication system. Mechanical Back Guage : This is a standard equipment provided on all Shubham Shears. Scale on the back guage gives instantaneous reading of distance between shear and back guage. Thus avoiding errors and maintenance encountered in electronic equipment. Finger Guard : Fitted in front of hold-down for operator protection without obstructing viewing. Features Foot Pedal. Fly Wheel & Gear Guard. Self Lubrication System Motor Pully A Pair of Four Edge Sher Blade Standard Front Guage Back Guage (Manual Operated) Options Motorised Back Guage. Automatic Lubrication System. Vee-Belts. Electric Motor & Starter / Control Panal Board. Squaring Guage System. Stroke Counter. Extension Squaring Arm. Hydraulic Holddown Pads (Cam-Pump). All Dimensions are in mm. Power Supply 400/440 volts, 3 Phase, 50 Cycle. As day to day improvements are contemplated for better performance of the machine. We reserve the rights to alter the specifications without prior notice. All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation

Hydraulic Sheet Shearing Machine

Get Price Quote

Over Crank Shearing Machine

750,000 Per unit

1 unit (MOQ)

mechanical shear

900,000 Per Piece

Hydraulic Shearing and Press Brake Machine

Get Price Quote

We are one of the most acknowledged Manufacturers and Suppliers of highly efficient Hydraulic Shearing and Press Brake Machine incorporated with the latest technologies. Our Hydraulic Shearing and Press Brake Machine is highly in demand by the clients owing to its sturdy construction, trouble-free operation, low maintenance and longer functional life. Hydraulic Shearing and Press Brake Machine that we offer is widely in demand by the clients for carrying out different industrial tasks.

Gullotine Shearing Machine

Get Price Quote

We are offering gullotine shearing machine, mechanical, pnumatic, hydraulic, nc and cnc gullotine shearing.

Hydraulic Shearing Machine

Get Price Quote

Standard Features: Moving beam synchronized by differential cylinders. Hardened rollers guide beam for constant blade gap. Rank angle adjustable to suit thickness and material. Blade gap adjustable with levers for clean cuts. Sheets clamped hydraulically before cut starts. Shearing-clampin forces adjustable to suit job. Both blades premium HCHCr, four usable edges. Cutting length and position adjustable for shorter job. Beam returns on releasing foot switch for smaller cuts. Cutting area illuminated for clear view of blades. first two hold-downs spaced closer at both ends. Squaring arm 1000mm at left with hardened lines. Squaring arm 600mm at right helps distribute wear. Front gauging with stops, scale on squaring arm. Hardened rods, recessed table for easy sheet feeding. Sheet supports 1000mm long help support long plates. Ramp on rear slides out cut sheets outside shear area. Back gauge moves away trapping of cut sheets. Foot switch movable for operation from safe position. Finger Safety guard with clear view of lighted cutting area. Dependable global of hydraulics, electrical. Efficient compact power pack with minimal piping. Electrical neatly wired-labelled for trouble shooting. Optional Accessories: Sheet front feeding system. NC back gauge with ball screw. Hydraulic rear sheet support. Automatic control shearing. Sheet rear stacking system.

Mechanical Shearing Machines

Get Price Quote

1 Piece (MOQ)

* s.k. Brand under crank mechanical shearing machine *s.k. Brand under crank mechanical shearing machine capacity: 2 m.m. To 4 m.m. Length cap. 1270mm to 3125mm * s.k. Over crank mechanical shearing machine. *s.k. Brand over crank mechanical shearing machine capacity :6 m.m. To 10 m.m. Length cap. 1270mm to 3125mm frame: rigid steel frame of sk shears are optimally designed to avoid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by hardened & ground guide ways ensuring proper clearance and clean cut. hold-down system: spring loaded mechanical hold-down pads hold the sheets securely to avoid slipping and bowing result in clean square cut. Hold down units are provided with oversize pads to avoid impression on sheet metal. Blade : sk shear are provided with four edge, single & segmentally high carbon, chromium steel blades suitable for m.s. &.s.s. Cutting and extra long life. Lubrication : all bearing parts and guide surfaced are lubricated through centralize hand-operated lubrication system. Mechanical back gauge : this is a standard equipment provided on all sk shears. Scale on the back gauge gives instantaneous reading of distance between shear and gauge, thus avoiding errors and maintenance encountered in electronic equipment. Finger gauge : fitted in front of hold-down for operator safety without obstructing viewing. Standard equipment : electrical system consisting of motor & control panel of starter, gear and wheel guard, v-belts, hand operated back gauge, manual lubrication system, t-slot gauge, front scale gauge, instruction manual. Optional equipment : hydraulic hold-down system, automatic lubrication system, ball roller or ball transfer, foundation bolts, extension squaring arm. Note: electricals and blades are not under warranty.

Under Crank Shearing Machine

Get Price Quote

The Frame is fabricated from steel plates of is 226 Grade. The frame is designed to take heavy loads. The interlocked design put the direct support to frame. Thus frame is strain free and eliminates welds at load supports. Thus the Accuracy of The Machine is never disturbed. Steel fabricated, box type table is heavily ribbed for strength and is stress relieved its machined seat provides true and firm support to the bottom blade. It is adjustably for setting the blade clearance. The top surface of the table is provided with T slots for adjusting the front gurge.

Mechanical Under Crank shearing Machine

Get Price Quote

SHAILESH shearing machines have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability.Rigid steel frame of SHAILESH shears are optimally designed to avid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by hardened and ground guide ways ensuring proper clearance and clean cut.

Hydraulic Plate Shearing Machine

Get Price Quote

Under Crank Shearing Machine

Get Price Quote

Searing Machine

Get Price Quote

We guarantee to make on time delivery, as we have an extensively spread network of logistic facility providers and dealers. To stock our product for wholesale distribution, we have a state-of-the-art storage facility equipped with the latest inventory control management system. It enables us to meet bulk or retail requirements with ease. Product Details : Machine Type - Lathe Machine,Milling Machine,Drilling Machine,Boring Machine Operation Mode - Semi Automatic Service Location - Any Where in India Approx Price : Rs 3,000 / Piece

Hydraulic Shearing Machine

Get Price Quote

Manufacturer of milestone brand high quality hydraulic shearing machine, Press Brake, Shearing Machine and Plate Bending Machine,plate rolling machine,cutting machine,cuff & collar cutting press and all types of Workshop Machinery & Sheet Metal forming machinery with reliable prize.

Shearing Machine

6 Per Piece

Hydraulic Shearing Machine

Get Price Quote

We are manufacturer, exporter and supplier of the best variety of hydraulic shears, portable hydraulic shears, hydraulic shearing machines, shearing machines, hydraulic metal shears, hydraulic shears portable which find great relevance in almost all industries. Manufactured by our efficient engineers and technicians these are easier to use and have all the essential features which make these worthy to be purchased. Their features include:

Shearing Machines

Get Price Quote

Approx Price: Rs 5 Lakh Unit Product Details: Operation Mode Automatic, Semi-Automatic, Manual Max Shear Thickness(mm) 1 to 2, 2 to 3, 3 to 4, 4 to 5, 5 to 6 Cutting Material Copper, Stainless Steel, Iron, Aluminum, Carbon Steel Max Shear Width 0-500 mm, 500-1000 mm, 1000-2000 mm, 2000-3000 mm, 3000-4000 mm Strokes per min 3.0, 5.0, 8.0, 10.0, 12.0, 14.0 Shearing are available in capacities ( size ) of 4 feet 5 6 8 10 12 feet & 13 feet length thickness of machine is 0. 100 mm up to 16 mm capacity, rolling key clutch, spring loaded mechanical hold down pads,with all standard accessories.

Shearing Machine

Get Price Quote

Power Shearing Machine

Get Price Quote

Power Shearing Machine, Treadle Shearing Machine, Press Brakes

Shaping Machine

Get Price Quote

Shaping Machine, Hand Operated Hydraulic Press