Vibrating Screen

Get Price Quote

Vibratory feeder is used to transfer the various size materials or granular materials from hopper to receiving device uniformly, continuously and periodically in the production flow and to feed materials into the Belt Conveyor or Crusher continuously and uniformly. The vibrating feeder is widely used to match the crushing and sieving equipments in many industries including metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc.

Rectangular Vibrating Screen

Get Price Quote

Since our inception, we are instrumental in offering a premium quality array of Rectangular Screen. Offered rectangular screen is meticulously checked under the direction of our quality experts against different quality parameters, to provide defect free assortment to our customers. Our practiced professionals design this rectangular screen with the use of ultra modern technology and quality approved components. Additionally, this rectangular screen is widely demanded in market.

Best Deals from Vibrating Screen

Motorized Vibrating Screen Machine

850,000 Per Piece

Single/Double - Deck Vibrating Screens

Get Price Quote

Single/Double Deck Vibrating Screening Machines are designed for screening of powders. These machines are simple and robust in construction. Available in Screen size of 1500 x 600mm,1800mm x 800mm, 2500mm x 800mm. Special sizes as per customer specifications are also manufactured.The Vibrating screens are also available with magnetic system to remove Fine iron. Contamination from products like Chemicals, Pharmaceutical and Food products etc.

Vibro Screens

Get Price Quote

Veer Vibro Screens are designed to perform effective size based separation in coarse as well as fine sizes. These Screens are designed on the principle of Rotating Motion and are one of the most versatile and universally adaptable machines working across spectrum of industries. Vibro Screens can carry out various duties like; Screening of any powder or granules Sifting and Grading or classification removal of oversize/ undersize/ chips/ dust removal from powder/ granules, solid liquid separation/ filtration/ grit removal from slurry, syrup or oils, fiber / husk recovery from liquid stream. Vibro Screens are used in Industries like Agro Agro Processing Ceramic Chemical China Clay Dehydrated Food Dyes and Pigments Ferro Alloys PVC Foundry Plastics Engineering Food & baverages Mines and Mineral Metal Powder Processing Petrochemical Paper Rotomolding and many more. Construction: Vibro Screens are designed on the principle of gyratory motion generated by double eccentric weight mounted on two ends of the shaft of vertically mounted specially designed vibratory motor. The screening assembly consisting of one or more set of Deck/screens is mounted on a set of annularly located springs, effectively isolating the base from vibrating assembly. The double weight moving with the shafts and located at relative angular position produces three dimensional vibrations which in turn cause the material falling on the screen mesh move at a specific speed in straight to spiral direction giving controlled and effective screening. Due to the adjustability of weight and the relative angle between them it is possible to make the material move on the screen in desired path to achieve the desired retention time for effective screening before the material gets discharged from the outlet spout. During this process the particles smaller than the mesh aperture fall through the mesh and the oversize material gets discharged from the outlet spout. This process is repeated on the next mesh in case of multi deck screening. Features & Benefits Continuous Feed - Continuous Discharge Low Power Consumption (Max. 3 Hp) Reduced Environmental Hazards No Screen Choking / Clogging Savings On Manpower Cost Reduction In Material Loss Better Pollution Control Better Process Control Continuous Screening Better Product Quality Compact And Elegant Dust Free Screening Low Maintenance Easy Openability Low Capital Cost Modular Design Flexible Layout

Vibro Screen

Get Price Quote

We are offering vibro screen. One of the leading company of vibro screen from india.

Rotary Screen

Get Price Quote

Rotary Screen, Portable Jaw Crusher, Impact Hammer Mill, Chemical Pulverizer

Rectangular Vibrating Screens

Get Price Quote

Rectangular vibrating screens is available in single double and multi stage screen we made for heavy industrial supply for any vibrating screener, screen design will be a key factor in unit performance and maintenance. Screen cloth that is highly pre-tensioned across a frame and securely bonded provides the best screening surface with the longest life. Cleaning kits incorporated into the screen design provide dynamic anti-blinding action when needed. Additionally, designs that enable screen changes without tools minimize maintenance costs and downtime. Vibrating screens play an important role in stone, ceramic, glass, plastic, minerals salt etc. Industries manufacturing operations. Careful analysis of all factors before ordering will result in smooth field startups and optimal production performance.

Vibrating Screen

Get Price Quote

We are well known supplying company of Vibrating Screen.

Rectangular Vibrating Screen

Get Price Quote

Screen design is a key factor to ensure optimum performance and maintenance for any vibrating screener. Thus, we offer a high quality Rectangular Vibrating Screen. Extremely pre-tensioned across a frame, the Screen Cloth provides the best screening surface and long life. The Rectangular Vibrating Screen features cleaning kits to provide dynamic anti-blinding action, whenever needed. Rectangular Screen changes can be done without using tools. This minimizes maintenance costs and downtime. Available In : Single, Double, and Multi Stage Screen Used In Processing/Manufacturing Of StoneCeramicGlassPlasticMineralsSalt

nickel perforated rotary screens

Get Price Quote

nickel perforated rotary screens

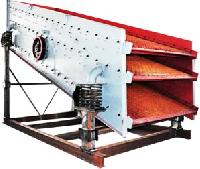

Vibrating Screen

Get Price Quote

Specification: crushtech, Vibrating Screen are Mainly Composed of Screen Box, Screen Mesh, Vibrator, Heavy Spring with Heavy Base, Etc. the Vibrating Screen Can Be Driven By the Vibrating Motor or Belt to Rotate and Produce Centrifugal Inertial Force to Make the Screen Box Vibrate. working Principle: vibrating Screens Work On Circular Motion. the Vibrating Screens are Mainly Used in Coal Dressing, Metallurgy, Mine, Power Station, Water Conservancy Project, Building Industry, Light Industry, Spice Industry, Chemical Industry & Etc They are Efficient Screening Machines for the Classification of Bulk Material such as Coal, Minerals, Coke Etc There are Heavy Duty Type of Classification of Large Size Materials, While the Light Duty Type is for the Middle and Small Size Materials. vibrating Screen Moves Round. It Has Multi-layers and is of High Efficiency. the Eccentric Shaft Vibration Exciter and Partial Block Help to Adjust Amplitude. the Material Drops Down Along the Long Line. advantage: our Vibrating Screen Has Many Different Features like Stable Vibration, Reliable Work, Long Life; Adjustable Exciting Force, Casual Adjustment and Control of Screening Quantity, Convenient and Stable Adjustment; Using Vibration Generator as Exciting Source, Low Noise, Low Power Consumption, Good Adjustment Performance, Simple Structure, Reliable Operation, Easy Adjustment and Assembly, Light, Small, Convenient Maintenance and Dust Prevention When in Closed Body. applications: screening & Cleaning for Dry Chemical, Minerals, Spices, Stones & Etc.

Vibrating Screens

Get Price Quote

Vertical Shaft Kiln, sponge iron feeding system, solid waste equipment

Vibrating Screen

Get Price Quote

prong magnets, Magnetic Rod