Vibratory Metal Polishing Finishing Machine

Get Price Quote

1 Piece (MOQ)

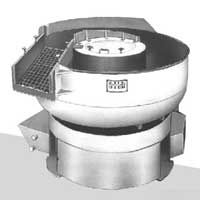

Auto Separation Vibratory Finishing Machine

80,000 - 100,000 Per piece

1 Piece (MOQ)

Auto separation Vibratory Finishing Machine are designed with in built media & parts separation with flapper, the unload plate can float on the media at work, and while the separating work part from media, the unload dam flapper sink, parts can be separated easily with simple operation.Advantages Deburring Polishing Fine Finishing Surface Smoothness Mirror Polishing Descaling Edge Rediusing Derusting Features & benefits 85-100 % separation can be achieved Automatic separation of part & media Can be added in continues production system Rugged one piece welding structure Bowl with 80 ± 3 Shore PU lining Powered by heavy duty vibratory motors Model : “NAKU” vibro Finishing Machine available in Rubber & PU Lining. Machine motors are manufacture by us. Motor power supply is 3 Ph. 440 V 50 Hz. Model Machine Capacity Machine Dia. (M.M.) Motor HP NVF 60 60 Lit. 880 1 NVF 90 90 Lit. 950 1 NVF 120 120 Lit. 1020 2 NVF 200 200 Lit. 1150 2 NVF 300 300 Lit. 1300 3 NVF 400 400 Lit. 1450 5 We are also providing Consumable items of vibro finishing machine like Ceramic Media, Plastic Media, Steel Media, Finishing Compound, Vibratory Motor, Corn Cobb. Additional Information: Delivery Time: 4 to 5 Weeks

Best Deals from Vibratory Finishing Machine

Vibratory Finishing Machine

Get Price Quote

We bring forth superior quality Vibratory Finishing Machine, which is manufactured using latest technology. Our range of Vibratory Finishing Machines finds application in various engineering industries due to its high performance and longer working life. We are counted as one of the leading Manufacturers and Suppliers of Vibratory Finishing Machine based in India.

Vibratory Surface Finishing Machine

Get Price Quote

5 Piece (MOQ)

Vibratory Finishing Machine

Get Price Quote

Bhalani industries Vibratory Finishing Machine is a bowl type finishing machine, it’s also known as vibro finishing machine. The machine bowl is loaded with suitable finishing media and the components be processed. The bowl is coated with rubber or PU lining. Vibratory finishing is a surface preparation process in which the work piece and finish media are subjected to a controlled gyratory vibration. The interaction between the finishing media and the work piece results in deburring, descaling, rounding of corners and polishing of the work piece. Compared to other simpler processes this method completes the deburring process faster. Vibro finishing machine is driven by powerful vibratory motor causing intense rubbing and trouble-free output. This machine also known as Vibratory Finishing system, vibratory deburring machine, vibratory polishing machine, Vibro finishing machine, Vibratory Finishing system, Mass Finishing Machine, vibratory tumbler manufacturers, Bowl Finishing Machine, Vibratory Surface Finishing Machines.

Vibratory Finishing Machine

Get Price Quote

Vibratory finishing machines are mass finishing machines used for industrial parts deburring, descaling, edge radiusing, polishing, mirror finishing and surface improvement on metal and plastic components. We provide standard and complete customised vibratory finishing solution based on customers finishing requirements. principle :- vibratory machines comprise a metallic bowl which is lined inside with polyurethane (pu), loaded with media & compounds. In the center of the bowl special designed heavy duty vibratory motor is mounted to generate spiral motion. This creates a continuous relative motion between media & compound which resulting into required components finishing by enabling material erosion. These machines can further be customised and various levels of automation can be incorporated to give you a completely integrated automated mass finishing system. Special compounds can also be added to achieve better & faster results. advantages: suitable for very small to large parts in batch or continuous operation. Easy in-process inspection. Advance mechanism for integral separation of component, media, chemical & contamination. Cascade and circular action make best use of media and proper parts mixing. Best suited economical solution for general purpose work, heavy deburring, continuous processing and continuous inspection. Full automation capability including component handling, media & chemical dosing, spray cleaning, separation, conveyorising, drying, etc.

Vibratory Finishing Machine

28,000 Per Piece

1 Piece(s) (MOQ)

Bowl Vibratory Finishing Machine

65,000 Per Piece

Vibrating Tumbler

399 Per Piece

1 Piece (MOQ)

Features: High-quality fiber body Linked polyethylene ensures any polishing media can be used to achieve optimum processing results Suitable for a small/medium jewelry unit Special rubber mold spring to provide durability One year motor guarantee Low noise & compact size Many types of media can be used.Four types of polishing media used are: Stainless steel media - 7 Kg Ceramic media - 3 Kg Plastic media - 3 Kg Walnut media - 2 Kg

Vibrotory Finishing System

Get Price Quote

Vibratory Finishing Machine are used for Deburring, Polishing De-scaling, and Antique Finishing etc on any types of metal, it is generally preferred when higher vibration is required and for medium to big size parts or heavy parts.

Vibratory Finishing Machine

Get Price Quote

Our company is among the most trusted companies in the manufacture, supply and export of Vibro equipment. These equipment are well equipped by high experienced professional expert and are manufactured by supreme quality material. These equipment have no vibration transmission and are highly used in Automobiles Industries. Last but not the least these are best quality equipment and follow unique working principals. Features: Reasonable price International standard Widely used

Vibratory Deburring Finishing Machine

Get Price Quote

Vibratory Finishing Machines

55,000 Per Number

1 Number (MOQ)

Tub Vibro Finishing

Get Price Quote

Tub Vibro Finishing This results in efficient processing of components. Vibration can be adjusted with eccentric weights and systems can be batch type, continuous or customized as per needs. Machine can be customized to suit parts, Can handle small to very large and very long parts.

Automatic Vibratory Finishing Machine

110,000 Per Units

Vibratory Finishing Machines

Get Price Quote

we offer Vibratory Finishing Machines. Vibratory Finishing is quite different from hand polishing, buffing, filing, belting, ets. as you are not overly depended on the skill of the operator. Instead, it is a mass finishing process technique, lending itself to batch processing of components and uniformity for the entire lot. Parts are typically bulk loaded for a long batch process or continuously fed into a vibratory machine. Media of various compositions and sizes are used in the bowl alongwith different type of soap based chemicals compounds.

Vibratory

Get Price Quote

Vibratory Motor is manufactured for flexible individual application to suit all working environment. These motors are used in various material handling equipments, such as vibrating screens, conveyors and feeders. We are well recognized manufacturer and supplier of vibratory motors, accurately engineered with finest grade material. We offer high quality unbalanced vibratory motors for so many industrial applications. Our vibratory motors find its applications in mining, pharmaceutical, chemical, fertilizer and food processing industries. Though, we cater numerous industrial fragments with our vibratory motors, but our main focal point is food processing industry. It is extensively used in seed processing procedure. Vibrators are used in every step of seed processing and other food processing processes. Vibrators are used to convey, clean, screen, empty, test and distribute the material or product. It is specially designed to use with vibrating feeders, vibrating tables and screens. It is also used with storage tower and silo. We offer optimum quality vibratory motors for circular vibrations and directional vibrations.

Vibratory Finishing Machines

180,000 Per Piece

1 Piece (MOQ)

Vibratory Finishing Machine

Get Price Quote

Vibratory Finishing Machine

Get Price Quote

Vibratory Finishing Machine, offered by us, is ideal for process like de-scaling, de-burring, polishing, surface improvement, edge reducing as well as pre-plating finishing all types of components that includes fully machined parts in metals & plastics. Our Vibratory Finishing Machine is widely applied to instruments, metal parts, apparatus, standard parts, sewing machines, auto parts, bearings, non-ferrous metal products, etc. Working Principle The vibratory finishing machine for metal working has a ring chamber to hold abrasives and work pieces. When the machine is working, it makes three-d high frequency vibration. The grinding stones and the work pieces are rolling spirally forward and they are grinding each other during the rolling. This makes the work pieces de-burred, chamfered, polished and clean, to replace the traditional cloth-wheel polishing, the vibratory finishing machine for metal working can save a lot of spending on manpower, and lower the cost of production. It can also be matched up with mass production, improve and stabilize the quality of the products. Applications Mainly applied to metal parts, standard parts, apparatus, instruments, bicycles, sewing machines, hydraulic parts, bearings, auto parts, plastics, ceramics, non-ferrous metal products and parts industry de burring parts to rust, polishing rough, medium polished, fine polishing, bright polishing, especially for special-shaped part of the surface finishing are superior to specific functions, as it after finishing the parts.

Vibratory Finishing Machine

Get Price Quote

100 Piece (MOQ)

Automatic Vibratory Finishing Machines

50,000 Per Piece

Vibratory Finishing Machines

Get Price Quote

We are offering vibratory finishing machines. Model number : cm series - the manual machines description : vibratory finishing machines use the principle of centrifugal force to cause vibrations to the work bowl thereby processing the components to the desired finish. The equipment comprises of a work bowl mounted on a rigid base frame. ceramed’s vibro finishing machine uses a powerful imported vibratory motor, made of special grade casting, and heavy duty spherical roller bearings. Springs are provided between the work bowl and base frame. during operation, a mass of components along with a suitable ceramic media and chemical compound is introduced into the work bowl, the whole mixture rotates inside the bowl in a spiral and rotary motion causing the ceramic media to rub against the components continuously thus imparting the desired finish to the components.

Vibratory Finishing Machine

200,000 Per unit

Vibratory Finishing Machine

Get Price Quote

Vibro finishing process involves rubbing of parts to be finished with suitable media ( ceramic, plastic, steel, etc) in presence of finishing compound for pre-determined time. VIBRO-FIN vibratory finishing machine has a bowl that holds parts, media, water & finishing compound. The special vibratory motor mounted at C.G. of the system generates intense spiral motion of parts & media in the bowl. The relative motion between parts & media results in deburring, descaling, polishing etc. VIBRO-FIN vibratory finishing machine has different options for separation of parts from media. The bowl has hot cast polyurethane lining or natural rubber lining, drain for discharge of used compound & water. VIBRO-FIN vibratory finishing machine is available is wide range of capacities from 25 lits to 2500 lits.

Vibratory Finishing Machine

Get Price Quote

we are offering vibratory finishing machine. we are one of the established names of the industry engaged in supplying a qualitative range of vibratory finishing machine. customers can avail these machines from us in variegated sizes and specifications as per their specific requirements. with the aid of our dedicated quality controllers, we ensure that only defect-free components are dispatched to the clients' end. used for: de-burring polishing de-scaling surface improvement general purpose work continuous processing inspection features: efficient removal of process fluid for best surface finish all internal welds ground smooth bowls shot blasted before and after polyurethane lining for painting anti rotation motor locking plate provided additional features: complete polyurethane lined bowl including separation area complete polyurethane dam flap to avoid metal contact instead of metal flap polyurethane corrosion resistant paint for longer life in acidic /alkaline environments accident proof media outlet design for total safety benefits: economical full automation capability better media/parts mixing owing to its cascade and circular action vibratory bowl with automatic separation specifications: model processing volume in litre motor power (hp) bowl o.d.(m.m) bowl chamber width(m.m) se-75 75 1.0 850 220 se-150 150 2.0 1050 270 se-200 200 2.5 1150 300 se-300 300 3.0 1350 350 se-600 600 7.5 1500 400

Vibratory Finishing Machine

Get Price Quote

Vibratory Finishing Machine, Beveling Machine, Disc Polishing Machine

Vibratory Finishing Machines

Get Price Quote

Vibratory Finishing Machines

Vibratory Finishing Machines

Get Price Quote

Vibratory Finishing Machines, Shot Blasting Machines, Sand Blasting Machine

Vibratory Finishing Machine

Get Price Quote

Vibratory Finishing Machine, centrifugal finishing systems, peening machines