vacuum cooker

The cooker is suitable for production of hard boiled candy, toffee and caramel varieties. Batch cooker comprises of two main parts, upper one is the stainless steel pan with steam jacket for cooking and lower one is the tilting pan of copper or stainless steel for moisture removal.

...more

vaccum cooker

UNIVERSAL COOKER WITHOUT VACUUM

As vacuumisation is not necessary for cooking of toffee mass, this toffee cooker is designed without vacuum. The cooker is suitable for production of various types of toffees. The cooking pan is made of steam jacketed stainless steel. The raw materials are loaded in pan through manhole and cooked by steam which passes through steam jacket at 8 to 10 bar pressure. The cooked mass will be discharge on cooling plate. The Cooker is suitable production of various types of toffees.

...more

Universal Cooker with Vacuum

The cooker is suitable for production of hard boiled candy, toffee and caramel varieties. Batch Cooker comprise of two main parts, upper one is the stainless steel pan with steam jacket for cooking and lower one is the tilting pan of copper or stainless steel for moisture removal. Raw material is loaded through manhole at upper vessel and cooked by steam which passes through jacket at 8 to 10 bar pressure. The cooked mass will be discharged in lower pan. Vacuumised lower vessel removes the moisture contents. The mass is discharged on cooling plate by rotating and tilting system of the lower vessel.

...more

universal cooker

The cooker is suitable for production of hard boiled candy, toffee and caramel varieties. Batch cooker comprises of two main parts, upper one is the stainless steel pan with steam jacket for cooking and lower one is the tilting pan of copper or stainless steel for moisture removal. Raw material is loaded through manhole at upper vessel and cooked by steam, which passes through jacket at 8 to 10 bar pressure. The cooked mass will be discharged in lower pan. Vacuumised lower vessel removes the moisture contents. The mass is discharged on cooling plate by rotating and tilting system of the lower vessel.

...more

two way water circulating cooling plate

toffee plant

toffee cutting machine

Toffee rope from rope sizer machine is further proceeded into Toffee Cut & Wrap Machine where it is passed through sizing wheel design as per required size of toffee to get final rope size. Then after it is cut by scissors or rotating knife according to length of toffee & then gripped in the format with paper & packed in twist form by twisting of nylon twister.

...more

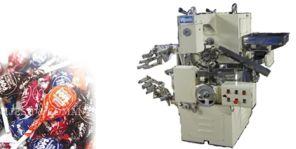

Toffee Cut & Wrap Machine

Toffee rope from rope sizer machine is further proceeded into Toffee Cut & Wrap Machine where it is passed through sizing wheel design as per required size of toffee to get final rope size. Then after it is cut by scissors or rotating knife according to length of toffee & then gripped in the format with paper & packed in twist form by twisting of nylon twister.

...more

TOFFEE CUT

TOFFEE CUT & WRAP MACHINE:Toffee rope from rope sizer machine is further proceeded into Toffee Cut & Wrap Machine where it is passed through sizing wheel design as per required size of toffee to get final rope size. Then after it is cut by scissors or rotating knife according to length of toffee & then gripped in the format with paper & packed in twist form by twisting of nylon twister.

...more

toffee cooker

this toffee cooker is designed without vacuum. The cooker is suitable for production of various types of toffees. The cooking pan is made of steam jacketed stainless steel. The raw materials are loaded in pan through manhole and cooked by steam which passes through steam jacket at 8 to 10 bar pressure. The cooked mass will be discharge on cooling plate. The Cooker is suitable production of various types of toffees.

...more

Tablet Forming Machine

The machine mainly consist one set of sizing wheels & tablet forming die. The rope from rope sizer machine enters in this sizing wheel and then into the tablet forming die to get the required shape of Candy as per die. to get required shape of Candy as per die. It is suitable for forming seamless sweets with high depth and thickness. The new version of Tablet Forming Machine (Plast-o-Plast) is designed with spring type die with bigger & robust punches.

...more

rope sizer

The Toffee Candy thin rope from Batch Roller further proceeds into Rope Sizer to form exact size rope as per Toffee Candy size. Rope size machine consists of semi round grooved and knurled rope wheel sets. One set is provided vertically and other are horizontal. To form exact size of rope for Toffee Candy size, the thin Toffee Candy rope passes through decreasing rope wheel set and forms exact size of rope required.

Capacity : 10 to 50 mtr. / min

...more

Robust Cooling Conveyor

This robust conveyor is similar to the regular cooling conveyor, as it has three conveyor belts to provide perfect cooling to the sweets. The speed of the first belt which is narrowest is fast and the remaining two belts which are broad are slow. The first belt is coupled to drive of sweet former, so that it can maintain its speed with machine. The first belt carries the sweets released from the high speed forming machine. Sweets from the first belt are uniformly spread onto the second belt with the help of a sprinkler. To retain the shape and size of the sweets it is very important to spread them uniformly and this is taken care by the sprinkler. With the help of guiding steel plate, sweets are passed onto the third belt. In this conveyor we have provided two input of air supply from blower. The cooling is provided by the air which is circulated through nozzles on the top for first belt. And for second & third belt side nozzles are provided for perfect cooling.

...more

pulling machine

Toffee mass from Cooling Plate is loaded into the Pulling Machine for better textures. It makes toffee mass smooth and soft. The sugar Pulling Machine can be used for all types of hard & soft sugar confectionary.

Capacity : 25-50 Kgs. / Batch

...more

ONE SIDE TWIST CANDY WRAPPING MACHINE

The machine uses all commercial packaging materials, outer wrapper such as cellophane and P.V.C, inner wrapper such as waxed paper and paper foil. The machine is fully automatic including No-Paper mechanism. The sugar boiled sweets are charged in to the S.S. Hopper from where it is released on to the rotary format by an automatically controlled vibrator. The paper flows from the paper feed station, cut to appropriate length & the sweet is lifted along with folded wrapper in to the twisting turret. The sweets are held in position by the rubber gripper. On one side fold wrapping is done by folder arm & on other side twist wrapping is done by twisting fingers and further it is collected from delivery chute.

...more

Lollipop Double Twist Wrapping Machine

This machine is used for packaging Ball Lollipops in Double Twist style. The lolipop may be stamped or molded with or without center filling (Pasty or firm center or up to about 15%). The machine uses all commercial packaging materials, outer wrapper such as cellophane and P.V.C, inner wrapper such as waxed paper and paper foil. The machine is fully automatic including No-Paper mechanism.

...more

high speed batch stirrer

HI-SPEED TOFFEE MACHINE

The High Speed Toffee machine is used to forming, cutting and wrapping in double twist wrap or fold wrap products such as, toffees, chewy sweets, chewing gum and bubble-gum products. The High Speed Toffee Machine is equipped with a rope feeding unit to produce products in various shapes like round, square, rectangular shapes.

...more

FLAVOUR MIXER

The high quality flavour mixer is used to mix different flavors, colors and acids into the mass of boiled sugar; it prevents evaporation and ensures to obtain fully homogeneous product. In Flavour mixing machine during the planetary movement, Mixing is carried out by two Teflon coated arms that operate on a sloping axis and cross each other. In the mixer bowl the sugar mass is poured from the cooker. With the use of trolley the mixer is wheeled in the bowl.

...more

Double twist wrapping machine

This machine is used for packaging Ball Lollipops in Double Twist style. The lolipop may be stamped or molded with or without center filling (Pasty or firm center or up to about 15%).The machine uses all commercial packaging materials, outer wrapper such as cellophane and P.V.C, inner wrapper such as waxed paper and paper foil. The machine is fully automatic including No-Paper mechanism.

Capacity : 225 to 250 Wrap/min.

...more

DOUBLE SIDE TWIST CANDY WRAPPING MACHINE

This machine is used for packaging hard candies of round, oval or elongated in double twist wrap technique. The candies may be stamped or molded with or without center filling (pasty or firm center of up to about 15%). The machine uses all commercial packaging materials, outer wrapper such as cellophane and P.V.C, inner wrapper such as waxed paper and paper foil. The sugar boiled sweets are charged into the S.S Hopper from where they are released on to the rotary format by an automatically controlled vibrator. The paper flows from the paper feed station, cut to appropriate length & the sweet is lifted along with folded wrapper in to the twisting turret. The sweets are held in position by the rubber gripper and the twisting operation is performed mechanically by twisting fingers on both sides & then it is further collected from delivery chute.

Capacity : 300-325 Wrap / min

...more

Die

This is a new spring type die, it consists of big and robust punches. The Die is manufactured using best quality material. EXTREME precision is maintained by the use of CNC machine.Thus it produces perfect and uniform shape of candies. Warm candies are cooled in Cooling Conveyor before being fed to the Wrapping Machine. Warm Candies from the Tablet forming Machine are cooled after passing through three belts of galvanized wire mesh. A blower is fitted over these belts which are of 4,8 & 12 inches in width.

...more

cooling drum

A most efficient cooling drum with a stainless steel diameter that is machined for concentricity and polished to a fine finish to assure easy release at the scrape off. Cooling drum is the top-of-the-range stainless steel option for cooling chocolate or compound after the enrobing process. It includes the multi zone cooling evaporators, accurate temperature controls and Stainless steel finish. Directly from cooker, you can pour the mass into the hopper of cooling drum. As the drum rotates, mass guides along and is cooled over its surface. The scraper is provided for passing on the mass to conveyor. A pump is provided for continuous lubrication which prevents the sticking of mass on drum.

...moreBe first to Rate

Rate ThisOpening Hours