Water Cooled Heat Exchangers

Water Cooled Chilling Plants

Vikrant Comp Tech System is reputed for the high quality and cost effective Water Cooled Chilling Plants. We have an expertise in manufacturing customised cooling plants which meet the requirements of the clients to the minutest details. All the major components of the Water Cooled Chilling Plants are procured from reputed & well known OEMs and we can assure you of their authenticity and durability. The high quality of our product has gained a huge number of valuable clients and we always put in dedicated effort to make this relation stronger. Main Features Fully automatic Water / Air CooledOpen / Hermetic Compressor (Optional)Wide range of Capacity from 3 TR to 300 TRCompressor, Motor, Extension Valve, HP / LP switches, Temperature controller, Electrical Control, Dryer, etc. are of best quality possible and very reliable in all conditions. Uses Highly effective in cooling waterHygienic

...more

Vertical Compressor

We are reckoned as one of the major Industrial Air Compressor Manufacturers from India. We offer Air Compressor that is used in various industries. The Different Types of Compressors Manufactured By Us are : Single Stage CompressorTwo Stage CompressorMulti Stage CompressorVertical CompressorSingle & Two Stage Vacuum Pumps Features : These compressors are ideal for a textile, plastic industries, garages, petrol pumps, blowering, pneumatic operations, etc.Bare compressor or complete package comprising of compressor, motor with pulley & belts, after cooler, air receiver & panel, mounted on skid.

...more

U Tube Heat Exchanger

Vikrant Comp Tech System Shell & Tube type Heat Exchangers & Fin Tube Heat Exchangers are built in a wide variety of sizes. Length of the Industrial Heat Exchanger varies from 3 feet to 40 feet over the tube heads. The Heat Exchangers are designed for a pressure of 20 Kg per sq.cm gauge on shell side and tube side. The Steam-Heat Exchanger is fabricated as per TEMA / ASME unfired pressure vessels codes & ASHRAE standards requirements. Heat Exchangers for sea water marine application or with steels shells are also offered & designed as per customer specific requirements. We are counted as one of the reliable Heat Exchanger Manufacturers and Exporters from India. Shell & Tube Heat Exchangers Vikrant Comp Tech System Shell & Tube type Heat Exchanger is built in a wide variety of sizes. The Steam-Heat Exchanger is fabricated as per TEMA / ASME unfired pressure vessels codes . Heat Exchangers for sea water marine application or with steel shells are also offered & designed as per customer specific requirements. We are counted as one of the reliable Heat Exchanger Manufacturers and Exporters from India.Before VCTS's nameplate is placed on any unit, the exchanger has been carefully inspected throughout the production process by our highly trained quailty control department. These heat exchangers adhere to the latest technology, as these are specially designed to withstand high pressure & temperature so that they deliver maximum performance. Finned Tube Heat Exchangers Our range of finned tube heat exchanger is especially made to suit the area where air is used as one medium. In this type of exchanger steam or thermic fluid is used as hot medium. The finned tube heat exchangers are manufactured using flat fins, strip wounded fins and wire wounded fins. The high fin area helps in maximum heat transfer.We offer a range of finned tube air coolers that are manufactured by using high grade raw material. Features : High durabilityLow maintenance costTrouble free operation

...more

Tube Bundles

We have been manufacturing direct replacement and new application tube bundles for Shell & Tube Heat Exchangers. We can duplicate any existing Bundle to include dimensions, materials and performance. We can build "U" tube bundles, straight tube "floating" tubesheet bundles, or we can retube fixed tubesheet heat exchangers when the bundle is not removable. VHEPL is not locked into any one material. Most bundles tend to be built with copper tubes and steel tubesheets. VHEPL can offer a wide variety of materials, including: carbon steel, stainless steel, cupro-nickle, admiralty brass and many others. We also offer our special expedited shipment schedules for emergency replacement.

...more

Stainless Steel Storage Tank

Vikrant Comp Tech System manufactures excellent quality Tanks and Coils to store water that are manufactured using advanced technology. We manufacture the tanks in various specifications & according to customers' requirements. Our team of engineers are expert in the field and make the tanks that meet the standards required by customers. We offer stainless steel (S.S.) Chemical Storage Tanks which can be used for any kind of fluids. Due to high quality of material used in manufacturing the tanks, they are highly durable and also require less maintenance. Features Non-corrosive, light weight, long lasting and leak proof. Wide range of capacity. Uses To store all types of fluids in industries as well as for household purposes.

Country of Origin : India

Type : Stainless Steel Storage Tank

Material : Stainless Steel

Shape : Round

Feature : Anti Corrosive, Durable, Eco-Friendly

Condition : New

...more

surface condensers

VHEPL Steam Surface Condensers range from small packaged units used in the HVAC industry to large cylindrical condensers used for mechanical drive applications in power plants, refineries, or chemical processing plants. Circular shells to approximately 12 feet in diameter can be supplied to suit a variety of requirements. Because of our considerable experience in condenser manufacturing, our ability to work with exotic materials as well as turbines with different exhaust configurations (down, top, axial), We can closely work with customers to evaluate options that best meet the specific requirements of any project. We manufacture wide range of Surface Condensers & Steam Heaters for Power Plants.

...more

Air Conditioning Compressors Parts

Vikrant Comp Tech System is one of the leading Compressors Parts Manufacturer and amidst the foremost Exporters from India. The product range covered by us includes: Spares for Air-Gas-Air Conditioning Compressors Ingersoll Rand Compressors CPT Compressors K.G. Khosla Compressors Kirloskar Compressors Voltas Compressors Elgi Compressors Atlas Copco Compressors Accessories Intercooler - After cooler - Heat Exchangers Air Dryers /Electronic Auto Drain Valves Electro Pneumatic Unloaders for Compressors All kinds of Teflon packings / sheets. We undertake servicing/overhauling/ repairing jobs for all types of air, gas and refrigeration compressors. We are having experienced team of engineers who are able to solve any problem related to Compressed Air Systems. We are specialized in servicing/ overhauling of reciprocating /screw compressors .We undertake AMC/ turnkey jobs/ compressed air audits/ rate contracts. Moreover, Air Compressor Spare Parts can be obtained in different specifications and grades suiting to the needs of customers. Oil less Air Compressor Spare Parts are available at most affordable prices. For More Details Please Click On The Links Given Below :

...more

Shell and Tube Heat Exchangers

We manufacture Shell & Tube type Heat Exchangers in a wide variety of sizes & materials. The Heat Exchangers are fabricated as per TEMA / ASME codes / ASHRAE standards or as per customer requirements. Heat Exchangers are offered & designed as per customer specific requirements. VHEPL Shell & Tube type Heat Exchangers are built in a wide variety of sizes. Heat Exchangers for sea water marine application or with steel shells are also offered & designed as per customer specific requirements. We are counted as one of the reliable Heat Exchanger Manufacturers from India. Before VHEPL's nameplate is placed on any unit, the Heat Exchanger is carefully inspected throughout the production process by our highly trained quailty control department. These heat exchangers adhere to the latest technology, as these are specially designed to withstand high pressure & temperature so that they deliver maximum performance. FEATURES OF VHEPL HEAT EXCHANGERS : High durability Low maintenance cost Trouble free operation

...more

Shell and Tube Heat Exchanger

Shell & Tube Heat Exchangers our Shell & Tube type Heat Exchanger is built in a wide variety of sizes. The Steam-Heat Exchanger is fabricated as per TEMA / ASME unfired pressure vessels codes . Heat Exchangers for sea water marine application or with steel shells are also offered & designed as per customer specific requirements. We are counted as one of the reliable Heat Exchanger Manufacturers and Exporters from India.Before VCTS's nameplate is placed on any unit, the exchanger has been carefully inspected throughout the production process by our highly trained quailty control department. These heat exchangers adhere to the latest technology, as these are specially designed to withstand high pressure & temperature so that they deliver maximum performance.

...more

Pressure Vessels

A Pressure Vessel is a closed container designed to hold gases or liquids at a pressure different from the ambient pressure. Some examples of pressure vessels are; industrial compressed air receivers, domestic hot water storage tanks, diving cylinder, recompression chamber, distillation towers, autoclaves, etc. Many other vessels used in oil refineries and petrochemical plants, and storage vessels for liquefied gases such as ammonia, chlorine, propane, butane and LPG are also categorized as pressure vessels. Industrial Pressure Vessels can theoretically be of any shape, but shapes made of sections of spheres, cylinders and cones are usually employed. Boiler Pressure Vessels are designed to operate safely at a specific pressure and temperature. A vessel that is inadequately designed to handle a high pressure constitutes a very significant safety hazard. Because of that, the design and certification of pressure vessels is governed by design codes such as the ASME Boiler and Pressure Vessel Code.

...more

Pressure Vessel - 02

A Pressure Vessel is a closed container designed to hold gases or liquids at a pressure different from the ambient pressure. Some examples of pressure vessels are; industrial compressed air receivers, domestic hot water storage tanks, diving cylinder, recompression chamber, distillation towers, autoclaves, etc. Many other vessels used in oil refineries and petrochemical plants, and storage vessels for liquefied gases such as ammonia, chlorine, propane, butane and LPG are also categorized as pressure vessels. Industrial Pressure Vessels can theoretically be of any shape, but shapes made of sections of spheres, cylinders and cones are usually employed. Boiler Pressure Vessels are designed to operate safely at a specific pressure and temperature. A vessel that is inadequately designed to handle a high pressure constitutes a very significant safety hazard. Because of that, the design and certification of pressure vessels is governed by design codes such as the ASME Boiler and Pressure Vessel Code.

...more

Pressure Vessel - 01

A Pressure Vessel is a closed container designed to hold gases or liquids at a pressure different from the ambient pressure. Some examples of pressure vessels are; industrial compressed air receivers, domestic hot water storage tanks, diving cylinder, recompression chamber, distillation towers, autoclaves, etc. Many other vessels used in oil refineries and petrochemical plants, and storage vessels for liquefied gases such as ammonia, chlorine, propane, butane and LPG are also categorized as pressure vessels. Industrial Pressure Vessels can theoretically be of any shape, but shapes made of sections of spheres, cylinders and cones are usually employed. Boiler Pressure Vessels are designed to operate safely at a specific pressure and temperature. A vessel that is inadequately designed to handle a high pressure constitutes a very significant safety hazard. Because of that, the design and certification of pressure vessels is governed by design codes such as the ASME Boiler and Pressure Vessel Code.

...more

Plate Heat Exchangers

We have the most extensive plate heat exchanger range. Vikrant Heat Exchangers has got the optimal technical solution for any possible task. Connections from Ø15 to Ø650 mm covering a liquid flow range from 50 l/hour to 2800 m3/hour. The unique inlet designs and plate patterns ensures a high thermal efficiency and heat transmission for any given pressure drop. VHEPL delivers standard, copper brazed, semi-welded and all-welded plate heat exchangers as well as customized heat transfer solutions for any task. PLATE HEAT EXCHANGERS : 1) Standard Plate Heat Exchangers 2) Semi-Welded Plate Heat Exchangers 3) All-Welded Plate Heat Exchangers 4) Sonder Safe Plate Heat Exchangers 5) Free Flow Plate Heat Exchangers 6) Brazed Plate Heat Exchangers 7) Plate & Shell Plate Heat Exchangers 8) Spiral Heat Exchangers 9) Evaporator & Condenser

...more

oxygen compressors

Oil Separators

Your quest for excellent quality Oil Water Separators ends at Vikrant Comp Tech System. We bring forth qualitative range of Oil Water Separators that are designed to meet various industrial applications. Used for the purpose of separating oil from refrigerant gas, Wholesale Oil Separators are highly demanded by our esteemed client�s located al over the globe. Known for their high performance and precision, VCTS Oil Separators can be obtained in unlike specifications. We are tagged as one of the most principal Fuel Oil Separators Suppliers from India.

...more

Oil Coolers

We are proud to introduce ourselves as one of the leading Industrial Oil Cooler Manufacturers from India. Hydraulic Oil Coolers are used in variety of industries for desired applications. From standard to highly specialized, these units come in a full range of sizes and materials. These units are usually specified as floating head (TEMA type "W") with O-Ring and weep hole for early leak detection. The units can be designed to ASME Section VIII, Div 1, API 612, 618,618, & 660, TEMA Class R, C & B as well as customer supplied specifications. Heat Exchanger-Oil Cooler can be obtained at most competitive prices of the industry.

...more

Oil Cooler

We are proud to introduce ourselves as one of the leading Industrial Oil Cooler Manufacturers from India. Hydraulic Oil Coolers are used in variety of industries for desired applications. From standard to highly specialized, these units come in a full range of sizes and materials. These units are usually specified as floating head (TEMA type "W") with O-Ring and weep hole for early leak detection. The units can be designed to ASME Section VIII, Div 1, API 612, 618,618, & 660, TEMA Class R, C & B as well as customer supplied specifications. Heat Exchanger-Oil Cooler can be obtained at most competitive prices of the industry.

...more

Non-Return-Valves-02

We manufacture a comprehensive range of Non Return Valves that are suitable for steam, water, refining, oil, gas and various chemical applications. Non Return Check Valves are available in fabricated, forged and casted body. This valve is globally demanded for its high performance and effectiveness. At VCTS you can avail first-rate non-return valves in different sizes and specifications. We are recognized as one of the most outstanding Forged Steel Non Return Valves Exporters from India.

...more

Non Return Valves-01

We manufacture a comprehensive range of Non Return Valves that are suitable for steam, water, refining, oil, gas and various chemical applications. Non Return Check Valves are available in fabricated, forged and casted body. This valve is globally demanded for its high performance and effectiveness. At VCTS you can avail first-rate non-return valves in different sizes and specifications. We are recognized as one of the most outstanding Forged Steel Non Return Valves Exporters from India.

...more

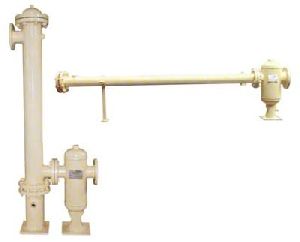

Intercooler

VCTS Intercooler is specialized heat exchangers that are used in multi-stage compressor systems to cool the pressurized air or gas. Water to Intercooler are designed for direct / floor mounting arrangement. These are available in standard horizontal / vertical models, with or without built in Moisture Separators.

...more

Inter Cooler

VHEPL Inter Cooler is specialized heat exchangers that are used in multi-stage compressor systems to cool the pressurized air or gas. Water to Intercooler are designed for direct / floor mounting arrangement. These are available in standard horizontal / vertical models, with or without built in Moisture Separators.

...more

Industrial Heat Exchangers

Industrial Condensers

Vikrant Comp Tech System offers cleanable Shell & Tube Integrally Finned Water Cooled Condensers from 3TR to 200TR capacity. These Industrial Condensers are built in a wide variety of sizes .The Condensers are designed for a pressure of 20 Kg per sq.cm gauge on shell side and 7 Kg per sq.cm gauge on water side. Industrial Steam Condensers are tested up to 28 Kg per sq.cm gauge on the shell side & 10 Kg. per sq.cm gauge on water side.Condensers for sea water marine application or with steel shells are also offered & designed as per customer specific requirements. We are tagged as one of the illustrious Condensers Manufacturers and Exporters from India. VCTS manufactures various types of shell and tube condensers, from standard fixed tube shell type to floating head or "U" tube bundle to suit different process conditions with strict quality assurance and in full compliance with international code and code like ASME sec. VIII and TEMA.

...moreBe first to Rate

Rate ThisOpening Hours