Mortice Chisel Set

We are offering Carpenter tools.

Mortice Chisel

We are offering Carpenter tools.

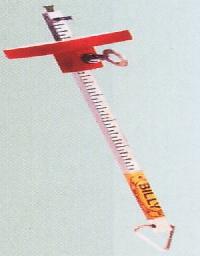

Marking Guage

We are offering Carpenter tools.

Hose Pipe Clamp-03

hose pipe clamp

Carpenter tools

We are offering Carpenter tools.

Briquetting Plant

the project :this project is simply process of converting agro-forestry waste into briquettes/bio-coal. “best from waste”- the biomass briduetting is the best renewable energy project for better ecology and economy. it’s a completely eco-friendly green energy project.energy is the key factor in economic development of every country. as we are well aware about the demand of energy is increasing every day and supply sources are limited. it is globally red alert for fossil fuel like petrol, kerosene, natural gas, lpg, lignite, and other coal. this has made a huge gap between the demand and supply of energy. renewable energy is the only solution which can fill this gap. there is a worldwide acceptance to this project. most of the advance countries had adopted this concept and retaining their natural resources.this renewable energy project is ideal for the agricultural-based countries like india, sri lanka, pakistan and african countries as there are a huge availability of agro-forestry waste.it is the best project to generate revenue from agro-forestry waste, save the global environment and to produce green energy. for example: india produces about 350 million tones of agricultural waste every year and uses only 20 % of the same.this project is essential for converting low density biomass into high density bio-mass fuel that is called briquettes/bio-coal or white-coal. briquettes are made from agricultural or forestry waste, which can effectively, used to replace solid fuels (coal or wood) and can easily use various kinds of thermal applications.our briquetting plant technology doesn’t require any binder/chemical during the process. any type of biomass itself contain lignin in solid form, during briquetting process due to heavy pressure & heat this solid lignin convert into liquid & act as a natural binder so there is no need to add any chemicals or other foreign substance for binding process. therefore, it came to be known as binder less technology.adoption of briquetting technology will not only create safe and hygienic way of disposing the waste but also the new business concept by converting waste to green energy and contributing towards a better ecology and economy of country.incentives declared : not requirement of noc from pollution control board.priority for finance for nationalized bank or ngo.salient features of the project :increasing the demand of finished product (briquettes) day by day.easily availability of various type of raw materials.promoting these industries as a prime renewable energy project throughout the world.excellent project viability.payback period within 2 years.pollution free and no hazard in the project.eco-friendly renewable green energy project.product :the raw material, finished product and usagesthe raw material- the bio-mass /agro-forestry wastewe know that agricultural waste is generated million of tons every year. these are either non used or burnt inefficiently in their loose form causing air pollution. handling and transportation of these materials is also very difficult due to their low density.vinayak exports provides the solution to use this wastage into best form. these wastage can easily convert into high-density fuel (briquettes) with the help of biomass briquetting plant. in india & other agro base countries have lot of scope for this project due to huge availability of biomass.specification of raw material :size : max. 20 mm.moisture : below 10%.major agro-wastes available : [calorific value cal/kg given with ] groundnut shell : 4000 k sunflower stalk : 4000 k sugarcane baggasse : 4300 k jute waste : 4000 k caster seed shells/stalk : 4000 k palm husk : 3900 k saw dust & wood chips : 3900 k soybeans husk : 3800 k cotton stalks / chips : 3700 k veneer resides : 3300 k bamboo dust : 3800 k barks & straws : 3500 kcoffee husk : 3800 k forestry waste : 3000 k tobacco waste : 3500 k coir pitch : 3000 k tea waste : 3700 k rice husks : 3500 kpaddy straw : 3600 k seeds cases : 3800 kmustard stalk / shell : 4500 k others so many : 3000 k apx. wheat straw : 2200 k rate of raw material (approx):the rate of raw material (bio-mass) may be free of cost to rs. 1000/mt in india.(the rate of raw material may be varied as the availability and location.)process of raw material (if required) :most of biomasses can be used directly as per specification.raw material has more then 10% of moisture contains, it’s required drying process.if the raw material is longer then 20mm, it’s required to cutting process.finished product– briquettesbriquettes are ready substitute of lignite/coal/wood in industrial boiler and brick kiln for thermal application. biomass briquettes are non-conventional source of energy, eco-friendly, renewable in nature, non polluting and economical. it’s made through binder less technique without use of any type of chemical so it is 100 % natural. briquettes have high specific density (1200 kg/m3) and bulk density (800 kg/m3) compared to 60 to 180 kg/m3 of loose biomass. these can withstand the stocks of long distance transport, loading/unloading and transportation costs are much less and storage requirement is drastically reduced. compared to fire wood or loose biomass, briquettes give much higher boiler efficiency because of low moisture and higher density.use of bio coal is increasing day by day and has very demandable market due to its fuel cost saving and pollution free characteristic.briquettes is an ideal fuel due to eco friendly & renewable energy fueleconomical and cheaper than other solid fuels i.e. coal & wood.higher thermal calorific value around 4000 kcal/kg. pollution free because there is no sulfur or any hazardous material.lower ash content 2-5%. there is no fly ash when burn.consistent high burning efficiency due to the low moisture.contain high density & higher fix carbon value.easy for transportation, feeding & combustion due to unique shape.combustion is more uniform compared to other coal.demandable market due to high rise in fossil fuels price.applications of briquettes / bio-coal :briquettes are widely used for any type of thermal application like steam generation in boilers, heating purpose, drying process & gasification plant to replace existing conventional fuel like coal, wood & costly liquid fuel like fo, diesel, ldo, kerosene etc. use of briquettes as a fuel for green energy has shown very promising results.use of finished briquettes in various industries ( thermal applications ) : gasifier system applicationsvegetable plantsceramic industriestextile unitrefractory industriesspinning millsolvent extraction plantlamination industrieschemical industriesleather industriesdyeing unitsbrick making unitsmilk plantrubber industriesfood processing industriesany industrial thermal applicationbio coal is a forth coming fuel of the world. it’s a high quality asset towards economical, ecological & advanced environmental company policy.briquetting plant-model :according to production capacity, size of raw material and finished product, vinayak exports has developed three models of briquetting plant :super-60 modelsupreme-70 model jumbo-90 modelsuper-60 modelsuper-60 is first model developed by vinayak exports. although only drawback of this model is that it requires hammer mill for powder form of material yet till now it is best model that require medium production capacity with minimum capital invest.production capacity : 600-750 kg/hrfinished product size : 60 mm diameterfinished product shape : cylindricalraw material form : powderyprocess cost/mt (approx.) : irs.450/-supreme-70 model :this is latest version of super-60 model. this model is best for those that want more production than super-60 (750 to 1000 kg/hr) but want less capital investment than jumbo-90 model. it is also required hammer mill for converting powdery form of the raw material. production capacity : 750-1000 kg/hrfinished product size : 70 mm diameterfinished product shape : cylindricalraw material form : powderyprocess cost/mt (approx.) : irs.400/-powder making unit :as above mentioned that both models will accept only powdery form of raw material so it must required powder making unit. powder making unit consist parts of : screw conveyor : regular feeding of raw material up to hammer mill hammer mill : reducing size of raw material up to powdery formblower, pipe, cyclone & air lock : transporting the processed raw materialholding bin : storage of powdery raw materialscrew conveyor : convey the material up to briquetting presslayout of super-60 & super-70 :briquetting press hammer millscrew conveyorscrew conveyor for r.m. feedingholding biospace for raw materialcycloneground flooring rotary air lockdie holder (output of briquettes)connecting pipe main electric motor blower briquetting plant jumbo-90 :the flagship product of vinayak exports is jumbo-90 model. it has jumbo production capacity with minimum operating cost compare than other models. some latest modifications make it more economical and most effective model.our latest briquetting plant jumbo -90 :production capacity : 1200-1500 kg/hr.finished product size : 90 mm diameterfinished product shape : cylindricalraw material form : up to 20 mm sizeprocess cost/mt (approx) : irs. 350/-the features of jumbo-90 :maximum production capacity.heavy structure with standard design.acceptability up to 20 mm size of raw material (no need of powder form).easy operating system.high-density of finished product with 90 mm diameter.lowest production cost per mt due to state of art technologylow electric consumption due to direct feeding without hammer milllow maintenance cost.low management cost due to high production capacity.no loss of production & air pollution due to direct feeding systemjumbo – 90 :front elevation with side conveyorbriquetting pressload wheelkupyreduction gearscrew conveyorelectric motorbricks wall of shadeground flooringspace for raw materialopen terracewater tankjumbo – 90 :side elevation with backside conveyorbriquetting pressload wheelkupyreduction gearscrew conveyorelectric motorbricks wall of shadeground flooringspace for raw materialopen terracewater tankmain electric motorflat beltdie holdertechnologyat present in india binderless technology is most popular & successful. this technology has been adopted to suit indian condition according to the characteristics of raw material available from various in different seasons. this binder less briquetting technology is based on very high compact characteristics of combustibles cellulose agro waste such as bagass & saw dust, groundnut shells, rice husk, cotton stalk, custard shell etc. into cylindrical briquettes through high process heat. briquetting technology is well developed in advance countries like switzerland , u.s.a., denmark, canada, brazil, u.k. etc.briquetting plant consists of two major units.sizing up unit ( powder making units briquetting unit )briquetting unitsizing up unit :the various raw materials available from regions converted into powder from & homogeneous mixing of different available raw materials are made & then the said powder form becomes input for briquetting press (unit). this sizing up unit requires only in super-60 (60.mm die briquettes) and have required by the material handing equipment like conveyor, blower, cyclone etc.briquetting press : prepared homogeneous raw material feed to briquetting press by screw conveyor for regular feeding. in briquetting press it passes through taper die and punch & due to high pressure & heat powder from conveyor into solid cylindrical briquettes due to pressure & heat, lignite content of all raw material it transfers in liquid form & act as a binder so in this technology there is no need to add any binder to form briquettes.there are two main models of briquetting press…….super – 60 : briquettes produces from this press is 60mm dia. and on production basis it is two type, one gives 550 kg./hrs. and second gives 750 kg./hrs.production. production capacity : 750 kg./hrs. cam shaft type size : 70mm diametershape : cylindricalraw material form : powderyproduction cost : rs. 400/- irs.throw 90mm total stroke length 180mm jumbo – 90 : briquettes produces from this press is 90mm dia. this press does not require powder making units and it gives 1500 kg./hrs production.jumbo-90 : 1500 kg./hrs. cam shaft type size : 90mm diametershape : cylindricalraw material form: up to 25mm max.production cost : rs. 350/- irs.throw 100mm total stroke length 200mm. super - 60front elevationbriquetting pressload wheelscrew conveyorholding bincycloncyclon standcovered space for storage of powder form raw materialopen terracewater tankrcc bunground flooringsuper - 60side elevationbriquetting pressload wheelscrew conveyorholding bincycloncyclon standcovered space for storage of powder form raw materialconveying pipeblowerhammer millscrew conveyor for raw material feedingspace for raw materialground flooringdie holdermain electric motorflat beltland layoutbriquetting press [ foundation 16’ x 5’ ]shed for briquetting plant 25’ x 30’ height – 15’reserved space for second briquetting press.cooling line for briquettes.shed for briquettes. [ galvanized roof 40’ x 40’ height – 20’ ].entry gate. [ 15’ long ]office building : two smaller room 10’ x 10’compound wall.proposed labour quarter [ 3 to 4 smaller rooms ]shed for raw material storage [ galvanized roof 60’ x 40’ height – 20’ ]conveyor for raw material feeding.open space for raw material storage.

...more

Axle Shafts

cast iron castings

hand tools

Hose Pipe Clamps

Sheet Metal Parts

Be first to Rate

Rate ThisOpening Hours