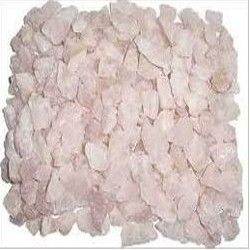

Acidic Ramming Mass

Get Price Quote

M/S. Adinath Grinding Mills is glad to introduce its high quality product Acidic Ramming Mass. This range of Acidic Ramming Mass is successfully being used in Mains, Medium, and High Frequency Induction furnaces of a variety of makes, viz. G.E.C., H.B.B., Pioneer Inductrotherm, Electrotherm etc. As, the name suggests this product is acidic in nature and has a melting point of 3274°F (1700°C).Our Acidic Ramming Mass gives wholly satisfactory results for super heating of metals up to 1700 Degree Centigrade. This range of minerals is offered to the clientele at competitive market prices. The basic use of Acidic Ramming Mass is in the lining of induction furnaces. It provides a smooth working of furnaces, an optimum output, and a better metallurgical control due to its better quality. Our qualified and experienced professionals strictly observe the manufacturing of Acidic Ramming Mass. Our magnetic process plays a significant role, so that the manufacturing is iron-free and the granules have a proper composition according to the furnace-capacity. Granulometric composition of commercial silica ramming mass size percentage 4 mm to 1 mm 33 % 1 mm to 0.20 mm 30 % 0.20 mm to 0.06 mm 17 % 0.06mm & Below 20 % Specified Benefits of the furnace The optimization of our granulation mixture is at par, with the capacity of the furnace which in turn provides us the maximization of results. Due to a low count of binders, fire clay and moisture, ramming mix is characterized by thermal stability, corrosion resistance and wears resistance in competence with plastic refractory. This product is basically suitable, for lining the iron melting coreless induction furnace. Binder is premixed according to the specifications of our clients. 3274°F (1700°C) is the maximum limitation which one could reach. Through a rigorous process of optimizing the mixture of granulations, we achieve major results. We are a famous manufacturer, providing the material according to the need of our clients. This company provides specific material, for a variety of scraps, end products and related to numerous factors. Our Acidic Ramming Mass is available in a dual variety Normal Grade This grade has a range of 98.50 % to 99 % Silica amount, due to which it has a vast usage as Silica Ramming Mix. It easily fits into the common economic statement i.e. the best goods at the cheapest rate. Normal Premix Grade Keeping in view, of our client`s need we provide this pre mixed version of Boric acid. The most commonly used mixture of Normal Premix, has a percentage of 1.1 in our Indian markets. Features High on purity Resistant to abrasion Durable High Refractoriness High Spalling Resistance High Resistance to Cracking Low Sintering time High corrosion resistance towards liquid metal & Slag Minimum expansion & contraction at high temp High electrical resistively to prevent short circuiting Free From Iron oxide Grain Size mixed according to the capacity of furnace Uses Lining the iron melting coreless induction furnace Better metallurgical control Cement industry Glass and glass-making products Ceramic & Chemical industries like sanitary ware, Tiles & Lime industries Iron & Steel industries including Melting, Rolling, Forging & Heat Treatment industries Ferrous & Non-Ferrous metal industries Fertilizer & petrochemical industries Furnace Manufacturers & Consultants We manufacture Ramming Mass for all sizes of Induction Furnaces i.e. 1000kg (1 Ton) to 300000kg (30 Tons) Furnace There are various grades of Ramming Mass : Quartz Based Silica Ramming Mass (ASS108) Super Semi Grade Quartz Based Silica Ramming Mass (ASSS108) Snow-White Grade Quartz Based Acidic Ramming Mass (ASS1008) Super Semi Grade Quartz Based Acidic Ramming Mass (ASSS1008) Snow-White Grade Quartzite Based Silica Ramming Mass ((ASB108) Quartzite Grade Quartzite Based Acidic Ramming Mass (ASSB1008) Quartzite Based

Acidic Ramming Mass

Get Price Quote

5 Ton (MOQ)

Best Deals from Acidic Ramming Mass

Acidic Ramming Mass

Get Price Quote

20 Ton (MOQ)

We bring forth quality Acidic Ramming Mass, which is manufactured from a qualitative range of base materials. Acidic Ramming Mass offered by us, is stringently checked for zero moisture content by our quality experts. In order to protect Acidic Ramming Mass against any kind of adulteration, we pack it in moisture proof bags and ensure that our range is preheated and mixed with binder-boric acid. Known For : Corrosion resistant Thermal stability High quality Widely Used For The Following : SS Steel Plain carbon steels (M.S.) Alloy Steels Low manganese and low chromium steels All graded cast iron S.G. iron and malleable iron

Acidic Ramming Mass

6 Per

100 Kilogram (MOQ)

Pure Acidic Ramming Mass

Get Price Quote

Owing to our unmatched and efficient way of working, we have risen as promising suppliers in the markets of Kolhapur(India) Irrespective of it being a wholesale or retail order, we can deliver it timely. We have shipping resources on reserve all year round to make sure delivery of our items is bother free. Product Description : With immense market knowledge, we have been able to provide optimum quality Acidic Ramming Mass Premix Boric Acid Grade. Approx Price - Rs 12,000 / Metric Ton Price Range - 12000 - 14000 / Metric Ton Other Details : We supply premix grades of Acidic Ramming Mass We supply premix with boric acid 1% for Steel, 1.2% for SG Iron and 1.4% for Cast Iron

Premix Acidic Ramming Mass

Get Price Quote

If you are looking for a Silica Ramming mass for Ladle Lining, you are in the right place. Our company Kirti Mineral Works is a reliable and trusted manufacturer and supplier in the country today. We have a Silica ramming mass that is made with good quality materials. Advantages of Silica Ramming Mass • When using ramming mix in induction furnace, the neutral ramming mass performs much longer service life compared with silica ramming mass, which can save much labour time and furnace baking time, thus can save much money for steel plants. • Additives a, long and stable service life to get high efficiency • Easy to be installed and maintenance, saving time and labour cost Why Choose Products From Us? Customers choose us and get our products for many reasons. Some of the reasons why we have gained popularity and customers are rising day by day are as follows. Good Quality Products The products of our company are made with good quality raw materials. The raw materials that we use are quality assured by our experts and professionals and then used in the production process. Better Customer Service We believe in customer satisfaction. This is why we leave no stones unturned to provide our customers with the best services and products of their choice. Choose us and order our products today. Call us and speak to our executives if you have any questions or queries.

Acidic Ramming Mass

2,800 - 3,500 Per Metric Ton

20 Metric Ton (MOQ)

Acidic Ramming Mass

Get Price Quote

It is quartz based ramming mix widely used in low cost melting of Mild steel, Alloy steels, Ni-hard, Ni-Resistant Chrome Irons, Ductile and Malleable Irons.The same is available in PREMIX variant where homogeneous mixing of boric acid as a binder is done.

Acidic Ramming Mass

Get Price Quote

The company has emerged as a highly acclaimed Manufacturer, Exporter and Supplier of Acidic Ramming Mass in Salem. The company offers a premium quality range of the Acidic Ramming Mass to the clients all across the globe. The company ensures the timely delivery of the Acidic Ramming Mass at the best market rates. Minimum Order Quantity : 1 FCL

Acidic Ramming Mass

Get Price Quote

Acidic Ramming Mass that we provide is used in the lining of induction furnaces. Quality of Acidic Ramming mass is directly related to the heating performance of the furnaces. Better quality of lining results in the smooth working of furnaces, optimum output and better metallurgical control. Our Acidic Ramming Mass is manufactured under strict supervision of qualified & experienced work force, keeping all these aspects in mind. Proper check is exercised on magnetic process to assure iron free material and to assure proper composition of granules according to furnace capacity. The granulation of the mix is optimized, keeping in view, the furnace make and capacity for best results. Acidic Ramming Mass, provided by us, is characterized by thermal stability, corrosion resistance and wear & tear resistance because it contains less binders, fire clay and moisture compared to plastic refractories. Our superior quality Acidic Ramming Mass is stringently manufactured under strict supervision of qualified and experienced work force. Proper check is exercised on magnetic process to process iron free Acidic ramming mass and to assure proper composition of granules according to furnace capacity. Granulometric Composition Of Commercial Acidic Ramming Mass : Size Percentage : 4 mm to 1 mm 33 % 1 mm to 0.20 mm 30 % 0.20 mm to 0.06 mm 17 % 0.06mm & Below 20 % Basic Ramming Mass : Basic Ramming Mass is suitable for induction Furnaces for production of high quality alloy steel, mild and low allow steel. Furnace Specific Benefits : We are the only manufacturer to give material as per the furnace capacity and make of the user. The granulations of the mix are optimized keeping in view the furnace make and capacity, thus giving maximum and best results. Our Acidic Ramming Mass : Recommended For Lining the iron melting coreless induction furnace Premixed with binder to customer's specifications Maximum recommended use limit - 3092oF (1700oC) We manufacture Ramming mass under completely controlled conditions and the formulation is prepared with consultations of major furnace manufacturers. It is best suited to control : Reactivity of the refractory Temperature in which reactivity takes place Sintering characteristics of the lining Density and strength of the lining

Acidic Ramming Mass

Get Price Quote

We “Shree Ratan Minerals” are proud to introduce ourselves as one of the leading suppliers/manufacturers of industrial products such as: Acidic Silica Ramming Mass (pre-mix or post-mix), Quartz Grains & Powder, Mica, Feldspar and other related minerals. Made from premium quality material each of our delivered products has defect-free finish and widely used in various industries.

acidic ramming

Get Price Quote

Suitable for ramming of 10,15.20 and 25mt furnace/foundry. with silica (sio2) rn98 to 99%.

Brown Acidic Ramming Mass

2,000 Per Ton

27 Ton Ton (MOQ)

Salient features of our Ramming Mass: Free of iron oxide (FeO) High corrosion resistance towards steel & slag Suitable upto 1730ºC High refractoriness to with hold operating temperature Grain-sizes mixed according to capacity of the furnace Low down time for furnace lining Consistent quality (purity 98.65%) High electrical resistivity to prevent short circuiting Minimum expansion & contraction at high temperature (treated) Moisture free and sea worthily packing Our silica ramming mass are widely used for the following: SS Steel Plain carbon steels (M.S.) Alloy Steels Low manganese and low chromium steels All graded cast iron S.G. iron and malleable iron Alloy cast iron Our non-ferrous alloys are used for preparing the mentioned below products: Copper and its alloys Copper-Nickel up to 15% Ni

Acidic Ramming Mass

Get Price Quote

Our Acidic Ramming Mass is extensively used in the lining of induction furnaces. Our company is an eminent Manufacturer, Supplier and Exporter of Acidic Ramming Mass from Jaipur, India. The Acidic Ramming Mass is characterized by thermal stability and corrosion resistance because it contains less binders, fire clay and moisture compared to plastic refractory. In addition to this, proper check is exercised on magnetic process to ensure iron free material and to assure proper composition of granules according to furnace capacity. Chemical Composition : Silica (Sio2) : 99% Alumina (Al203) : 0.04% Ferric oxide (Fe203) : 0.04% Potassium oxide (K20) : nill

High Acidic Silica Ramming Mass

Get Price Quote

5 Ton (MOQ)

We are offering High Acidic Silica Ramming Mass. silica based refractory designed for lining coreless induction furnaces.widely used for melting of gray, ductile & iron foundry.

Tata Acidic Ramming Mass

Get Price Quote

Acidic Ramming Mass

1,750 Per Metric Ton

Acidic Ramming Mass

Get Price Quote

The Acidic Ramming Mass, provided by us, is acclaimed for its quality. We have cemented our presence in the market by offering high quality lot that is prepared using the best grade material and modern work methodologies. Also, the material is sourced from the genuine vendors only. As a respected name in the industry, we make use of only high-grade packaging material for the safe packing of the products. Thus, we ensure zero damage at buyer's end.

Acidic Ramming Mass

Get Price Quote

We offer clients with Acidic Ramming Mass which is useful for various applications. Our range of Acidic Ramming Mass is manufactured under a rigorous production process. The Acidic Ramming Mass available with us is highly demanded in the national and international market. Moreover, we provide customized solution to the clients as per their requirement. Characteristics : Corrosion resistantCan withstand high temperatureAccurate chemical compositionGood thermal strengthResistant against electricityFree from iron oxideHigh refractorinessAvailable in purest form Can be used for metals like : Alloy SteelsAlloy cast ironPlain carbon steels (M.S.)S.G. iron and malleable ironAll graded cast ironSS Steel

Acidic Ramming Mass

Get Price Quote

We are a leading manufacturer and exporter of Acidic Ramming Mass, based in New Delhi. This mass is used for lining induction furnaces. The heating performance of the furnaces is dependent on the quality of mass. The granulation of the mass is enhanced, keeping in mind the make and capacity of the furnace that it is being used to line. The mass has good thermal stability, is resistant to corrosion, and is durable. Chemical Composition : Silica (Sio2) - 99.5% Alumina (Al203) - 0.04% Ferric oxide (Fe203) - 0.04% Potassium oxide (K20) - nill Details : The Typical Granulometric Composition of commercial silica ramming mass is given below for 2.5 to 25 Ton furnace in Acidic & Premix form 0.06 mm - 6 mm.