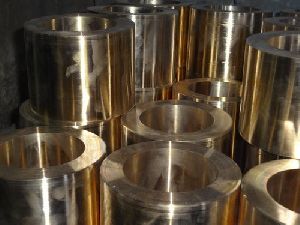

Bronze Centrifugal Castings

900 Per Kilogram

500 Kilogram (MOQ)

Aluminum Centrifugal Pump Castings

900 Per Piece

1000 Piece (MOQ)

Best Deals from Centrifugal Casting

BRONZE CENTRIFUGAL CASTING

700 Per Piece

We are the leading manufacturers, exporters and supplier of this products.

Centrifugal Casting

Get Price Quote

When it comes to centrifugal casting from Jagadhri (Haryana), then the name of Naushahri Lal & Sons is quite preferred by the clients. In the process of sand casting, molten metal is suddenly cooled down using centrifugal force. This makes directional solidification, which is further achieved by heat extractions by metallic mold and high compressive pressure exerted by the centrifugal force. In our factory, centrifugal casting is produced by pouring molten metal into a mold that is being rotated or revolved at a constant speed.Molten Metal is suddenly cooled down by using centrifugal process. This makes directional solidification fronts which is achieved by heat extractions by metallic mould and high compressive pressure exerted by the centrifugal force. In our factory centrifugal casting is produced by pouring molten metal into a mould that is being rotated or revolved at constant speed.

Centrifugal Castings

Get Price Quote

Centrifugal Casting

Get Price Quote

We make available Centrifugal Casting in assorted designs. We do not have to worry about stock-out situations or meeting bulk requirements, as we have an equipped warehouse facility. It has the latest inventory control and management software and helps us maintain continuous product availability. Get in touch with us for obtaining high quality Gunmetal Bushes as we are a dependable supplier in the town.

Synthetic Gypsum Centrifugal Fan Casting

Get Price Quote

Centrifugal Casting

Get Price Quote

This process can be Sand Mouldegorized as similar to that of permanent mold method, Here as the molten metal is being poured, a permanent metal mold revolved about its axis at high speeds ranging from 300 to 3000 rpm. This can be in horizontal, vertical or inclined positions. As a result, the molten metal is centrifugally thrown towards the inside mold wall. There is solidifies after cooling. It’s usually a fine grain casting with a very fine-grained pouter diameter. Molds for Centrifugal castings can be divided into three types : The Permanent Mold: Made of steel, iron or graphite. Inside surface is coated with a thin refractory wash to increase mold life. The mold is preheated before coating, so as to dry the coating and improve the adherence to the mold surface. Rammed Mold: It consists of a steel metal flask, lined with a layer of refractory molding mix. The inside lining is coated with a refractory wash which is baked until dry and hard. Spun or Centrifugally Cast Mold: In the metal flask a predetermined mass of refractory materials in slurry form is poured.The flask on rotation makes the refractory materials centrifuged onto the wall of the flask. The rotation is stopped and the liquid portion of the slurry drained off. It leaves the mold with a refractory coating, to be baked until dry before use. Features of Centrifugal Casting : Castings can be made is almost any length, thickness and diameter. Different wall thicknesses can be produced from the same size mold Eliminated the need for cores. Resistant to atmospheric corrosion, a typical situation with pipes. Mechanical properties of centrifugal castings are excellent Only cylindrical shapes can be produced with this process. Size limited are up to 3m (10 feet) diameter and 15m(50 feet) length Wall thickness range from 2.5mm to 125 mm (0.1-5.0in) Tolerance Limit : On the OD can be 2.5 mm (0.1 in ) on the IS can be 3.8mm(0.15in) Surface finish ranges from 2.5 mm to 12.5 mm(0.1 -0.5in)rms AppliSand Mouldion :Typical materials that can be cast with this process are iron, steel, stainless steels and alloys of aluminium, copper and nickel. Two materials can be cast by introducing a second material during the process. Typical parts made by this process are pipes, boilers, pressure vessels, fly wheels, cylinder liners and other parts that are ax-symmetric. Type of Centrifugal Casting: Semi-Centrifugal Casting Centrifugin

Stainless Steel Centrifugal Casting

Get Price Quote

1 Ton (MOQ)

Centrifugal casting is a process that delivers components of high material soundness. As a result, it is the technology of choice for applications like jet engine compressor cases, hydro wear rings, many military products, and other high-reliability applications. It has also proven to be a cost-effective means of providing complex shapes with reduced machining requirements and lower manufacturing costs as compared to forgings and fabrications.

Centrifugal Castings

Get Price Quote

We are a major Manufacturer, Supplier and Exporter of the finest Centrifugal Castings that are made using excellent quality metals and alloys. The high-performance Centrifugal Castings serve diverse industries like Breweries, Sugar machinery industry, Chemical valve industry etc. The Centrifugal Castings offered by us are known for their sturdiness, chemical resistance and long service life. Available at nominal prices, customers can choose standard sizes or customize as per their needs. Minimum shipping quantity is 500kg.

centrifugal pump casting

Get Price Quote

We are offering Cast-Iron Centrifugal Pumps. These are horizontal pumps: end suction, horizontal, centrifugal coupled pumps with semi open impeller. Our series JCP pumps are centrifugal semi open impeller type pumps smaller volume using less floor space

Centrifugal Casting

1,200 - 1,800 Per Kilogram

500 Kilogram (MOQ)

centrifugal pump casing

Get Price Quote

Centrifugal Pump Housing casting

400 Per Kilogram

We produce the entire range of products by making use of quality-approved raw materials sourced from the trusted vendors present in the market. Also, the inputs are cross checked by our quality experts. Our complete range of product is wrapped in strong, nontoxic, and superior-grade packs that protect the contents inside from damage, moisture, logistic movement, etc. Furthermore, the packaging has product details printed on it. Features : Sturdiness Durable Resistant to corrosion

centrifugal pump casting

Get Price Quote

Back pull out design offers maintenance friendly. Long service life, low operating cost, minimum downtime.Good quality casting with consistent surface finish hence it gives better efficiency. Versatile shaft sealing and gland packing arrangement.Proper Cooling arrangement for mechanical seal reduces chances of seal failure.

Centrifugal Casting

Get Price Quote

OD : 100 mm – 350 mm Wall Thickness: 8 mm and above Height : 350 mm (Maximum)

Centrifugal Casting

1,100 - 1,200 Per Kilogram

10 piece (MOQ)

Available in all copper based alloys

Centrifugal Castings

Get Price Quote

We make sure that there will be no damage to the products that we deliver to the customers. For this, we use high-quality packaging material and hi-tech machines ensuring the same. We give our patrons the choice to make payments online or offline. Our company understands the concerns of its customers. Therefore, we make sure our payment options are safe. These Centrifugal Castings have a high-strength body with a sleek design and are available in different sizes.

Centrifugal Castings

Get Price Quote

As a trustworthy organization, we store the entire lot in a secured manner in our automated and capacious warehouse. The unit is supervised by our team of experts ensuring complete security. Sourced from trustworthy vendors, our entire lot of raw materials has been cross checked against varied quality parameters before using them in the production process. Centrifugal Castings Details : Centrifugal Castings are produced by the vertical centri-casting process. Vertical OD 70 mm to 170 mm Height 150 mm to 310 mm Weight Range 7 kgs to 40 kgs per piece The Centrifugal castings are machined and fabricated to produce finished components as per customers' requirements. Typical Products and Applications Decanter Manufacturers Bowl Cylinders Bowl Cones Conveyor Parts

centrifugal bronze casting

950 Per Kilogram

Centrifugal Casting

750 - 2,000 Per Kilogram

10 Piece(s) (MOQ)

We are offering Centrifugal Casting which are extensively used in different segment such as automobile, railway, Hydro Power Plants and General engineering Industries. We are supplying Aluminium Bronze, brass alloy. phosphorous bronze centrifugal casting,We are using supreme grade raw material with advance technology. We are offering different material grade with centrifugal casting.

Centrifugal Castings

700 Per

centrifugal pump casting

570 Per Kilogram

50 Kilogram (MOQ)

Centrifugal Castings

825 Per Kilogram

Centrifugal casting process is employed to create thin walled cylinders which are noted for its quality especially for the accurate control of the structure. This casting is mainly used for the production of semi finished products that can be further machined to attain good results. A fixed mold rotates continuously in the centrifugal casting. The rotating mold spreads the molten metal centrifugally where it get the structure after cooling. We are one among the very few quality professionals who have mastered this process in the foundry industry within India. Our products casted using the centrifugal casting process are known for their precision, toughness and long lasting life when they are assembled into finished machineries from a variety of industries.

centrifugal pump casing

Get Price Quote

We are offering centrifugal pump casing.

Centrifugal Castings (01)

Get Price Quote

We are Reckoned as the Prime Manufacturers, Suppliers, Exporters, and Importers of Superior Quality Centrifugal Castings. Our Range of Centrifugal Castings is Produced Using High Quality Carbon Steel, Low Alloy Steel, Stainless Steel, and Cobalt Base Alloys. Assured of High Tensile Strength and Corrosion Resistance, Our Centrifugal Castings are Widely Applicable for Use in Liners for Governing Valves in Power Turbines, Parts of Centrifuge for Separation and Filtration of Fluids Solids, Seat Insert for Process Valves.

Copper Centrifugal Casting

850 Per Kilogram

Centrifugal Gear Casting

1,000 Per Kilogram

100 Kilogram (MOQ)

Vertical Centrifugal Castings

Get Price Quote

Backed by rich industry experience, we are offering a high quality range Centrifugal casting vertical. The offered casting vertical is fabricated by our professionals in compliance with the set industry norms using superior grade raw materials procured from reliable sources of the industry. Appreciated for rigid construction, perfect finish, high strength, corrosive resistant nature and durability, this is highly demanded in the market. The offered Centrifugal casting vertical is available in a variety of specifications and can be custom designed as per the clients needs within the stipulated time frame.

Centrifugal Castings

7,000 Per Piece