Ultra Heat Resistant Conveyor Belt

Ultra Heat Resistant Belts are developed & designed to carry material under extreme high temperature ranging from 180 degrees to 250 degrees. Before, taking a belt it is requested to discuss the temperature & material with us to enable us to recommend you the as appropriate belt.

...more

Steel Cord Conveyor Belt

Widely used for applications which involve high belt breaking strength, heavy load transportation at high speeds, with long centre distances or steep gradients; offering low elongation properties and long service life. Belt and cord construction varies depending on the nature of the application. Transverse reinforcements can be included in the belt construction to endure the most extreme conditions.

...more

Side Wall Conveyor Belt

Offering textile or steel cord construction base belts that are cross stabilized using either polyester mono filaments or steel rods, varying in construction depending on application requirements. ideal for vertical incline conveying, the fabric reinforced flexible sidewalls and cross cleats are hot vulcanized onto a cross stabilized base belt, providing pocket protection for the product being conveyed.

...more

Rubber Sheet

Rubber pulley lagging can reduce slippage and extend service life of conveyor belt & pulley as well as increase friction coefficient. It is available in diamond design.

...more

Rough Top Conveyor Belt

The rough top profile is ideal for fragile material and lightweight packed goods. It is also used in inclined surfaces. The special surface absorbs vibrations and impacts and also prevents material from slipping back. Special features are as under: 1) provides excellent grip between belt top and packages, such as cartons, jute packages. 2) black cover for utility applications. 3) tan cover for non marking applications such as packaged food. 4) available with bare back - bottom cover, to give excellent grip to the conveyor belt.

...more

Pulley Lagging Rubber Sheets

Rubber pulley lagging can reduce slippage and extend service life of conveyor belt & pulley as well as increase friction coefficient. It is available in diamond design.

...more

Plain Conveyor Belt

Textile belt made using NN / EP synthetic woven fabric, skim inter plies and rubber interfaces; the thickness of which varies according to the type of application. Low elongation polyester warp fiber holds the belt tension, with more elastic polyamide weft fiber giving good trough-ability. Used for conveying all types of materials under average to severe conditions.

...more

Pipe Conveyor

The pipe conveyor is an enclosed curve going transportation system for all kinds of bulk materials. At the loading and discharging points, the conveyor system is identical with open troughed conveyors. The difference starts after the loading point, where the belt is formed into its typical tubular shape by special idler arrangements over a certain distance and finally is led through idler panels with hexagonal cut outs and offset idler arrangement. At the discharging point, the belt opens automatically after the final idler panel and transfers the material to its next destination. Due to its tubular shape, the conveyor is able to manage horizontal and vertical curves as well as high inclinations. The enclosed transportation system not only protects the conveyed material against external influences such as climatic conditions, it also avoids material loss and spillage and thus, protects the environment.

...more

Heat Resistant Conveyor Belt

Heat resistant belts have found wide acceptance in various industries , heat resistant belts are required for transporting materials above temperature of 60â°c. It is used for handling material like sinter ,coke, phosphate and clinker etc). As per indian standard, we have heat resistant belts in four different types which has been categorized as below. Hr â�� t1 (suited upto 120 deg c) - - our range of hr (t1) conveyor belts are suitable to convey material in continuous temperature of 125 degree centigrade for coarse materials and 100 degree centigrade for fines. Maximum intermittent temperature upto 125 mainly used in paper, foundries, chemical & fertilizer plants etc. hr â�� t2 shr (suited upto 150 deg c) - our range of shr (t2) conveyor belts are suitable to convey material up to 125 degree centigrade for fines and 150 degree centigrade for coarse material. Maximum intermittent temperature upto 150 ,these conveyor belts are mainly used for conveying sintered ore, pellet, coke, and clinker etc. Hr â�� t3 uhr (suited uptp 200 deg c) - our range of shr(t3) grade conveyor belts are used for high temperature applications, it is suitable to convey material in continuous temperature of 150 degree centigrade and a peak temperature of 180 degree centigrade. Maximum intermittent temperature upto 180 these conveyor belts are mainly used to handle red hot materials such as cement, clinker, sintered ore and phosphate.

...more

general purpose conveyor belt

We offer wide range of grade m-24 conveyor belts suitable for conveying normal temperature material maximum up to 60 degree, it is constructed with fabric (carcass) and rubber compound, rubber cover is compounded from the best quality natural rubber which provides superior resistance to cutting and gouging to load support and convey different type and size of material, from short to long distance and light to heavy load transportation of materials. These belts are mainly used in all the process industries to carry different materials such as fertilizer plants -super phosphate in lump and powder), cement plants-limestone, clay slacked lime, sand,cold clinker steel & power plant -coal,coke, ashes and crushed metallic ores stone crushing industries -granite & blue metal,crushed stone. Biomass power plant -biomass fuels, wood chips, paper bales, gravel, sized coke, glass industries-timber crushed glass, granite, all types of slacks, sandstones, chipping, quartz, stackers and reclaimers.

...more

Fire Resistant Conveyor Belt

Our fire resistant conveyor belts are perfect to prevent fire risks in coal mines and reduce the maintenance of conveyors, which are prone to be damaged by flame at the blast furnaces of iron works. Apart from this, these fire resistant belts also find usage in thermal power plants, mining industry, coal cleaning plants and other industries. fire-resisting conveyer belt can be classified into two grades: 1. fr grade � our range of fr grade conveyor belt is fire retardant. Resistance to flame propagation, extremely low burning rate. Suitable for surface application. 2. fru grade - our range of fru grade conveyor belt is fire retardant. Resistance to flame propagation, extremely low burning rate. Suitable for underground application features : � high tensile strength � flame-resistant � static-conductive � resistant to high heat & wear � resistance to the deteriorating effects of materials such as coal treated lightly with oil � capability to perform under extreme temperatures � high abrasion resistance � excellent low temperature flexibility

...more

Conveyor Idlers & Rollers

Heavy duty construction steel rollers & idlers with multi-labyrinth sealing to protect the bearings. Ideal for high capacity conveying and giving a longer service life, reducing belt ware and maintenance costs.

...more

Conveyor Head And Tail Drum Pulley

We are one of the highly acknowledged manufacturer of conveyor head and tail drum, which are fabricated with finest quality raw materials under the supervision of experienced professionals, who adhere to all internal quality norms while manufacturing the pulleys. Additionally, unparalleled performance, high durability, ability to work in adverse environment make highly suitable for fulfilling all requirements of many organizations and serving diverse industries. We are offering these pulleys throughout the market at industry leading prices. features: dust proof durability highly durable easy to maintain defect free range rigid construction resistant to abrasion resistant to corrosion less power consumption specifications: conveyor pulley are support to both side belt type of pulley: drive pulley & tail pulley pulley is making: pipe, shaft , its different size applications: road construction plant mining plant sugar plant lignite plant cement plant material handling plant

...more

Chevron Belts

Chevron belts with various cleat patterns, widths and heights are an excellent choice for high capacity conveying at steep angles, and prevent load slip or product roll back. The multi-v pattern with overlapping cleat design allows smooth belt travel over return idlers and increased conveyor capacity

...more

bucket elevator belt

One common method of elevating elevator buckets is attaching them to a belt. Belt is available in a variety of materials, cover thicknesses and grades selected to meet the specification application. Belt-type bucket elevators utilize a rubber belt. Common application of this type of belt is in the feed and grain industries, power plants & cement plants.

...more

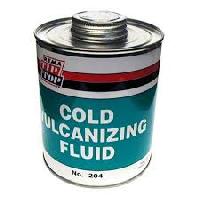

Conveyor Belt Jointing & Repair Services

Cold vulcanizing solutions offered comprise cold vulcanizing also known as non flammable cold vulcanizing solutions. Here, the contibelt 9000 offered is a black color, viscous liquid that has brushing viscosity. As a two component, room temperature curing synthetic rubber based adhesive, when catalyzed using appropriate amount of hardener, it yields high strength adhesion when bonding – • rubber to rubber • rubber to fabric • rubber to steel • rubber to pvc • urethane • fiberglass • concrete with contibelt 9000 formulated after extensive r & d efforts, we are able to successfully address diverse process needs of different industry sectors. Further, these cold vulcanizing solutions are also highly popular for applications involving - • conveyor belt jointing • pulley lagging • belt repair

...moreBe first to Rate

Rate ThisOpening Hours