Fire Hydrant System

Get Price Quote

* We Offer Fire Hydrant Valve, Single Oblique Outlet.body / Female Inst. Oblique Outlet (63mm Size) with Pull Out Type Lug Made of Gunmetal / Ss, 75mm N.b. Flanged Inlet, Spindle Made of Brass /ss and Hand Wheel Made of Cast Iron (is: 210), Complete with Abs / Pvc Blank Cap & Chain, Bearing Bis: 5290 Mark, Flange Dimension: O.d. 200mm, Pcd 160mm, Four 19m Dia Holes * Fire Hydrant Valve, Right Angle Type Single Outlet :body Made of Gunmetal, Is: 318 Ltb 2 Grade, 75mm N.b. Flanged Inlet, 63mm Female Inst. Right Angle Type Outlet, Spindle Made of Brass and C.i Hand Wheel, Complete with Abs Blank Cap & Chain, Bearing Is: 5290 Mark, Flange Dimension: O.d. 200mm, Pcd160mm, Four 19mdia Holes * Double Hydrant:fire Hydrant Valve, Double Individually Controlled Outlets. Body/ Female Inst. Outlets (two Nos. of 63mm Size) with Pull Out Type Lug Made of Gunmetal / Ss, with 100mm N.b. Flanged Inlet, Spindle Made of Brass / Ss , Complete with Abs / Pvc Blank Caps and Chains, Bearing Bis:5290 Mark, * Stand Post Type Fire Hydrant – Double / Single Outlet * M.s. Post with Flanged Inlet, with Double Outlets 80mm N.b. Flanged Diagonally Opposite, - Complete with Two / One Fire Hydrant Valve – Single Oblique Outlet, Material Gunmetal ( Is: 318 Ltb2 Grade), 80mm N.b. Flanged Inlet, Brass Spindle, 63mm Female Inst. Oblique Outlet as per Is: 903, Complete with Abs Blank Cap & Chain, Bearing Is: 5290 Mark, - Set of Nut Bolts and Gasket for Each Hydrant Will Be Provided. - Flange Drilling Dimension Will Be as per Ansi B 16.5 Class 150 * Fire Hydrant – Underground : Made of Cast Iron, 80mm N.b. Flange Inlet, Gm 63mms Male Round Threaded Outlet, with C.i. Cover Cap and Chain, Conforming to Is: 909 Type-2, Flange Dimension: O.d. 200mm, Pcd 160mm, Four 19mdia Holes (otherwise as Specified By Client)hydrant Key, Made Out of Al. Alloy * Pressure Reducing (controlled Pressure) Hydrant Valve – Made of Copper Alloy (is:318-ltb Gr.-2) – with 63mm Flanged Inlet Drilled as per Ansi B 16.5 Class 150 & Integrated 63mm Size Female Instantaneous Outlet, Brass Spindle, Cast Iron Hand Wheel, – Duly Hydro-tested At 21 Bar Pressure, Dully Painted – Fire Red Colour, * Pressure Restricting Valve : Made of Copper Alloy(is:318-ltb Gr.-2), Having 50mm Size Nh/nst/bsp (f) Threaded Inlet with 50mm Size Nh/nst(m) Threaded Outlet, Light Alloy Hand Wheel, Natural Finish * Stand Post Type Fire Hydrant – Four Outlet, 600 Mm High X 150 Mm (6”) Nb M.s. Post with Flanged Inlet, Having Four Outlets 75mm N.b. Flanged Type. Complete with Four Nos. Fire Hydrant Valve, Single Oblique Outlet Body, Female Inst. Oblique Outlet (63mm Size) with Pull Out Type Lug Made of Gunmetal, Is: 318 Ltb 2 Grade, 75mm N.b. Flanged Inlet, Spindle Made of Brass (is:319) and Hand Wheel Made of Cast Iron (is: 210), Complete with Abs Blank Cap & Chain, Bearing Bis: 5290 Mark, Set of Nut Bolts and Gasket for Each Hydrant Will Be Provided.flange Drilling Dimension Will Be as per Ansi B 16.5 Class 150.

Fire Hydrant System

Get Price Quote

Best Deals from Fire Hydrant Pumps

Fire Hydrant System

2,500,000 Per Unit

1 Piece (MOQ)

Fire Hydrant Pump System

500,000 Per Piece

Fire Hydrant Pump

Get Price Quote

We are leading manufacturer and supplier of Fire Hydrant Pump.

Fire Hydrant System

Get Price Quote

Hydrant Fire Fighting Pump

37,000 Per Piece

1 Piece (MOQ)

Fire Hydrant System

Get Price Quote

Fire Hydrant System

Get Price Quote

10 Piece (MOQ)

Fire Hydrant System

Get Price Quote

50 Piece (MOQ)

Fire Hydrant System

Get Price Quote

1 Unit (MOQ)

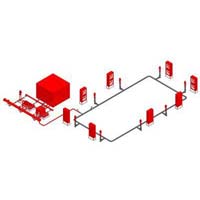

IS IT ALWAYS NECESSARY TO PROVIDE FIRE PROTECTION WITH FIRE HYDRANT SYSTEMS? Fire Hydrant Systems forms the basis, of Fire Protection Systems, without Fire Hydrant System a Fire Protection System cannot be called a Fire Protection System. It will be a superficial system. (With respect to large areas, in general). Fire Hydrant System installation is relatively easy. HOW DO FIRE HYDRANT SYSTEMS FUNCTION? A special well is dug, called "Fire Well", where water is stored throughout the year for 365days. This water well is connected to the pump room. From the pump room, there are two to three main pipes. These pipes form a network of pipe that cover the factory compound and the factory. The pump has the work, to continuously filling all the pipes connected with water under pressure. The pressure is nearly 7bar to 10bar. When a fire is seen by a person, he activates the hydrant system and points it in the direction of the fire. A very strong flow of water now, attacks the fire and the fire is eventually extinguished. The pump continuously pumps the water to maintain the system pressure. WHAT ARE THE ADVANTAGES OF FIRE HYDRANT SYSTEMS? Fire Hydrant Systems are very strong and can be used from medium to large sized fires. Fire Hydrant Systems, have a long range. Since the Fire Hydrant System is spread out, the fire hydrant can attack fire from different angles. This entire system requires low maintenance and virtually, does not leak water. Besides this, Fire Hydrant Systems have a long life. WHAT ARE THE DISADVANTAGES OF FIRE HYDRANT SYSTEMS? There are few disadvantages. The first is that it has to be manually activated. The flow of Fire Hydrant System is so strong that, there are two men required to hold the water hose. Fire Hydrant System may cause damage to the instruments or machines. Fire Hydrant systems are very popular and hence many, Clients search only for Fire Hydrant Companies or Fire Hydrant System Suppliers; but the important thing to understand is that it may not be the most efficient system.

Fire Hydrant System

Get Price Quote

Our payment procedures are well documented, legal, and safe. We provide our clients with numerous online and offline options for making purchases and make sure they are protected. We are instrumental in offering extensive range of products that is in compliance with the internationally accepted standards. Thus, the final products are of excetional quality.

Fire Hydrant Systems

100 Per Piece

fire hydrant systems dealers suppliers sellers distributors in Ludhiana Punjab India

Fire Hydrant Booster Pump

Get Price Quote

Fire Hydrant System

Get Price Quote

Fire Hydrant System Fire hydrant pump systems (also known as fire pumps, hydrant boosters, fire water pumps) are high pressure water pumps designed to increase the fire-hydrant-bottom fighting capacity of a building by boosting the pressure in the hydrant service when mains are not enough, or when tank fed. They can also be used in water transfer and irrigation applications. Hydrant Booster Pumps Fire Booster Pumpsets are available in diesel and electric drive configurations, assembled on a common fabricated base with pipework manifolds, valves, controls and accessories to provide a fully automated system complying with STANDARDS. Systems are engineered and fabricated in strict adherence to the relevant fire codes. Support services are provided from initial engineering assistance through to ON-SITE commission and after sales service. DIESEL HYDRANT BOOSTER PUMPS Also known as diesel fire pumps and diesel hydrant pumps. We offer complete assurance that all of our fire pumps are built and quality tested to meet safety standards, using industry-recognised pumps and engines.

Fire Hydrant System

Get Price Quote

Fire hydrant system The outlet is generally female instantaneous and male inst. outlet is available on request. Our hydrant valves are available in size range of 38mm to 63mm,

Fire Hydrant System

Get Price Quote

automatic fire hydrant system

Get Price Quote

10 Piece (MOQ)

Fire Hydrant System

Get Price Quote

We are one of the top-quality suppliers of Fire Hydrant System from Gurgaon, Haryana, India. Our range of Fire Hydrant System is manufactured using approved material and processed as per the international quality norms. While the Fire Hydrant System is easy to operate, it guarantees durability. We package the Fire Hydrant System safely and promise speedy delivery of the Fire Hydrant System to the clients.

Fire Hydrant System

Get Price Quote

Equipped with the exceptional machines and leading technologies, we are instrumental in offering the best in class products that are stringently packed under the supervision of experts. We are immensely accredited for delivering the orders within the stipulated time frame as we have the latest transportation facilities.