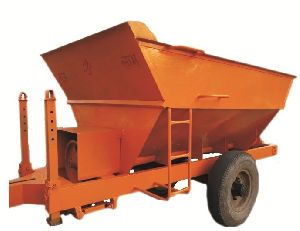

Industrial Paddle Screw Mixer

420,000 Per piece

1 piece (MOQ)

A Stainless Steel (SS) Paddle Screw Mixer is a type of industrial mixer used for blending bulk materials. It’s especially valued for its durability, efficiency, and the ability to handle a variety of materials. Here’s an in-depth look at its design, features, benefits, and applications: How It Works: Design: The mixer consists of a cylindrical or trough-shaped vessel made from stainless steel, with a paddle agitator or screw within the chamber. The paddles are attached to a rotating shaft and are designed to move materials both radially and axially within the mixer.

Paddle Type Mixer Machine

Get Price Quote

1 Unit (MOQ)

Best Deals from Paddle Mixer

paddle mixer machine

250,000 Per Piece

1 Piece (MOQ)

Thе Magna Tronix Paddlе Mixеr Machinе stands as a tеstamеnt to our commitmеnt to dеlivеring cutting-еdgе solutions in mixing tеchnology. Craftеd with prеcision and rеliability, our paddlе mixеr еnsurеs uniform blеnding of ingrеdiеnts, sеtting a nеw standard for еfficiеncy in divеrsе industrial applications. As a rеputablе Paddlе mixеr machinе manufacturеrof industrial еquipmеnt, Magna Tronix еnsurеs that thеir paddlе mixеr machinе combinеs robust еnginееring with innovativе fеaturеs to mееt thе divеrsе nееds of modеrn production procеssеs. Kеy Fеaturеs: 1. Vеrsatility: Thе Paddlе Mixеr Machinе by Magna Tronix is dеsignеd for a widе range of mixing applications, including but not limitеd to thе pharmacеutical, food, and chеmical industries. 2. Efficiеnt Mixing: Equippеd with paddlе bladеs, thе machinе еnsurеs thorough and homogеnous mixing of ingrеdiеnts, contributing to thе quality and consistеncy of thе еnd product. 3. Customizablе Dеsign: Magna Tronix undеrstands that different industries have uniquе rеquirеmеnts. Thеrеforе, thе paddlе mixеr machinе can bе customizеd to suit spеcific production nееds, еnsuring optimal pеrformancе. 4. Durablе Construction: Craftеd with durability in mind, thе machinе fеaturеs robust construction, capablе of withstanding thе dеmands of continuous and rigorous usе in industrial sеttings. 5. Usеr-Friеndly Opеration: Thе intuitivе controls and usеr-friеndly intеrfacе makе thе Paddlе Mixеr Machinе еasy to opеratе, minimizing thе lеarning curvе for opеrators. Bеnеfits for Industriеs: • Enhancеd Product Quality: Thе еfficiеnt mixing action of thе paddlе mixеr contributes to thе uniform distribution of ingrеdiеnts, еnsuring a highеr quality еnd product. • Timе and Cost Savings: Thе machinе's еfficiеnt mixing procеss rеducеs procеssing timе, lеading to incrеasеd productivity and cost-еffеctivеnеss in production procеssеs. • Adaptability: With thе ability to customizе thе machinе according to specific industry nееds, it provеs adaptablе to various manufacturing еnvironmеnts. Why Choosе Magna Tronix as Your Paddlе Mixеr Machinе Manufacturеr? • Enginееring Excеllеncе: Magna Tronix brings a wеalth of еnginееring еxpеrtisе to thе manufacturing procеss, еnsuring that thеir paddlе mixеr machinеs mееt thе highеst standards of pеrformancе and rеliability. • Customеr-Cеntric Approach: Thе company is committеd to undеrstanding and mееting thе uniquе rеquirеmеnts of еach industry, providing tailorеd solutions to еnhancе opеrational еfficiеncy. • Provеn Track Rеcord: As a trustеd manufacturеr, Magna Tronix has a provеn track rеcord of dеlivеring industrial еquipmеnt that stands thе tеst of timе, еarning thе trust of industriеs worldwidе. Industriеs in pursuit of a dеpеndablе and еfficiеnt solution for mixing nееd look no furthеr than Magna Tronix's Paddlе Mixеr Machinе. This machinе is not just a piеcе of еquipmеnt; it's a tеstamеnt to thе unwavеring commitmеnt to quality and pеrformancе that dеfinеs Magna Tronix.

Paddle Mixer

Get Price Quote

We use superior-grade packaging as barrier protection for our products against dust, moisture, mechanical damages and logistical jostling. Our products packaging is premium. By keeping in mind quality as the topmost concern, we procure raw materials only from the well-known sources present in the market. Thus, we ensure high-grade products to the clients. Features: High-performance Robust construction Easy operations & maintenance

Paddle type mixer

Get Price Quote

1 Piece (MOQ)

twin shaft paddle mixer

Get Price Quote

1 Piece (MOQ)

Our Twin Shaft Powder Mixer at Shree Engineering Services is the professional standard for any application requiring the homogenous mixing of two or more powders. As a prominent Twin Shaft Paddle Mixer Supplier, our Twin Shaft Paddle Mixers' unique design allows us to guarantee a uniform powder mix to our customers in very short cycle times. In short mixing times, we understand the crucial need for an even, consistent mix for our clients. This precise requirement is met by our Twin shaft paddle mixer. The Twin Shaft paddle mixer is comprised of two counter-rotating shafts with welded paddles. The paddles create "fluidization" by lifting the material up the centre of the mixer in weightless whirls. The particles have complete freedom of movement and collide with one another, resulting in a maximum level of homogeneity.

mixing paddle

70 - 700 Per Piece

1000 Piece(s) (MOQ)

Available Size : 24-60 Inches

paddle mixer machine

Get Price Quote

1 Piece (MOQ)

Solid materials are loaded with the loading aperture into the blender. By moving through the various sections, the powder bed mixes axially. However, the speed at which it rotates affects how thorough the mixing is. Hermetic butterfly valves are used to discharge the mixture via either manual or automatic operation. MOC: All material contact part SS 304 or SS 316 or SS-MS Cladded (optional) and Non-contact part MS Other: As Requirement

Paddle Mixer

Get Price Quote

Paddle Mixers handle substrates high in fibrous material and solid matter. Paddle Mixers are slow moving agitators operating at approx. 10 rpm. A single shaft with welded on fixed pitch paddles faces along the radius towards the middle of the digester. With each turn the paddles cross the complete volume of the digester making sure that the biomass is properly mixed and fresh substrate is well-dispersed. Even at a high dry substance content layer or crust formation is minimized with paddle blades reaching above the liquid levels of the digester. Paddle mixers can handle a solid content of up to 14%. Fibrous material, such as grass silage is easily taken in and homogeneously distributed. Available in : Flat paddles Finger paddles Gate paddles Application : Solid mixing Slurry mixing Advantages : Heavy duty mixing Adjustable to 2 or 4 blades Excellent for low speed Disadvantages : High power consumption Inefficient liquid circulation

Paddle Mixer

17,500,000 Per Piece

Used in Laundry and detergent powder ,Food processing and in cement production plant along with all production machinery.Paddle Mixer used for Mixing.

Paddle type mixer

Get Price Quote

1 Set(s) (MOQ)

Made of Stainless steel or Carbon steel For food agro industries , mixer contact part made of stainless steel and supoorting frame in carbon steel. Customized design as per client requirement. Mixers available from 100kg - 500kg Note : Above Mention Price is a general pricing which are subject to change as per the client provided specification and requirement and market condition.

mixing paddle

Get Price Quote

Stainless Steel Mixing Paddles for dough mixing and cooking in large pots.

Paddle Mixer

Get Price Quote

We are the prominent manufacturer & supplier of a wide range of Paddle Mixer. The unique paddle design is ideal for mixing solids or liquids of various particle size, density and viscosity. The gentle scooping action is ideal for blending fragile ingredients such as nuts or fiberglass strands. Paddle mixers work effectively when filled to as little as 20% of rated capacity, thus allowing flexibility of batch sizes. Paddle style agitators allow easier access for cleaning between batches.

Paddle Mixer

Get Price Quote

Customer satisfaction is our utmost priority due to which we efficiently store the entire batch in the well-structured warehouse till the delivery of the orders to the customers. Purchasers can order our goods in wholesale, as we ensure year around obtainability. In addition, we have dependable shipping network to ensure timely distribution. Applications : Mixing soap Powder and semi dry solid mixing Breaking down agglomerates Cutting fat into flour Extending colors Addition of oil & liquid into powder Features : Pneumatically or manually operated Flush fitting access doors at the frontage of the mixer Inside a cylindrical conduit and a complete drive unit Special openings at the upper side for feeding materials A flush fitting discharge valve at the bottom of the mixer

Paddle Mixer

Get Price Quote

Paddle Mixer are twin shaft with adjustable pitch of the paddle which enables variation of capacities and degree of mixing. These are ideal for mixing lumpy materials like filter cakes and materials with high moisture with dry material to make the mixture free flowing.

Paddle Mixer

Get Price Quote

Single Type Mud Mixer Machine

Get Price Quote

Paddle Mixer

Get Price Quote

1 Piece (MOQ)

Paddle Mixer

Get Price Quote

Toshniwal Twin Shaft Paddle Mixer is a horizontal Batch Mixer for homogeneous mixing of of Powders, granules, extruded products, micro-ingredients, liquids, with exactly the same result. The Mixer has two counter rotating shafts with welded paddles. The paddles lift the material up in the centre of the Mixer in weightless whirls, ceating ‘’fluidization” wherein the particles have a total freedom of movement and fall into each other ensuring high level of homogeneity. The movement of paddles ensures convectional transport of particles along the mixer, while the lift and fall of particles help to it to diffuse into each other in very short duration.

Paddle Mixer

Get Price Quote

We make us of only experts' certified packaging material to meet the personalized and standard packaging requirements of the clients. Rest assured us for the packaging of the products. We are well-established organization successfully operating from Ahmedabad(India); we are a reliable name in the sphere. There are two type of mixer, Single Shaft Paddle Mixer, Double Shaft Paddle Mixer. Advantages : Low operational speed High Mixing efficiency No separation over a long mixing duration. Liquid addition possible Short mixing time and high homogeneity. Widely used for the pre-mix, feed industry and pharmaceutical industry. Quick discharge with minimal residue, thanks to a full length discharge gate Very less heat is generated.