Plastic Recycling Machine

Get Price Quote

We are the exporter and supplier of this products.

Double shaft Plastic scrap crusher Machine

500,000 - 1,000,000 Per piece

1 piece (MOQ)

Best Deals from Plastic Processing Machinery

LDPE Extrusion Machine

Get Price Quote

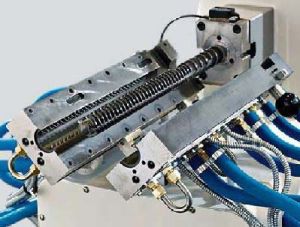

Single Screw Reciprocating Extruder (PCS 46)

225,000 Per set

1 set (MOQ)

Relying on our know-how in the industry gained over years, we, as a Manufacturer and Supplier of Single Screw Reciprocating Extruder (PCS 46) have put us in the top band of the industry. It can be easily cleaned in a short time span. Our customers can also save their costs as it consumes less heat and power. It also takes lesser time and energy in case of a power failure. Advantages No need of additional lab extruder for product development, shade / color matching, RM testing Easy & fast cleaning due to short length, easy & fast cooling due to water heating system Wide range of products can be produced on single screw extruder - like PU, PTFE, low curing, etc. Running cost is low as compared with Twin Screw - Low Power, Low heating cost Small batches can be easily possible Thorough cleaning is possible in small time span. Consistence product Quality possible due precise Temp Control, no problem of jamming, no problem of product deletion Low maintenance cost as compared with Twin Screw Modular design of Screw Elements to felicitate the change in kneading / feeding lengths Thru Cooling Shaft - ensures the controlled process temp. / easy cleaning of screw & avoiding deletion in the barrel. process length is much less than the Twin Screw extruder, ensures less residence time for product. machine is easy to operate If power failure occurs - takes less time / less energy for restart Due close loop heating cooling system - load on chilling gets reduced drastically Disadvantages Fine processing is limited to certain extent ( in case of rejection processing) requires extra care to be taken Spares cost is high ( but / kg cost is low as compared with twin) Thorough Cleaning is time consuming / you may need to keep spare set of Screw Shaft

Plastic Extruder with Force Feeder

Get Price Quote

Plastic Recycling Machine

Get Price Quote

Plastic Granule Recycling Machine

Get Price Quote

1 Piece (MOQ)

HDPE LDPE Extrusion Machine

Get Price Quote

1 Unit (MOQ)

ADVANCE FEATURES: High Performance Main Motor AC Inverter driver is designed for energy saving as well as minimum maintenance. Helical Gear Box for low power consumption. Grovefeed Screw Barrel for low wear, high mixing, homogenity and high output. Candle type screen changer which minimuzes material wastage. Specially designed air ring ensures uniform air supply and maximum supply stability. Auto air refilling system for minimized material wastage. Takeup roller with pneumatic system for easy operation. Winder surface type with torque motor for best winding. Special compact design for space Saving.

Plastic Extrusion Machine

500,000 Per Piece

1 piece (MOQ)

Shuttle Type Rotomoulding Machine

Get Price Quote

The Rotomoulding Plant with Multi Arm Shuttle machine Series CP is composed of Moulding Chamber ( Indexing )with attatched combustion chamber , High Velocity cooling fans with Fog heads , Arms conveyors .& Control Electric Panel. Shuttle Type Rotomoulding Machine is easy to install and promises optimum performance at low operating cost. Salient Features Aerodynamic Oven Designed for maximum hot air impingement against the molds and feature counter-convection air flow to help even heating throughout the chamber area. Moulding chamber made of metallic double wall frame, thermically insulated with high density rock wool. Burner (two stage) placed at the combustion chamber, heats the whole moulding chamber uniformly and keeps steady the process temperature recordings performed by thermic feelers installed in the moulding chamber. Centrifugal Fans with duct and louvers for adjusting hot air direction for correct distribution of the material inside the mould . Independent high velocity blowing fans for each Arm mounted on steel frame for uniform cooling. Turret made of heavy-duty steel tube construction Smooth conveyor movement on straight track. Floor area provides two process stations.

HDPE Plastic Drum Blow Molding Machine

650,000 Per

1 Piece (MOQ)

EPS Cup Making Machine

Get Price Quote

EPS Cup Making Machine, a high-end cup making machine aims to take productivity of a unit to a next level. Developed with revolutionary technology, EPS Cup Making Machine uses efficient working principle for rendering best services. Our EPS Cup Making Machine is greatly demanded for its remarkable workability and longer service life. Application : EPS Cup Making Machine facilitate EPS raw material to expand to the required density Features : Strong M.S. structure S.S. shell 5-Hp. Motor with reduction Gearbox 2- Hp. Motor with High flow Blower EPS raw material Feeding screw device with 1-Hp. Motor & Hopper Parameter control : All manual operation Material Expander Material Expanded Jar Size : Φ 800 *H1200 (mm) Steam Pressure : 0.3-0.6MPA Air Pressure : 0.3-0.6MPA Foaming Ratio : 20~50 Foaming Error (Grain) : �10% Output : 50-160KGS/H Power Consumption : 3KW/H External Power Supply : 3-phase 380V 50Hz Machine Size : 1400mm*800mm*2500mm Machine Weight Approx. : 1.2T Dryer Output of Air-drying :150-200KGS/H Power : 6.6KW Machine Size : 4000mm*800mm*1000mm Central Feeding System Blower Power : 3 sets, 2.2KW Bigger Hopper : 2 pcs,3000mm*3000mm*3000mm Small Hopper : 2 pcs,800mm*800mm*500mm

Automatic Roto Moulding Machine

350,000 Per piece

1 piece (MOQ)

CSFprimus Series Filter Screen Changer

Get Price Quote

Patented Rotary Filtration System with large active screen area and two working positions.Continuous and fully-automaticPatented rotary filtration system with large active screen area and two working positions. The filter disc is divided into two zones, which can be alternately moved into the melt channel. On request (e.g. for batch or roll changes) the positions and thus all screens in the melt channel are automatically changed. The melt flow is not interrupted, so that downstream components do not have to be restarted afterwards. Filter elements can be replaced at any time between two changes.The advantages of CSFprimus screen changers Compact-The small and compact design of the Rotary Filtration Systems makes simple and cost-efficient integration possible even in a very confined space. Sturdy-The metallic sealing system is highly wear-resistant. It guarantees leak-free operation even with low viscosity melts up to 500 bar. Streamlined-The rheology of the melt channel and the inner parts of the screen changer can be individually adjusted to the specific requirements. Uncomplicated-A screen change can be carried out automatically at any time without interrupting the melt flow. In case of a change, all screens in the melt flow are completely exchanged. Such a change should preferably take place during roll/batch changes. If more frequent changes are required during the production batch, a pressure-constant system (SFneos, SFXmagnus or RSFgenius) should be used. The filter disc is divided into two filter segments which can be alternately introduced into the melt channel. The change is done fully automatically. The system is driven hydraulically or pneumatically.The segment, which is not located in the melt channel, is completely accessible, so that the operating personnel can replace the filter elements at any time between changes. On request, a version with removable breaker plates is also available, so that even demanding colour changes can be carried out in the shortest possible time.During the change itself, the melt flow is not interrupted, so that downstream components generally do not have to be restarted after the change.

Plastic Storage Mixer

Get Price Quote

1 Piece (MOQ)

Plastic Extrusion Machine

Get Price Quote

1 Piece(s) (MOQ)

Plastic to oil Plant

Get Price Quote

Plastic Waste is treated to produce Low Density Oil (LDO), Carbon and Liquified Petroleum Gas (LPG). LDO can be further refined to a better quality fuel like Petrol & Diesel.

Plastic Waste Crushing Machine

150,000 - 800,000 Per Piece

1 Piece (MOQ)

plastic crusher machine manufacturers

230,000 - 240,000 Per piece

1 piece (MOQ)

Plastic bottle shredder machine, plastic shredder, shredder machine, bottle shredder machine

Plastic Waste Recycling Extrusion Line

1,850,000 Per Piece

1 unit (MOQ)

Shreeji plastomech pvt. Ltd. Is leading manufacturer plastic waste recycling extrusion line plant in india.