SFXmagnus Series Filter Screen Changer

Get Price Quote

The SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application.Constant pressure and process consistency-The SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application. This series is characterized by an extra large active screen surface area, its compact design, as well as extremely easy operation. Screen changes do not have any influence on the product quality.The advantages of the SFXmagnus Filtration System Economic-The extra large active screen surface area in relation to the screen changer size allows a unique economic efficiency of the SFXmagnus. The return on investment is realized within a very short period of time. Constant-By assuring a consistent active screen area, the pressure can be kept nearly constant during the whole production process. Melt temperature, viscosity and throughput are also free of variations at any time. Constant quality of the final product is guaranteed even during screen changes. Quality-Thanks to the optimized melt channel flow path and completely airtight encapsulated design, the requirements with regard to the purity and quality of the melt can be achieved and permamently maintained. Streamlined-The optimized rheological design of the melt channel flowpath ensures a minimized residence time (< 1 minute) thus ensuring for example fast material or color changes. Straightforward-The control system informs the operator in advance of an upcoming screen change. The screens can be changed quickly and easily and without any influence on the process or pressure consistency. Compact-The remarkably compact size of the SFXmagnus allows an easy and inexpensive integration even within limited space. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low. Mode of operationWhen a pressure increase upstream of the filter is registered, the filter disk is indexed automatically by means of a pneumatic or hydraulic drive. The active screen area is always kept constant and the pressure upstream of the filter increases only slightly during the whole production process. After the cavities have passed through the melt flow, the screens can be removed without disturbing the production process.DesignThe filter disk – on which the screen cavities are located in a ring pattern – is completely encapsulated by the two filter blocks. Screens can be inserted into the cavities by opening a small hatch door giving access to the cavities. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.

Hydraulic Screen Changer

1,250,000 Per Piece

1 piece (MOQ)

Best Deals from Screen Changer

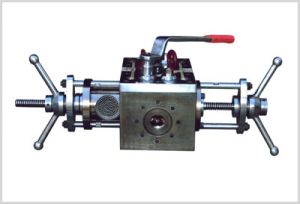

MANUAL LEVER SCREEN CHANGER

45,000 - 90,000 Per Piece

Capitalizing on our sophisticated quality analysis facility, we have emerged as the distinguished Supplier of the Manual Lever Screen Changers from Gujarat, India. Compliant with the industry stipulated standards, these Screen Changers withstand adverse temperature conditions and still perform unfailingly. We can even arrange for the Manual Lever Screen Changers in customized specifications, on special request. Stay assured of reasonable pricing.More About Manual Lever Screen Changers : The manual screen changer of these Filters is a low-cost filter solution for the plastic-rubber extrusion, applied best to applications where line stops occur on a periodic basis. The filter can be changed during this shutdown without effecting production. A typical application is blown film, where the die must be cleaned prior to the screen clogging. Models : 30,40,50,65,75,90,100 Output : 40 to 400 kgs per hr Heating : 0.6 to 6.0 KW Special Features : Round breaker plate design with maximum melt filtering area Melt filter cavity as per client requirement Leakage proof Screen Changer due to close tolerances Imported sealing design for Input & output melt flow path Smooth handle assembly design for changing filters from one station to another Melt Temperature measuring provision Melt Pressure measuring provision for safe & in time operation Advantages : Simple & quick operation Simple & quick filter changing Low heating load consumption Saving labour Low maintenance cost Application : Suitable for variety macroviscosity melt of extrusion line. Including: Blowing film Lab extrusion Food extrusion Chemical extrusion Non-woven cloth extrusion EVA, thermo sol and self adhesive label,(PSA) material Sheet extrusion Extrusion coating Tubeprofile extrusion Compounding extrusion Cable extrusionFlexible pipe extrusion

Platen type screen changer

Get Price Quote

We are manufacturing screen changer for plastic processing plant . This screen changer is suitable tor pet processing , box strapping plant, monofilament plant. Etc.

Hydraulic Screen Changer

Get Price Quote

We are an eminent Hydraulic Screen Changer Manufacturer, Supplier and Exporter from India. The Hydraulic Screen Changer offered by us is ideal for high pressure and high output. Hydraulic Screen Changers are double stage for easy and quick changing of the screens during production. Further, these Hydraulic Screen Changers are equipped with graphite Teflon sealing for zero leakages. We have designed Hydraulic Screen Changer in such a way that it helps in continuous changing of screens on line without disturbing the production. Also, all the parts are closely monitored and control part is handled by hydraulic pack with a safety valve. Features

Hydraulic Screen Changer

Get Price Quote

Our rapidly growing organization is busy in offering a premium quality Hydraulic Screen Changer that is available in numerous sizes.

Hydraulic Screen Changer

Get Price Quote

Hydraulic Screen Changer

Get Price Quote

We are an eminent Hydraulic Screen Changer Manufacturer, Supplier and Exporter from India. The Hydraulic Screen Changer offered by us is ideal for high pressure and high output. Hydraulic Screen Changers are double stage for easy and quick changing of the screens during production. Further, these Hydraulic Screen Changers are equipped with graphite Teflon sealing for zero leakages. We have designed Hydraulic Screen Changer in such a way that it helps in continuous changing of screens on line without disturbing the production. Also, all the parts are closely monitored and control part is handled by hydraulic pack with a safety valve. Features Easy process Quick functioning Zero leakages Continuous changing of the screens Trouble free performance Available With Liquid nitrogen cylinder operated system

Discontinuous Screen Changer

Get Price Quote

We bring forth Discontinuous Screen Changers in two types- Manual and Hydraulic Platen each one of which incorporates the most robust design providing reliable and leak-free processing. The Manual Screen Changer is suitable for virtually any extrusion process that can afford a momentary shutdown to change screens and offers the most cost effective method of filtration available. Features : Our manual Screen Changers was designed and precisely made using special Seals, insuring leak-free operationBuilt-in heaters gives fast heating and helps in retaining temperatureEnsures quality processing, high product quality and reduced waste materialsOur Screen Changers are very compact & easy to install with Low Maintenance and low cost spare partsOur Design is operator friendly for easy operationIt is most reliable and durable, as it is made by a steel body for long life. The special chrome and nickel plating gives high protection against wear out

Plunger Screen Changer

Get Price Quote

Aarohi enterprise brings Plunger Type Manual Screen Changer for the processing of thermoplastic extruders. The company was established in 1995 and progressing in the plastic industries from last 20 years. Aarohi offers a broad range of international quality screen changers. Today the company is also having a major customer of screen changers. This screen changer is manually operated. Changing cycle is 2 to 3min. This model is also available with a Hydraulic System if required. Accessories provided extra: Special adaptors for die and barrel side as per your requirement. Spare breaker plate and heaters. Benefits of manual screen changer : It filters the plastic material and removes impurities there by preventing damage to the die. Quality of the final product remains good through the process. Leakage problem gets eliminated. Maximum utilization of plant becomes possible. Increases the life of mesh and hence saves money. Easy to operate. Reduces the idle time. Used for: Sheet plant Pipe Plant Lamination Plant Tape plant Film Plant Blow Molding Extrusion Plant Blown Film Plant Multi Layer Blown Film Plant

Continous Screen Changer

Get Price Quote

Screen Changer in Operation : All Valve are opened with both lines on running position. Close Valve 1 & 2 slowly and remove the plunger by puller and replace the mesh. The plunger placed in body by puller and tightened both of the plunger than open Valve no. 1 as marked so empty chamber of plunger will fill up the material without disturbing the flow. Then open Valve C for removing inside air and clean the material should come out from this Valve and open Valve No. 1 fully. And open Valve No.2 for output than close Valve C. This is again same 2 line working condition. Accessories : Adaptors for mounting the screen changer i.e. die & barrel side. Spares – Heaters, Screen packs. Application & Usage : Necessary to use screen changer for filtering the plastic material. Leak free design. Filter mesh change without stopping the extruder machine. Final product will be consistently good. 100% production without stopping plant. Advantages : Max. exploration of line due to without stop the plant. Elimination of scrap. Very easy operation. No. wastage of material.

Hydraulic Screen Changer

125,000 Per Piece

Lamination Plant, Sheet Plant, Filler Plant, Master Batch Plant, Pipe Plant, Recycling Plant, all types of extrusion plant etc.,

Screen Changer

Get Price Quote

We are one of the prominent manufacturers and suppliers of a technologically advanced gamut of Plastic Screen Changer. These Hydraulic Plastic Screen Changers are designed and developed as per the established industry standards using qualitative raw materials to ensure optimum functionality standards. To attain complete client satisfaction, we offer these Plastic Screen Changers in numerous specifications and at most nominal prices. This product is one of the most sort after products in our repertoire due to its high quality.

Screen Changer Machine

65,000 Per Piece

Extruder Screen Changer

Get Price Quote

Extensively used in the filtration of plastic material during the process of extrusion, our Extruder screen Changer assists in changing the melt filtration screen with utmost efficiency without any interruption in production. Ideal for continuous filtration and back flush, our premium range of Plastic Extrusion Screen Changer is capable of eliminating any contaminates from the final product. As one of the leading Manufacturers, we meticulously develop this Extruder Mold Screen Changer to meet the customers� requirements. Besides, these Screen Changers also ensure higher output and fine filtration. Features :- Suitable for continuous filtration and back flush. Ensures high outputs and very fine filtration Sizing, selection and training are all very critical issues for the successful installation and operation of these systems.

Screen Changer

Get Price Quote

M.AJAY offer Hydraulic operated continuous screen changers specially designed for Plastic reprocess industry. These Screen changers are designed for changing contaminated screens without stopping the plants resulting in higher productivity and minimum waste generation. M.AJAY offer models suitable for 40 kgshr plants to 500 kgshr recyling plants. Two step gas venting system to eliminate bubbling.Reduced pressure during material filtration which upgrades productivity.

Extruder Screen Changer

130,000 Per Piece

1 Piece (MOQ)

Hydraulic Screen Changer

128,000 Per Piece

1 Piece (MOQ)

Hydraulic Screen Changer

Get Price Quote

Our company packs the entire range of products with superior-grade packaging material that is nontoxic and recyclable. Furthermore, the packaging prevents damage and ensures the product is kept safe. By following a strict selection process, we source the entire range of raw materials from the certified vendors. Thus, we make sure that our finished goods will be flawless. Hydraulic Screen Changer has a lightweight body, which is extremely easy to operate and is available in a quality packaging.

Screen Changer

180,000 Per Piece

Screen Changer

Get Price Quote

In plastics extrusion, having the right screen changer for your material’s filtration requirements can make the difference between profit and loss. Parkinson Technologies’ line of Key Filters products offers custom engineered solutions and turnkey services to meet melt filtration needs for thermoplastic materials.

Hydraulic Screen Changer

Get Price Quote

Hydraulic Screen Changer, Stretch Film, Shoe Cover, Plastic Woven Sack

Screen Changer

Get Price Quote

Screen Changer, printing machine gear, printing machine spare parts

Hydraulic Screen Changer

Get Price Quote

Hydraulic Screen Changer, hydraulic coining press, Hydraulic Brake Press

screen changers

Get Price Quote

Vishva Exim is one of the prominent organization engaged in manufacturing and supplying a wide range of screen changers in India.

Hydraulic Screen Changer

Get Price Quote

Hydraulic Screen Changer, footwear machinery, coolant mixers

Hydraulic Screen Changer

Get Price Quote

Hydraulic Screen Changer, Mould Clamps

Screen Changer

Get Price Quote

Screen Changer, Slitting Cutter, Rotary Cutter, Plastic Processing Machinery

Hydraulic Screen Changer

Get Price Quote

Hydraulic Screen Changer, Dispersion Kneader, Pelletizing Lines

screen changers

Get Price Quote

screen changers, plastic processing machine, Pelletizing Line