vibrating motors

Vibrating motors are robust, reliable, high loadable quiet running and does not need any maintenance. Because of vast industry experience you will find a wide range of vibratory motors that is involved in manufacturing, exporting, and supplying. You should remain in sync with ever changing demands of customers. You should remain engaged in designing robust designed vibrating motor. The vibrating motor is manufactured using pure copper wires and approved components.Various manufacturers adhere to industry standards to assure high demand and supply. Many manufacturers supply vibrating motors and can be approached either through the Internet or can be surfed online.

...more

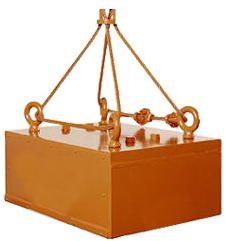

Suspension Magnets

Suspension magnet are designed to extract occasional tramp iron from the product stream by a conveyor belt or vibratory feeder. The magnet above a conveyor is placed at the right angle for optimum extraction. The suspension magnets are designed for the extraction of occasional tramp iron from the product steam conveyed by the conveyor belt.A suspension magnet can be suspended from the traveling trolley that can be moved away from the conveyor to be cleaned manually. Electro suspension magnet consist of aluminum or copper would coils immersed in the transformer oil. All electro suspension magnet comes along with control panel. The manually cleaned magnets should be provided with the stripper mechanism and no power consumption as well as virtually maintenance free.The magnets can be supplied with copper wound coils immersed in the transformer oil. These suspension magnets are available along with control panel. You simply need to suspend the magnet over the conveyor or over the head pulley. When the magnet surface starts to fill, swing the magnet away from conveyor and power can be cut in order to release the attracted metal.

...more

suspended magnets

Suspension magnet are designed to extract occasional tramp iron from the product stream by a conveyor belt or vibratory feeder. The magnet above a conveyor is placed at the right angle for optimum extraction. The suspension magnets are designed for the extraction of occasional tramp iron from the product steam conveyed by the conveyor belt.A suspension magnet can be suspended from the traveling trolley that can be moved away from the conveyor to be cleaned manually. Electro suspension magnet consist of aluminum or copper would coils immersed in the transformer oil. All electro suspension magnet comes along with control panel. The manually cleaned magnets should be provided with the stripper mechanism and no power consumption as well as virtually maintenance free.

...more

scart cable

The Scart rubber is also known as Euro Connector that make the positive difference in picture and sound quality. Quality scart cables run from moderately priced to quite expensive also the most modest upgrade that generates amazing results.Based on scart rubber you should use components to optimize performance. The bare copper shielding protects against signal loss and allows you to install the cable into correct inputs and outputs. Rubber strain relief allows you to provide the secure and provide flexible juncture between the cable and plug.

...more

needle metal detector

The electronic instrument that identifies the availability of metal at the nearest place. Such detectors are beneficial in finding the metal that is hidden within the objects or the metals are decayed underground. If the sensor is placed near a metallic piece you will come to know about it because of change in tone of earphone or the needle moves on indicator. Generally, the device provides the indication of distance. The nearer the metal, tone will be higher in the earphone or the needle moves higher.Another common type are stationary walk through that is used for security screening. The simplest form of the metal detector comprise an oscillator generating an alternating current that transfers through a coil generating an alternating magnetic field.

...more

Hydraulic Oil Filters

The hydraulic oil filters are used to clean dirt and other particles from fluid in a hydraulic system. Such a filter is used to remove such particles and clean the oil on a regular basis. The performance of every hydraulic filter is measured on the basis of the efficiency depicted in removing contamination. You will find that almost every hydraulic have more than one hydraulic filter.Various types of hydraulic oil filters are suction filters, pressure filters, return line filters, bypass filter systems, fillers and breathers, and filler elements. The general features of hydraulic oil filters are low cost, grade of filtration, and equipped with bypass check valve.

...more

hydraulic clamp cylinders

Clamp cylinders are used to clamp milling and drilling tools in mineral and ore industry. These clamp cylinders use pneumatic mechanism for operations and are filled with compressed gas to move the piston and hold it firmly in one place. Thus a great amount of force is exerted that holds tools in their apt position.One of the major concerns related to the use of clamp cylinders is the compressibility of a gas. It has been observed that the compression on the cylinder that is further applied by the gas in it due to load may mess with the precision of the mechanism. This phenomenon has been observed most prominently in vertical load bearing where the entire load in on the cylinder. Although studies have shown that the pressure on the cylinder is not as menacing. Thus quality manufacture and maintenance of clamp cylinders is quintessential.

...more

Hydraulic Clamp

Clamp cylinders are used to clamp milling and drilling tools in mineral and ore industry. These clamp cylinders use pneumatic mechanism for operations and are filled with compressed gas to move the piston and hold it firmly in one place. Thus a great amount of force is exerted that holds tools in their apt position.One of the major concerns related to the use of clamp cylinders is the compressibility of a gas. It has been observed that the compression on the cylinder that is further applied by the gas in it due to load may mess with the precision of the mechanism. This phenomenon has been observed most prominently in vertical load bearing where the entire load in on the cylinder. Although studies have shown that the pressure on the cylinder is not as menacing. Thus quality manufacture and maintenance of clamp cylinders is quintessential.

...more

Crusher Spare Parts

A jaw crusher is used for breaking large objects into smaller particles. Jaw crushers achieve this by imparting compressive force on objects. The mechanical pressure for crushing is achieved by two jaws of the crusher. One of the jaws is fixed and the other is moves in a harmonic motion. A jaw crusher comprises of a pair of vertical jaws. The jaw that always remains stationary is called fixed jaw and the jaw that facilitates movement is called swing jaw.A jaw crusher’s mechanism may be compared to that of a class II lever. A jaw crusher can be deemed as a vertical nut cracker. Crushing chamber, the cavity between the two jaws, is where the substance that needs to be crushed is placed. The movement of the swing jaw is kept very small so that a large particle does not simply escapes without being crushed to smaller parts. A flywheel is mechanically attached to the swing jaw which gives it a rhythmic motion as well as the inertia.

...more

Ceramic Pulley

Pulley lagging rubber is supplied by the local distributor or pulley manufacturer. For efficient and economical conveyor operation proper pulley lagging is in the integral detail. Some of the key benefits of pulley lagging rubber are:Extends the life of the key conveyor components,Reduce wear from abrasive materials,Protect belt slippage by enhancing the coefficient of friction between conveyor belt and pulley,Develops the self-cleaning action on pulley surface and protect the transported bulk material

...moreBe first to Rate

Rate This