consistency transmitter

Get Price Quote

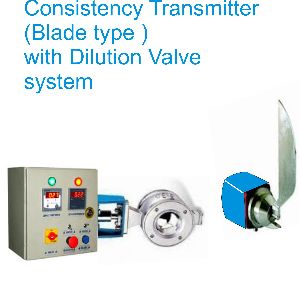

The consistency blade type transmitter measures consistency by sensing the "shear force" on a static blade in the stock stream. The size and shape of the blade is designed to compensate for small flow variations. This gives higher accuracy than traditional linear response curves because it adjusts for higher sensitivity at low consistency and lower sensitivity at higher consistency. This force causes the sensor blade to pivot; the amount of movement is proportional to the force needed to separate "shear" the fibers. The sensor blade is connected to a differential capacitor system. This non-contact device measures the movement and produces a variable voltage that is proportional to consistency. Thus "shear force" is converted into a voltage. This voltage is fed into a PID module. The module converts the voltage into a 4-20 mA signal. By utilizing a look up table, the nonlinear consistency sensor voltage is converted to a linear 4-20ma output. The module communicates via protocol on the 4-20 ma signal wires. Span, upper & lower range values and other variables can be adjusted using a standard hand held communicator.Features : Blade transmitter for all pulp furnish. No moving parts, only the blade is in touch with process. Digital display of set point and actual consistency. Pre calibrated for different type of stock to match any furnish. Microprocessor based controller read consistency 2% upto 10%. Main parts of consistency regulator. Consistency transmitter (blade) Consistency transmitter controller PID Controller Dilution Valve Controller with Dilution valve (size 50 mm to 75 mm) Dilution valve controller

consistency transmitter

Get Price Quote

50 Piece(s) (MOQ)

Best Deals from Consistency Transmitters

consistency transmitter

Get Price Quote

consistency transmitter, motorised basis weight valve