Conveyor Pulley Lagging Service

Get Price Quote

Waidhan group offers lagging of conveyor belt pulleys by cold & hot vulcanizing process. We have installed a large autoclave for pulley lagging by hot process. The autoclave can accommodate pulleys upto 2000mm diameter and face width upto 3000mm. Pulley lagging by cold vulcanizing is done without removing the pulley from the conveyor structure thus, reducing the installation cost and downtime using in-house cold vulcanizing cements and lagging sheets.

Pulley Lagging Rubber Sheet

Get Price Quote

5000 Meter (MOQ)

Best Deals from Pulley Lagging Rubber Sheets

Pulley Lagging Rubber Sheet

720 - 2,400 Per Meter

50 Meter (MOQ)

Rubber Pulley Lagging

Get Price Quote

Our organization has all the essential logistic resources and links to ensure on schedule delivery of order(s). Maintaining high standards of our extensive array of products, we focus on the quality of raw inputs and material used at the initial stages. With this, the final product comes out to be the finest.

ceramic pulley lagging

Get Price Quote

1 Piece (MOQ)

Pulley Lagging Works

3,000 Per Piece(s)

1 Piece(s) (MOQ)

We are also spl.in pulley lagging works by cold bonding cement with different types of rubber sheet according to our customers requirements.

Pulley Lagging Rubber Sheet

1,450 Per Square Meter

Rubber Pulley Lagging

4,500 Per Piece

100 Piece(s) (MOQ)

Pulley lagging increases the traction between the belt and the pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings and take-up. key benefits: Extends the life of key conveyor components. Reduces wear from abrasive materials. Prevents belt slippage by increasing the coefficient of friction between the conveyor belt and the pulley. Creates a self-cleaning action on the pulley surface and prevents the buildup of transported bulk material, water, snow or ice.

Pulley Lagging Rubber Sheet

Get Price Quote

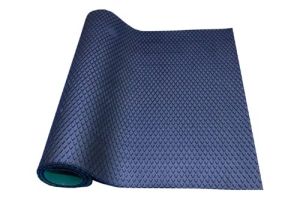

Pulley Lagging Rubber Sheet prevents belt slippage and protects from wear and corrosion and reduces material build-up. They also infuence belt tracking positively. They are available with plain, diamond or square profiles, with or without special bonding layer.They are manufactured from high-grade natural and synthetic rubber specially designed to deisplay excellent abrasion and ozone resistance. They are widely used in various industries for bulk handling and are resistant to adverse weather, temperature and radiation etc. It is vailable in a wide range of hardness from 40° to 70° Shore A and working temperature range of -30°C to +70°C.

Rubber Pulley Lagging

10,000 - 1,200,000 Per Piece

10 Piece(s) (MOQ)

Pulley Lagging Rubber Sheets

Get Price Quote

We are mfg. and distributors of positive drive pulley(Timing Pulley) . Timing Pulleys are manufactured from quality materials Ferrous and non-Ferrous and or as per customer's drawing. We exports rubber products like rubber sheets.Mainly we are involving with FORWEAR, FORCHEM, FORSKIRT, FORSYN.

Pulley Lagging Rubber Sheets

1,000 - 3,000 Per Meter

100 piece (MOQ)

Clients can avail a quality range of Pulley Lagging Rubber Sheets from us. These Pulley Lagging Rubber Sheets are known for improving the friction coefficient between conveyor belt and driven pulley, and thus are used for covering the pulleys under the rubber conveyor belt. These Pulley Lagging Rubber Sheets have diamond grooved design on top surface, and another surface is anti-skid that eases the installation. We use mixture of natural and synthetic rubber for the manufacturing of these Pulley Lagging Rubber Sheets. These sheets are used in various industries for bulk handling, and are resistant to adverse weather, temperature, and radiation etc. Features : Pulley Lagging Rubber Sheets are resistant to heat, oil, temperature, whether, ageing and are abrasion resistant for long term service. Application : Used in almost every industry for bulk handling. Size Length x Width : 1meter x 2 meters, or as per customer’s requirement. Thickness 8mm 10mm 12mm 15mm Surface : Smooth on both sides (plain rubber sheets) Diamond groove on one side & fabric-impression/smooth on other side. Skirt board rubber strips or sheets are also a part conveyor belt system; it is placed at both sides of conveyor belt to prevent the fall of material carried on conveyor belt. We manufacture skirt rubber sheets in a wide range of width, length & thickness.

Pulley Lagging Rubber Sheets

2,400 - 2,500 Per Piesq.m.ce

Pulley Lagging Rubber Sheet

1,800 Per Meter

100 Meter (MOQ)

Rubber Pulley Lagging

Get Price Quote

Smartist Industries offers a comprehensive range of Patterned Sheet Pulley Laggings to suit every conceivable conveyor installation. The Pulley Laggings offered by Smartist Industries are produced in different thicknesses, rubber qualities, and patterns to ensure the selection of the most appropriate type, to suit all application requirements. The Sheet Pulley Laggings offered by Smartist Industries come with CN Bonding Layers for better adhesion levels. The profiled patterns on the top surface, in diamond or square embossing, improve belt grip and tracking on conveyors, while reducing belt wear. The Sheet Pulley Lagging is available in various grades of rubber, including FRAS and oil-resistant grades.

Zenith Pulley Lagging Rubber Sheets

Get Price Quote

10 Kilogram (MOQ)

We offer zenith pulley lagging rubber sheets. Available with withwithout neoprene bonding in - small square large diamond designs

Diamond pulley lagging Rubber sheet

Get Price Quote

1 Piece (MOQ)

DIAMOND PULLEY LAGGING TROUGHED PULLEY CONVEYORS PULLEY LAGGING INTRODUCTION Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to pulley shells. Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the pulley. Notably drive pulleys are often rubber lagged for exactly this reason. This section provides some useful information regarding the different types of lagging as well as some technical details and recommendations for lagging of pulleys. DIAMOND PULLEY LEGGING Rubber lagging is applied to pulley shells in order to improve the friction between the pulley and the belt. Conveyor drive pulleys are often supplied with diamond grooved lagging as indicated in the adjacent sketch. ‘Diamond grooved lagging’ refers to the pattern in the lagging and this pattern, like with vehicle tyres, enhances the grip or friction even if the belt surface is dirty.

Diamond pulley lagging Rubber sheet

160 Per Kilogram

We are supplier of diamond pulley lagging rubber sheet. Its use in conveyor pulley .its very good quality of rubber.

Pulley Rubber Lagging

Get Price Quote

Pulley Lagging Rubber Sheet

550 Per Square Feet