Sponge Iron

SPONGE IRON also known as Direct Reduced Iron (DRI) is a substitute of steel melting scrap used mainly in electric arc and induction furnaces. We produce premium quality sponge iron already established and widely accepted in the market in medium scale. Presently we have capacity to produce 60000TPA to feed Induction and Arc furnaces. Major advantages for using Rexon Premium Grade Sponge Iron LOW PRODUCTION COST LOW POWER CONSUMPTION NO FURNACE EROSION & BOILING, HENCE MORE LINING LIFE LOW CONSUMPTION OF PIG IRON BETTER YIELD INCREASE IN PRODUCTION LOW BURNING GAS, HARMLESS TO WORKERS HEALTH MORE PROFIT

...more

M.S. Ingots

The Company has set up an induction furnace as a forward integration for production of steel ingots which has commenced production from Sept. 2004. It produces superior quality ingots to cater the needs of customers. The main advantages of using REXON Ingots are it is free from all harmful defects like Pipings, Cracks, Inclusions, Surface flaws etc.

...more

m s ingots

The main advantages of using Ingots are it is free from all harmful defects like Pipings, Cracks, Inclusions, Surface flaws etc.

...more

Iron Ore Pellets

Orissa is known as one of the largest mineral rich State in India having abundant mineral reserves of iron ore, coal, dolomite etc. required to feed steel plants all over India. After a long research and experiments by visiting different iron ore processing plants in China, the company has decided to establish one Iron Ore Pelletization project having a capacity of 300000 TPA as backward integration after in-house beneficiation of low grade iron ore fines with its own technology. Iron Ore Pellets are regarded as the superior feed material at lower cost as compared to calibrated iron ore. High quality pellets are being produced using iron ore fines duly beneficiated in-house for more value addition to raw-materials, which substitutes costly iron ore.

...more

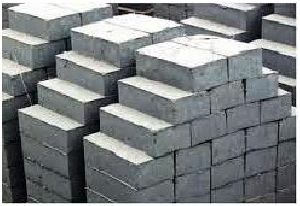

Fly Ash Bricks

The Ministry of Environment, Forest and Climate Change, Govt. of India, has made it mandatory for all builders to use only fly ash in building material if the construction falls within 500 kilometer radius of a coal or lignite based thermal power plant. We produce high quality Fly Ash Bricks which substitutes the burnt clay bricks. These bricks are most suitable for use in all masonry construction like common burnt red bricks. Advantages of using Fly Ash Bricks Environment friendly as it utilizes the flyash (byproduct) of coal based thermal power plants. Uniform shape / size which helps less usage of cement in brick and plastering work in comparison to red bricks. Fly ash bricks made building keep cool in summer because of low heat absorption. Absorbs very less water compared to red bricks. High comprehensive strength compared to red bricks.

...moreBe first to Rate

Rate ThisOpening Hours