Vibro Feeder

The Vibro feeders are used for discharging , per-screening and feeding of an even volume of non- sticking ,bulk materials form a hopper or a soil into the crusher , grinding plant or screening equipment , converging transportation etc. The per-screening of the material takes place on a installed screening grate with the size up to 150m.m. The feeder is driven by two attached vibrating motor. To change the feeding amount, adjust the unbalanced weights of the vibrating motor or change the frequency by the frequency converter. vibration feeder – many advantages : Resistance against clogging and sticking of the screened material on the screening grate The cascade design of the grate deck makes the screening of finer fraction more effective Minimum operation costs, which results form the balanced machine design, utilization of many years of vibration feeder operation experience and unification of parts. Easy exchange of the armoring High quality=High affectivity + High economic operation.

...more

Vibrating Screen

Impact crusher HSI : HIC impact crusher can be used for variety of jobs, including crushing of rock in quarries (limestone, dolomite, sandstone, gravel, etc,) and processing of building waste for recycling (concrete, brickwork, debris, bituminous materials at road reconstruction) HSI crushers many advantages: ► Advanced technical level which increases the affectivity of the operation ► High degree of comminuting, can be enhanced by incorporation an extra crushing route ► Variable construction of the box to incorporate the HIC crusher into stationary lines or mobile equipment ► Enclosed rotor body, fixed attachment of crushing bars in rotor Compact solution of flexible units, impact plates and crushing plate slot adjustment An easy access of operator during maintenance due to hydraulic opening of the crusher body ► High quality= highly range of HIC crusher application Variable design wide range of HSI crusher application : There is a wide range of application of HIC crushers due to variability of their design. The equipment can be adjusted to either stationary or mobile application by changing the location of the feeding hopper. The mobile adjustment complies with the requirements for the minimum height of the feeder and protection against shooting of the aggregate out off the internal space of crusher. The extra accessories, the crushing route, of the HIC crusher increase the crushing effect and the combination of the crusher material. The name of the crusher with the crushing plate includes mark The HIC crusher can be adjusted to crush materials with higher abrasion. The HIC crusher, which crushers abrasive material, includes A in its name.

...more

Vertical Shaft Impector

VSI impact crusher can be used for variety of jobs, including crushing of rock in quarries (limestone, dolomite, sandstone, gravel, etc,) and processing of building waste for recycling (concrete, brickwork, debris, bituminous materials at road reconstruction) Simplified Retro Fitment from Stone on Stone to Stone on metal : Stone on Stone To Stone on metal version can be easily converted by offering anvil Rings & Stone chamber combination which results in higher product yield. This simplified Retro fit can be easily & quickly installed on existing Stone on Stone model without changing the complete machine resulting in differing product needs. Features & Benefits The capacity data is based on computer models using stone with a bulk density of 1.6t/cubic meter. Actual throughput depends on a large number of factors and will vary between feed materials. Technical data and specifications are subject to change without notice.

...more

Single Toggle Jaw Crusher

In single toggle “LION” crusher crank shaft is accurately machined. Diameters are of considerable over size for normal loading thus it provide an important fatty factor against deflection. The crusher are specially fitted with anti friction roller bearing instead of brass on motor ending and will give greater production at lowest maintenance possible. In “lion” single toggle jaw crusher, will designed compression spring and spring-road provide to the toggle mechanism. Eliminate knocks and reduces the resultant wear. The easily replaceable toggle plate is designed for correctly jaws movement and act, as safeguard in the event unbreakable material accidently entering jaws. In “lion” single toggle, positive pressure grease lubrication protects bearing through specially designed labyrinth dust covers bearing and prevent excessive wear. Two heavy cast iron fly wheels are fitted plates made of manganese steel serve double faction of holding the fixed jaw in position and protecting the sides of the crushing chamber. It is very easily replaceable when wean wear becomes excessive. The body is made form best quality tested M.S. plate, welded fabricated construction. The end and side walls are stiffened with steel ribs of substantial proportion. The body is very strong and very light. In “LION” single toggle, heavy external ribs are wiled in place to reinforce of stiffen the frame points of maximum stress. Cast manganese steel jaw are highly wear resistant element of “”LION” crusher, the crushing surface of the jaw plates are suitably corrugated so that the riffles of the swing jaw exactly oppose the recesses of fixed jaw. The jaw plates are reversible when they wear at the throat.

...more

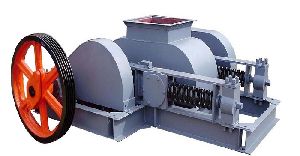

Roller Crusher

The roller crusher are used for fine crushing of wide variety of materials. The advantage of this kind of crushing is a significant reduction of occurrence of fine dust particles in the final product. ROLL CRUSHERS ► FORCES INVOLVED IN SIZE REDUCTION ARE IMPACT, COMPRESSION, ATTRITION AND SHEARING. LAWS INVOLVED IN SIZE REDUCTION ARE RITTENEGER’S LAW ,KICK’S LAW AND BOND’S LAW . SIZE REDUCTION INVOLVES REDUCING THE SIZE OF PARTICLES SO AS TO GET MORE PRODUCTS. SIZE REDUCTION ►The reduction ratio is the ratio of crusher feed size to product size. As stone passes through a crusher, the reduction in size may be expressed as reduction ratio. The degree of breakage is spread over several stages as a means of closely controlling product size and limiting waste material. The output of the primary crusher is fed to a secondary crusher, which further reduces the stone size. A primary crusher receives the stone directly from a quarry after blasting, and produces the first reduction in size. Crushers are classified according to the stage of crushing which they accomplish, such as: Primary, Secondary, Tertiary TYPES OF CRUSHERS ► Roll crushers have a theoretical Maximum reduction ratio particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch. Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm). A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rollsu Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing. ROLL Crusher Coal is probably the largest user of roll crushers currently though. Coal plants will use roll crushers either single roll or double roll as primary crushers, reducing the ROM coal. Rolls crushers are effectively used in minerals crushing where the ores are not too abrasive and they are also used in smaller scale production mining of more abrasive metal ores such as gold. Some major advantages of roll crushers are they give a very fine product size distribution and they produce very little dust or fines. The two rolls force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls. The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particle, called the nip angle. Working Principle and Structure of Double Roller Crusher :- ►This series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. ►The adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedge .The wedge-shaped device has a adjusting bolt on top, when the adjustment bolt pull up the wedge, the wedge will push the movable roller away from the fixed roller ,then the gap between two rollers is larger and produce larger particle size. When the wedge falls down, with the effect of the compression springs, the movable roller makes the gap become smaller between two rollers and thus produce the smaller particle size. Pad device can adjust the output size by changing the quantity of the pads or its thickness, Adding more pads, larger gap between two rollers, and when reducing the pads, it comes the smaller gap and smaller output size. DOUBLE ROLL CRUSHER ► Application of Double Roller Crusher The double roll crusher is applied in the industry of cement, chemical, electric power, metallurgy, building materials, refractoriness and other sectors for crushing medium hard materials such as medium and fine crushing of limestone, slag, coke, coal and other materials. It is more superior than ordinary crushers especially in the construction Materials Industry like isolate and green bean shake production. Drive device is composed of two electric motors. V-belt drags the rollers through drive of the grooved pulley move and rotate in the relative direction. In the crushing, the materials enter the feed opening and through the rollers, rolled and grinded, the finished products will discharge from under the chassis. For safety, drive part should install the security cover according to the actual situation respectively. ► SMOOTH ROLL CRUSHERS :- SUITABLE FOR FRIABLE AND BRITTLE MATERIALS LIKE COAL, SOFT LIMESTONE, SLAG,CLAY ETC THEY OPERATE BY COMPRESSION,IMPACT AND SHEAR AND SO IT CAN REDUCE MUCH LARGER PARTICLES THEY ARE MORE VERSATILE THAN SMOOTH ROLL CRUSHER BUT CANNOT HANDLE VERY HARD SOLIDS CONTAIN 1 OR 2 CURVED ROLL WORKING AGAINST A STATIONARY CURVED BEAKER PLATE TOOTHED ROLL CRUSHER · ► The extent to which the stone is fed uniformly into the crusher. The speed at which the rolls rotate The width of rolls The size of the finished product. The size of feed The kind of stone capacity of roll crusher. The capacity of a roll crusher will vary with: ► POWER CONSUMPTION OF ROLL CRUSHERS WITHIN THE SAME REDUCTION RATIO POWER CONSUMPTION OF ROLL CRUSHER VARY WIDELY THE POWER REQUIRED COULD BE GIVEN BY GENERAL EQUATION. ► ANGLE OF NIP ► IF CRUSHING ROLLS, 1M IN DIAMETER ARE SET SO THAT THE CRUSHING SURFACES ARE 12.5mm APART AND THE ANGLE OF NIP IS 31.WHAT IS THE MAXIMUM SIZE OF PARTICLES THAT SHOULD BE FED TO THE ROLLS PROBLEM QUESTION Crushers – many advantages: High technical level focusing on operation and maintenance Minimum dust particles in the product The rotor design makes the exchange of worn bandages easier Simple system of crushing slot adjustment and thus adjustment of outlet grain size Simple and unambiguous adjustment of the rotor thrust High quality =highly economic Construction solution >> easy operation and maintenance: The RCS crusher is easy to install. operate and maintain. The whole crusher including the rotor drives, is attached to the common frame. The rotor spring-mounting and slot adjustment unit has easily accessible and adjustable control elements. Service : Lion Jaw Crusher performs repair work and complete overhauls of jaw and cone crushers and screens including delivery of the spare parts. The inseparable part of service activities is a complete aggregate of pre- and after- sale services, as: ♦ Identification of customer's needs ♦ Cooperation during application draft ♦ Production of the equipment ♦ Putting into operation ♦ Training of operators ♦ Proving of project parameters ♦ Warranty and after-warranty repairs

...more

Oil Type Double toggle jaw crusher

This product is widely applied in middle and fine crushing of all kinds of ore, cement, refractory material, aluminum oxide grog, carborundum, glass raw material and other high hard and super hard material; as well as fine crushing of water, power, road, building, cement and metal mine industry. Double toggle jaw crusher : jaw crusher are preferably used at primary and second crushing of non-sickly medium hard and hard rock like granite, be salt, lime stone, etc. double toggle oil type jaw design has been focused to decreasing maintains cost and demands and to increasing their rascality and cutting operation costs sampling of an automatic grease lubrication a started. Oil type double toggle : The body is welded robust steel construction, very string and yet very light. Jaw crusher of “LION” crusher last longer as compared to jaw plates to the jaw plates of other crusher because “LION” jaw crusher work on the principle of “Crushing without rubbing” for different application suitable jaw plates are available and these can be fitted to the crusher without any difficulty. In “LION” jaw crusher automatic, continuous spray lubrication by positive gear pump for the pitman toggle mechanism enables the crusher to ruse safety. In “LION” jaw crusher massive rigid eccentric shaft of special steel is carried in sift aliened spherical roller bearings of ample capacity which ensures easily started with a normal duty squirrel cage motor. “LION” crusher have light-weight pitman having white metal lining for bearing surface which prevents excess friction. Double toggle, for even the smallest size crusher give even distribution of load. Well designed compression springs provide crushing to the toggle mechanism which Eli- mate knock and reduce the resultant wear. In “LION” crusher, strong hinge pin of special steel is located in connect relation to the crushing zone for crushing without rubbing. Its with specially designed oil resistant flexible diaphragm seals the opening in the oil chamber and protects the mechanism against dust.

...more

Mobile Crusher Plant

Mobile crushing plant, a new designed stone crushing & screening plant, which is flexible, convenient and strong in mobility, so it can save a large construction capital and relocation. Raw Materials can be broken at the locale without being transported again, and also can be moved with the promotional exploitation of the raw material, which saves a large number of transportation costs. lion engitech specializes in producing crusher, screen, transportation, and other stone breaking and minerals processing equipment. On the basis of the professional technology, we optimize and introduce newly two large and three small series crushing and screening equipment. The mobile series is tracked crushing plant, and the portable series is tyred crushing plant. Each large serie is divided into three series: rough, middle and fine crushing and screening mobile plant. Therefore, it can fully adapt to the various mobile crushing and screening, which creates more new business opportunities for customers while reducing the cost of the production. Features: Mobile Impact Crusher 1. A complete plant;All the machines are installed on the trailer, saves the occupation space, enhances the working efficiency. 2. Strong flexibilityIt can be moved from one place to another place. 3. High efficiency. 4. Works well and easy maintenance.

...more

Horizontal Shaft Impector

Impact crusher HSI : HIC impact crusher can be used for variety of jobs, including crushing of rock in quarries (limestone, dolomite, sandstone, gravel, etc,) and processing of building waste for recycling (concrete, brickwork, debris, bituminous materials at road reconstruction) HSI crushers many advantages: ► Advanced technical level which increases the affectivity of the operation ► High degree of comminuting, can be enhanced by incorporation an extra crushing route ► Variable construction of the box to incorporate the HIC crusher into stationary lines or mobile equipment ► Enclosed rotor body, fixed attachment of crushing bars in rotor Compact solution of flexible units, impact plates and crushing plate slot adjustment An easy access of operator during maintenance due to hydraulic opening of the crusher body ► High quality= highly range of HIC crusher application Variable design wide range of HSI crusher application : There is a wide range of application of HIC crushers due to variability of their design. The equipment can be adjusted to either stationary or mobile application by changing the location of the feeding hopper. The mobile adjustment complies with the requirements for the minimum height of the feeder and protection against shooting of the aggregate out off the internal space of crusher. The extra accessories, the crushing route, of the HIC crusher increase the crushing effect and the combination of the crusher material. The name of the crusher with the crushing plate includes mark The HIC crusher can be adjusted to crush materials with higher abrasion. The HIC crusher, which crushers abrasive material, includes A in its name.

...more

Conveyor System

We are Leading Manufacturer and supplier of Conveyor System for Crushing Plant.

...more

Cone Crusher

Hydraulic Cone Crusher is a new and efficient crusher researched and designed autonomously on the base of our Fifteen years' experience in the crushing industry engaged in design, production, sales and service, combining with the development of modern industrial technology, and drawing advanced crusher technology hydraulic cylinder cone crusher collects mechanical, hydraulic, electrical, automation, intelligent control technology into one set, and represents the world's most advanced crushing technology. It has a number of unmatched advantages compared to traditional crushers, high crushing efficiency, low production costs and easy to maintain and adjust, broken products with excellent grain type, and can be widely used in the medium crushing, fine crushing and super fine crushing operations. hydraulic cylinder cone crusher can be widely used in metal and nonmetal ores, cement, sand, metallurgy and other industries, suitable for the crushing various minerals and rocks whose Platt's hardness are less than 16, such as iron ore, nonferrous metal ore, granite, limestone , quartzite, sandstone, pebbles, etc. Technical data: 1. Large capacity and high efficiency; 2. Good cubical shape; 3. Easy to control and adjust accurately; 4. Stable operation and easy maintenance: (A). Hydraulic Cone Crusher adopts the structure of combining spindles floating and hydraulic lifting control system together, and takes discharge port adjustment and overload protect functions into one set , so that to ensure performance while simplifying the structure of the crusher. Compared to other types of cone crusher, it does not have to add complicated discharge opening adjusting device and overload protect system, so that its structure is more simple, and more reliable; (B). Uses positive pressure dustproof system to prevent dust from polluting oil, damaging bearings, thus to extend the life time of oil and equipment; (C). The hydraulic system is designed by high pressure to meet the needs of ordinary pressure, the equipment has higher margin pressure during normal operation, improving the reliability of the hydraulic system. The transmission system uses spiral bevel gear, which is reliable, stable, low noise, and long life. (E). All maintenances are operated from the upper part, facilitating inspection and maintenance; (F). Flexible to replace eccentric and adjust the eccentric distance, to meet different requirements of crushing; (G). Each type of cavity has a different size, which is easy to replace and suitable to different requirements for nesting; (H). Simple operation, to minimize the complexity of the work, and can control in long-distance.

...more

Crushing Machine

Be first to Rate

Rate ThisOpening Hours