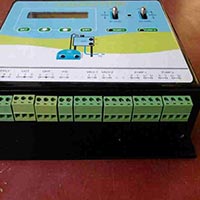

Pump Automation System

Get Price Quote

Features Automation System is advance micro controller based and designed for TWIN PUMP installations and can operate both pumps in wide variety of modes. The user can use the system on single pump installations also and the second pump control can be used as a redundant or stand-by feature. The operation of the pump is done by switch ON and switch OFF time, which is stored as one sequence in Automation System̢۪S memory. The user can set 9 sequences in a single day such sequence into Automation System. Automation System also gives Time Compensation against power bad condition. Automation System also equipped with LEVEL based pump control system. The system automatically starts the pump when water level down to set level in the OHT and stops the pump when water level reaches to high level in the OHT (Over Head Tank) or low level in the UGT (Under Ground Tank). The system does not allow starting the motor when water level in the UGT is not sufficient and protect the motor from dry run. Automation System provides protection against reverse phasing and single phasing. Automation System provides time delay (from 1 min. to 10 min.) when power recovers or pump tripped or pump OFF event occurs. This will be provided to avoid nuisance tripping, protects pump and prevents pipeline from back water thrust. Automation System also equipped with pressure sensing technology. In certain cases when all the taps of the pipelines are not in use (approx. 60% of taps are closed), pressure in the pipeline will rise and that damages the pipeline joints or pipeline. To protect from this over pressure, Automation System is equipped with settable pressure gauge. When pressure rise up to the limit, system will automatically tripped the pump and prevents the pipeline. For maintenance point of view, Automation System will continuously calculate and totalize total no. of hours of pump ON operation.