SELF PRIMING CENTRIFUGAL MUD/SEWAGE PUMP

SPM is a signle stage, Horizontal, Centrifugal, Self Priming, End suction Coupled pump.Automatic and quick self priming, no foot valve required. No priming of suction pipe line. Sturdy construction, and simple design. Minimum maitenance required. Non closing and handles soilds up to 17mm. Range Of Covergae Solids upto 17mm. Maximum Capacity : 77 lps. Maximum Head : 34 mtr. Material of Construction: CI, CS, SS, Alloy20 etc. Power Rating For Motor drive : 1.0 HP to 25.0 HP. For Engine drive : 6.0 HP to 26.0 HP Application Ideal for pumping sewage muddy water with solids upto 17mm. To handle polluted liquids, diesel, kerosene, effluents of chemical industries. Dewatering Foundations. Widly used for public and civil engineering.

...more

polypropylene chemical process pump

Polypropylene process pump is a horizontal single end suction standardized process pump. PP series process pumps are supplied with mechanical seal/gland packing arrangement covering 85% of chemical industries requirement. The pumps are manufactured from polypropylene copolymer-a chemically inert thermoplastic by the use of an exclusive moulding process. These pumps give you unusual protection against highly corrosive chemicals. The solid moulded casing and impeller ensure a smooth running pump for long life and a minimum of wear. All pumps, shafts are fitted with sleeves of different materials compatible with the liquid handled. Range Of Covergae Maximum Capacity : 70 m3/hr Maximum Head : 38 mtr. Maximum Temperature : 75O C Maximum Speed : 3000 rpm Material of Construction : Polypropylene Up to 2 HP Monoblock/Non-monoblock option available. Application Transferring of concentrated HCL Filter press for Dyes and Chemicals Effluent Treatment Water Treatement Plants. Scrubbing of Corrosive gases Like Ci2, Br2, F2, So2, So3, Co2, NH3, Descaling, Electroplating. Industries Where Used Dyes and Chemicals Drugs and Pharmaceuticals Causitic Soda Plants Thermal and Atomic Power Plants Fertilizer Plants, Copper, Zinc, Smelter Pickling in Steel Rolling Mills (Steel Pants) Paper & Pulp Industries

...more

HELICAL ROTOR PUMP

The unique pumping principle applied, employs a highly precision manufactured Metalic single helical rotor turning inside a double internal helical resilent stator. Thereby forming cavities confined by a "Sealing Line" which is maintained at stand still and during rotation. Whilst the rotor rotates in the stator, the cavity formed between them progresses from suction to delivery side, gently carrying the medium. Good self priming properties even with air or gas inclusion in the liquid upto 8.5 MWC. Handles solids in suspension or mixture containing high percentage of solids. Bigger size pumps upto 40mm dia. Steady and smooth flow with little pulsation makes it suitable for dosing and metering duties. Direction of the flow through the pump is reversible by merely changing direction of rotation of the prime mover. The pressure head is independent of speed and capacity is propotional to speed. Gate and check valves are not necessary. The metal bonded high precision moulded stator ensures high efficiency pressure and increases life.

...more

centrifugal chemical process pump

Constructional Features Top centerline discharge, self-venting casing arranged for back pull-out. Fully confined gasket. Foot support under casing for maximum resistance of misalignment and distortion from pipe loads . ANSI-B-16.5 (Class 150) flanges standard, ANSI-B16.5 (Class 300) optional for working pressure to 2550 kpa with 3mm corrosion allowance. For maximum corrosion , erosion resistance casting is supplied without tapped openings but gauge and drain plug openings are provided when specified. Impeller matched to casing for high efficiency and low NPSH. Fully open, has partial shrouds for maximum vane support without high thrust iherent in closed impellers. Stuffing box pressure reduced and entrance of solid prevented by back pump-out vanes. Large smoothly contoured flow passages combine best slurry and solid handling ability. Impeller is locked on shaft with impeller lock-nut and are sealed by PTFE gasket. State of the art casting methods smoothest possible surfaces for highest efficiency. All impellers are statically and dynamically balanced. Range Of Covergae Maximum Capacity : 80 m3/hr Maximum Head : 60 mtr. Maximum Working Pressure : 2550 kpa Maximum Temperature : 260O C Maximum Speed : 3000 rpm Material of Construction : CI, CS, SS, Alloy20, Hastelloy B & C etc. Application High Temperature liquids upto 260OC. Low specific gravitity hydrocarbons. Highly Viscous & high freezing point fluids. Corrosive acids Caustic Services Slurries Outdoor or Indoor Installation.

...more

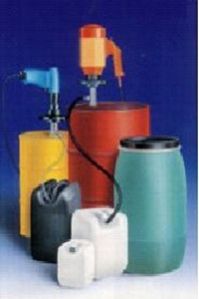

Barrel Pumps

Hacop barrel pumps are widely accepted barrel and container pump for handling highly viscos fluid & liquid upto 560 Cp. Pumps has been designed such that it can be used for various containers ranging from 25 Lts. Carboy to 500 Lts. barrels. Pumps are available in three different pump tube lengths i.e. L=700, 1000, 1250 mm. Application : Pharmacueticals, Cosmetics, Food, Breweries, Distilleries, Chemicals, Paints, Pesticides, Engineering, Textiles etc., DRIVE : ELECTRICAL OPERATED 560 Watts, 15000 rpm, Single Phase, Universal, Motor Operating on 220 Volts, 50 Cycles A.C. supply, Shock proof and Chemical Resistant Body. AIR OPERATED Operates on compressed air eathir at 4-6 bar pressure with an Air Consumption at 8-5 CFM and can be used for continuous operation. Use of FRL unit is recommended.

...more

Chemical Process Pumps

Mechanical Seal

engineering item

Be first to Rate

Rate ThisOpening Hours