AAC Blocks Making Machine

10,000,000 - 13,000,000 Per piece

1 Piece (MOQ)

Aac Block Plant

Get Price Quote

Best Deals from AAC Block Making Machine

Stationery Type Block Making Machine

Get Price Quote

1 Piece (MOQ)

AAC Autoclave Doors

350,000 - 650,000 Per Set

1 Set (MOQ)

Aac Block Cutting Machine

Get Price Quote

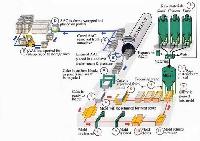

We are offering Aac Block Cutting Machine. AAC Block are made of flyash (limeslag or sand) as main raw material,cement and lime as cementing materials,and aluminum powder as foaming agent.The main forming procedures are Material crushing,measuring,mixing,pouring,curing,cutting and steaming.As a new wall body material with the characteristics of light weight, heat preservation,energy saving,waste recycling, environmental protection and convenience etc,AAC Light-weight block is now emphatically promoted by the world. First,Material Handling Jaw Crusher Mainly used for compressive strength less than 320 MPa materials, with big crushing ratio, high yield, even gra- nularity, simple structure, reliable operation, easy maintenance, low operating cost. The crusher has been widely used in mining, smelting, building material, highway, railway, water conservancy and other departments. Work principle of Jaw crusher: When jaw crusher works, the motor through the belts driven eccentric shaft rotation, so that the movable jaw cycle close, leaving the fixed jaw, multiple break materials through squeeze, rub, grind the materials, then make the material into small whereabouts, until discharged from the discharge door. Ball Grinder Ball grinder is used to grind a variety of ores and other mate- rials in the mineral processing, building materials and chemical industry. It can be divided into wet and dry two grinding types. According to the ways of discharging, it also can be divided into grid and overflow type. Beating Pool Pouring materials into pool and modulated into slurry. Silo Used for storing the Cement,Lime and other powder material, the effective volume are 100m³、200m³、300m³. Second, Dosing And Pouring Measure Measuring system is used to weigh each raw material. Pouring Mixer The casting mixer for mixing the slurry、powder、other materials and the aluminite suspended particles after being metered, then open the discharging valve, pouring the materials into the mould then send the products in the procuring room. Mould Slurry could be held in the combining of mould and side plate. After curing it would be solidified into the semi-finished pro- duct. Mould size:4.2m,6m. Side Plate The side plate is used to load the semi-finished product which will be cut by cutting machine and fed into the au- toclave to be hardened together with the trolley. Curing Room After pouring,use conveyor chain push mould into curing room under temperature 50-70 degrees. The curing time would be 1.5-2 hours.(according to favorable geographical condition, the step can be skipped.) Third,Tilting Cutter Turning Crane Lift the poured and cured product together with mould and side plate up in the air, turn it over 90 degrees to keep the block upright, carry it to the cutting cart, open mould and lift away the mould so that the semi-finished product can be out. Then mount and clamp the side plate on the mould once again, turn it over 90 degrees and carry it back to the starting line so that pouring can be resumed. Cutting Machine Operating principle: Using turning crane to turn the roughcast with 90 degree, left the roughcast with side plate on cutting cart after demoulding. Motor driven cutting cart move to length cutting device to process length cutting、groove milling、and horizontal cutting; Then the cutting cart move to the center of transverse cutting device, the transverse frame perform transverse cutting from up to down vertically. Afterwards the turning and grouping crane carry the roughcast(with side plank) to curing cart and the cutting cart return back to original position to have next movement. Turning & Grouping Crane After cutting, using the crane send the semi-finished products to the curing cart and grouping crane. Curing Cart Curing cart is used for carrying the product with side plate pass in and out of autoclave. The cut product is hanged with side plate to steam trolley and be carried into autoclave for curing. Fourth,Finished-Product Out From Autoclave Block Clamping Machine Carry the finished-product to packing line for making final package after autoclaved. Separator The separator is used to separate the plaster block into pieces, in order to be transferred and used. Autoclave Autoclave is a large pressure vessels used for steaming aerated concrete, sand-lime, fly ash brick or standard brick,the autoclave complete the hydrothermal reaction of CaO-SiO2-H2O. It is also widely used for other required pressure steam curing of the production project. Such as high-strength gypsum, insulation materials, rubber, high-strength glass, cement, pipe piles and timber, pharmaceutical, chemical and other industries. According to user requirements, our company can also design and manufacture of various forms of autoclave in order to meet the needs of the user a variety of purposes. Equipments. > BLENDER > SLURRY TANK > WIRE CUTTING MACHINE > STEAM CURING MACHINE > CONVEYOR BELT > SCREW CONVEYOR > AIR COMPRESSOR > ALUMINIUM POWDER MIXER > AUTOCLAVE > AUTOMATIC BACTHING CONTROL SYSTEM > AUTOMATIC CUTTING CONTROL SYSTEM > AUTOMATIC PLATE RETURING DEVICE > AUTOMATIC STEAMcart MOVING SYSTEM > AUTOMATIC VALVE CONTROL SYSTEM > BUCKET ELEVATOR > CRANE SUPPORT BEAM > MATERIAL HOPPER with VIBERATION MOTOR > MOULD > OUT-AUTOCLAVE DRIVING DEVICE with CHAIN > PACKING LINE > PULPING MIXER > SLURRY ELECTRONIC SCALE > SLURRY PUMP > THE STEAM-CURING CART > VERTICAL CUTTING MACHINE > WASTE RECYCLING MACHINE > WATER AND STEAM PIPES > WATER MESUREMENT SCALE More Details Call Our Toll Free No- 1800 200 11 71

AAC Blocks Making Machine

Get Price Quote

We are named among the renowned Suppliers of Blocks Making Machine. Made under the strict vigilance of experts, our AAC Blocks Making Machine is the perfect option for the buyers. It is well tested and therefore, is the perfect option on which buyers can easily rely. We have developed a vast distribution network, due to which, it has become easy for us to deliver retail as well as bulk orders for the machine on time. It can be obtained from us at the best market price.

Aac Block Machine

5,000,000 - 30,000,000 Per Set

Aac Block Cutting Machine

140,000 - 140,000 Per piece

1 pcs (MOQ)

AAC Block Manufacturing Plant

800,000 Per Unit

Aac Block Machine

Get Price Quote

We are a leading manufacturer and supplier of aac block plant we have been associated to block manufacturing technology since 1990 , from concrete block to flyash bricks , clc and aac , we have seen the change in the market, the product and all the advantages and disadvantages. In aac we have setup multiple turnkey projects, making our team has capable to execute aac block plant projects with ease. Since we have been innovating products for construction industry, our latest vision is to make this technology affordable to the masses. We are also designing smaller size plants which will help to reduce capital investment.

AAC Block Manufacturing Plant

60,000,000 - 500,000,000 Per set

1 Set(s) (MOQ)

Aac Block Making Machine

60 Per Piece

aac block making machines

Get Price Quote

Aac Block Machine

Get Price Quote

AAC Blocks contain 75% Air and therefore weigh only 13rd of a clay Brick. It is formed as a reaction of aluminum metal with blended proportion of lime, cement, gypsum & fly ash. The hydrogen gas escapes from the reaction giving AAC bricks a strong honey-comb structure. Also termed fly ash blocks these are further cured in an autoclave under high pressure steam to give it desired strength. The production process of AAC blocks has to be very carefully monitored to insure a controlled consistency in the proportions and timing of all ingredients that are used in each batch so that the output is consistent.

Autoclaved Aerated Concrete Block Machinery

Get Price Quote

1 Set(s) (MOQ)

Autoclaved aerated concrete plant we are specialized supplier of complete set of autoclaved aerated concrete plant with 50000, 100000, 150000, 200000, 250000, 300000, 350000m3 capacity annually (from 200 m3 to 1000 m3 per day), including plant design, equipments installation, technical instruction, personal training, etc., and also we design and manufacture as per clients' requirement. Autoclave aerated concrete production line included: raw material: cement, lime, sand, gypsum, aluminum powder, water. Equipment list: the equipment will be divided into two parts: specialized equipment and universal equipment. Specialized equipment includes: 1.cutting equipment: tilting crane, cutter. 2. Proportioning equipment: electronic measuring scale, slurry beating machine, slurry storage tank, slurry mixer. 3. Pouring and autoclave equipment: aluminum powder mixer. Pouring mixer, mould, side plate, autoclave truck, carrier car. 4. Conveying equipment: semi-product crane, end product crane. Universal equipment includes: 1. pressure vessel equipment: boiler, autoclave. 2. Crushing equipment: ball miller, crusher. 3. Transportation equipment: crane, lifting machine, feeder, belt conveyor, slurry pump, screw conveyor. 4. Enviornment protect equipment: dust remover

Aac Block Making Machine

Get Price Quote

The First advantage of Autoclaveed Aerated Concrete is designed for consumers who are environmental conscious it helps reduce at least 30% of environmental waste, decrease over 50% of greenhouse radiation and Over 60% integrated energy on the surface of brick. consumes Fly Ash, which is a big problem for thermal power Plants to dispose. it is environment friendly, because of no need of burning

Aac Block Machine

Get Price Quote

AAC block are used as much as like concrete blocks but AAC blocks are used mostly for wall Floor and roof decks of buildings. AAC & ALC blocks are largely used in various constructions, such as load bearing structure Building and wherever conventional bricks can be used. Using these blocks in structural buildings, the builder saves around 25 to 35% of structural steel and concrete. AAC blocks have a more accurate dimension and better comprehensive strength as compared to concrete block or Clay brick building. It has better strength because of thin bed mortar which provides better strength to AAC blocks. These green bricks can attain very regular & uniform shapes. As no burning is involved, so the shapes also remains unchanges.

Aac Block Machine

50,000,000 - 70,000,000 Per Set

1 Set (MOQ)

aac block machinery

Get Price Quote

Cellular concrete brick (light brick ) is a kind of light and porous buidling material., It's only weigh 500-700kg/m3, which is 1/5 of the ordinary blocks. It also has the nature of heat retaining and insulation, preventing fire and resisting earthquake. It can be make into many kinds of bricks (for example: 600× 200× 100mm, 600× 150× 100mm, 600× 300× 200mm, 600× 200× 150mm ). It is an ideal material used either in industry building and common building and has a bright future all over the world They will replace the Clay brick completely. Common concrete density is usually 1600-2400kg/m3, but light weight concrete are 500kg/m3, 600kg/m3, 700kg/m3. It has not the big grain, main use silicon material (for example: Coal ash, sand, stone dust and others ), through making the material small for example sand, they can be used directly if has enough degree of small (for example coal ash. Mixing calcium material lime cement water to a special slop, then add the aluminum dust and the additive. Make the aluminum dust and the special slop have a Chemical reflect. Then produce Hydrogen to make the concrete slop to expanding or swell, foam. Next, put them into the curing room to concreting cutting steaming curing. Last, there will bacome the light brick. The porous rate is 70-80%. Advantages of PNEUCON: - Large variety of sizes : PNEUCON can be produced in a large variety of sizes, from standard blocks to large reinforced panels. - Excellent thermal insulation : PNEUCON has a very low thermal conductivity and therefore a very high thermal energy efficiency is achieved. This results in savings on heating and cooling cost Bs. - Extreme lightweight : PNEUCON weighs approximately 50% less than other comparable building products. - High compressive strength : PNEUCON is a solid product, therefore making it highly load bearing. The entire surface area is used in structural calculations. - High dimensional accuracy : As a result of its dimensional accuracy, PNEUCON is extremely easy to install, as no thick set mortar is required. - Great acoustic insulation : The porous structure of PNEUCON provides a high acoustic insulation. Termite resistance : PNEUCON cannot be damaged by termites or insects. - High workability : As a result of the excellent size/weight ratio, constructing with PNEUCON is very rapid. Even though PNEUCON is a solid building material, it can be cut, sawn, drilled, nailed and milled like wood, making it an extremely workable product. Company Description: We specialize in manufacturing light weight brick or foam brick and various kinds of Brick Making Machine lines, By introducing the most advance technology in the world and long time improvement, we developed high quality block machine lines with practicable pattern and low cost. Now our products have been confirmed by more and more clients both domestic and worldwide and we have more and more new style models out our workshops. We hope to cooperate with more and more company worldwide by supplying our high quality products and service.

Aac Block Machine

Get Price Quote

AHP Machines is an Achieve Hydraulics group company specialized in producing various kinds of Fly Ash Brick machines, Paving Block Machines, CLC ( Cellular Light Weight Concrete) Machines, Cellular Light Weight Concrete Machines - CLC Machines, Autoclave Aerated Concrete ( AAC ), Laying Machines, Table Vibrators. We are Manufacturer, Exporter, Supplier & known for performance, innovative and economical production technologies and high reliability.

Aac Block Making Machine

Get Price Quote

We are the main supplier of this product.

Aac Block Making Machine

Get Price Quote

We are offering aac block making machine. Describe your product details describe your product details describe your product details

Aac Block Machine

Get Price Quote

We are offering aac block machine

Aac Block Making Machine

Get Price Quote

AAC Block Making Plant And Machinery is the basic equipment in any construction project.At Indian Trade Street users can find traders and manufacturer of AAC Block Making Plant And Machinery.

Aac Block Making Machine

Get Price Quote

Aac Block Making Machine, light weight concrete block, Sand Aac Block

Aac Block Making Machine

Get Price Quote

Aac Block Making Machine, Light Weight Concrete Block Machine

clc and aac block machinery

Get Price Quote

we are manufacturer and supplier of fully automatic clc and aac block machinery.including following machinery 1.mixer 2.foam generator 3.automatic wire cutting machine 4.moulds 5.feeding system

Aac Block Making Machine

Get Price Quote

Aac Block Making Machine

Aac Block Machines

60,000,000 Per Set

We are offering aac block machines.complete turnkey solutions to aac block projects with 100% indian machines.

Autoclaved Aerated Concrete Block Machine

Get Price Quote

Autoclaved Aerated Concrete Block Machine, Automatic clay brick making machine