Bamboo Strip Bending Machine

6,499 - 6,500 Per piece

1 piece (MOQ)

Key Features: Precise Bamboo Strip Bending: Our Bamboo Strip Bending Machine utilizes advanced technology to bend bamboo strips with accuracy and consistency. The machine applies controlled heat and pressure to the bamboo strips, allowing them to conform to the desired shape. This precision ensures that the bent bamboo strips maintain their form and structural integrity. Versatile Bending Capabilities: With our bending machine, you have the freedom to create various bending angles and curves. Whether you need gentle curves for furniture pieces or complex bends for architectural structures, our machine can accommodate a wide range of bending requirements. This versatility enables you to bring your creative ideas to life and explore different design possibilities. Adjustable Temperature and Pressure: The bending machine provides adjustable temperature and pressure settings, allowing you to customize the bending process based on the specific characteristics of the bamboo strips. This flexibility ensures optimal bending results while preventing damage to the bamboo material. You can achieve consistent and uniform bends throughout the bamboo strips. Efficient Production: Our machine optimizes the bending process, enhancing your production efficiency. It automates many of the manual tasks involved in bamboo strip bending, reducing labor costs and saving time. The precise and controlled bending ensures that the bamboo strips are ready for further assembly or incorporation into your products. User-Friendly Operation: While the machine harnesses advanced bending technology, it is designed for user-friendliness. The intuitive interface and controls make it accessible to operators with varying levels of technical expertise. Additionally, our team provides comprehensive training and ongoing support to ensure smooth operation and optimal results. Sturdy Construction: We prioritize durability and longevity in our machine design. The Bamboo Strip Bending Machine is built with high-quality materials, ensuring its stability and performance even under heavy usage. It is designed to withstand the demands of a busy production environment. Description Introducing the “Bamboo Strip Bending Machine” by Prashant Bamboo Machines – a specialized solution designed to bend bamboo strips with precision and ease. Our bending machine is specifically engineered to shape bamboo strips into curved or angled forms, allowing you to create unique and intricate bamboo structures and products. Why Choose Prashant Bamboo Machines? Industry Expertise: With years of experience in the bamboo processing industry, we possess in-depth knowledge of the specific requirements and challenges faced by manufacturers. Our machines are designed to meet these needs and deliver exceptional results. Quality Assurance: We are committed to providing machines of the highest quality. Each Bamboo Strip Bending Machine undergoes thorough quality checks and is built with precision to ensure reliable performance and longevity. Dedicated Customer Support: We value our customers and strive to provide excellent customer service. Our knowledgeable support team is readily available to assist you with any inquiries or concerns, ensuring a smooth and hassle-free experience. Competitive Pricing: We offer our Bamboo Strip Bending Machine at a competitive price, providing excellent value for your investment. Our goal is to help you optimize your production process without compromising on quality. Shape your bamboo strips with precision and creativity using the Prashant Bamboo Machines Bamboo Strip Bending Machine. Contact us today to discover how this specialized machine can elevate your bamboo processing capabilities and enable you to craft stunning bamboo structures and products.

5mm Wire Cutting & Straightening Machine

135,000 Per Piece

1 Piece (MOQ)

Best Deals from Wire Making Machines

IE-3F Cable Stripping Machine

32,500 Per Piece

1 Piece (MOQ)

Wire Drawing Machine

100,000 - 400,000 Per Sets

1 Nos. (MOQ)

Induction Based Annealing Machine

Get Price Quote

1 Piece (MOQ)

3 In 1 Compact Feeding Line

3,300,000 Per Piece

1 Piece (MOQ)

Multihead Wire Book Stitching Machine

170,000 - 215,000 Per piece

1 piece (MOQ)

Semi Automatic Egg Laying Block Making Machine (RBM-04)

Get Price Quote

Having accumulated knowledge and experience over the years, we are able to bring forth the supreme quality in the form of Semi Automatic Egg Laying Block Making Machine (RBM-04). We present incredible quality to our customers. We make use of top-quality raw material to ensure low maintenance, durability and elevated service life. It finds its application in several industries. Get in touch to avail highly competitive prices. Details : Egg-Lying Type Concrete Block Making Machine with Mould, Vibrator- 2HP-2800RPM OR 3HP Petrol/Diesel Engine, Block Capacity-1000/Shift. Model No. - RBM4

aluminium wire drawing machine

450,000 Per Piece

1 Piece (MOQ)

Automatic Wire Nail Making Machine

Get Price Quote

We are a well-known name as Automatic Wire Nail Making Machine Manufacturer, Exporter and Supplier in Punjab (India). The SMT Automatic high-speed Wire Nail Machines are made from high-grade castings and steel. Our Automatic Wire Nail Making Machines are simple and sturdy in design for friendly use. With advanced features, the Wire Nail Machines are known for their long lasting service. Automatic Wire Nail Making Machines can produce nails from H.B. brass, copper and aluminium wires. All the movements except the pressure for gripping and the ejection, are through cranks, which are essential for smooth running at high speeds maintaining full rate production of well finished nails. Special attention has been given to maintain easy approach to all the required adjustments and settings. Our Automatic Wire Nail Making Machines are available at very reasonable prices. Technical details : Inch 11 -2 -31 42 52 62 8 Gauge 20-1718-1416-1214-912-810-68-48-2 Type Unit SMT WN-1 SMT WN-1.5 SMT WN-2 SMT WN-3 SMT WN-4 SMT WN-5 SMT WN-6 SMT WN-8 Length of Nail mm 6.0-25.4 12.0-38.0 12.0-50.0 20.0-75.0 25.0-100.0 50.0-125.0 50.0-150.0 50.0-200.0 Wire Gauge mm 0.9-1.4 1.2-2.0 1.6-2.6 2.0-3.7 2.6-4.0 3.5-4.6 4.0-6.0 4.0-7.0 Output Pcs/Min 500-550 400-450 300-350 225-275 175-210 175-200 100-125 90-100 Power Required HP 1.0 1.05 2.0 3.0 5.0 5.0 7.0 10.0 Net Weight Kgs 225 350 500 850 1200 1500 2000 2500 Over all Dimensions(L*B*H) Inch 33*29*32 33*32*35 36*37*37 47*56*42 52*51*44 58*62*46 65*72*49 84*77*54 Note : *All specifications are subject to change without any prior notice.

cable crimping machine

Get Price Quote

Keeping the stern check on packaging procedures, we ensure that the products are packed using the finest packaging material, followed by a stringent check of the whole batch by the professionals. With the aid of our updated transit facilities, we are capable of delivering the orders at requested destinations with ease.

CB 328 Comb Binding Machine

5,500 Per piece

1 Piece (MOQ)

Film Stripping Device

Get Price Quote

1 Piece (MOQ)

Hydraulic Perfume Bottle Crimping Machine

22,500 Per Piece

1 Piece (MOQ)

hydraulic swaging machine

Get Price Quote

1 Piece (MOQ)

Copper Wire Stripping Machine

85,000 - 95,000 Per Unit

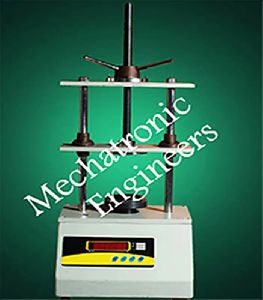

Spring Testing Machine

Get Price Quote

1 Piece (MOQ)

Features Microcontroller Based Advanced System Unit Force Measurement Accuracy ± 1% of Indicated Load Or 0.5% Of Full Load Value Whichever Is Higher Quick and Accurate Measurement Interchangeable Load Cells Simple Controls for Ease of Operation. Modulus Data for Load & Displacement (For Selectable Models with Software) Safe Operation Ensured by Means of Safety Devices. Simple Hand Operated Mechanism Optional Automatic Computerized Operation with Drive & Motor Available

Wire Nail Making Machine

245,000 Per Piece

Four Strand Wire Feeder Machine

Get Price Quote

Application : The machine serves to introduce Cored Wire into molten metal in ladle during the non-furnance treatment of steel (deoxidation, modification, desulphurizations, adding of alloying elements). This equipment was designed for the needs of large metallurgical plants. Operation Parameters : Diameter of Cored / Solid wires : From 9 mm to 16 mmVelocity of Wire Injection : Up to 300 m/min (400 m/min)Velocity Control : SteplessSetting Range of Meters : 0001 m ÷ 9999 m, every 1 mNumber of Feeding Strands : 4Number of Powered Rolls in One Strand : 4 Control : Control is performed with PLC. All parameters like wire length to be introduced into ladle and injection velocity are setting from keyboard of PC, independently for each strand. These parameters are displayed on PC monitor during the operation. After the START icon is clicked the appliance will introduce a required length of wire with predefined velocity into the ladle and will stop by itself when done. Then wire will be withdrawn automatically on the end of the feeding cycle.

Heavy Duty Aluminium Corner Crimping Machine

485,000 Per Piece

1 Piece (MOQ)