Autoclaved Aerated Concrete Block Machinery

Get Price Quote

1 Set(s) (MOQ)

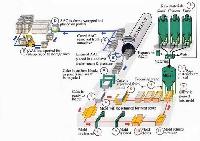

Autoclaved aerated concrete plant we are specialized supplier of complete set of autoclaved aerated concrete plant with 50000, 100000, 150000, 200000, 250000, 300000, 350000m3 capacity annually (from 200 m3 to 1000 m3 per day), including plant design, equipments installation, technical instruction, personal training, etc., and also we design and manufacture as per clients' requirement. Autoclave aerated concrete production line included: raw material: cement, lime, sand, gypsum, aluminum powder, water. Equipment list: the equipment will be divided into two parts: specialized equipment and universal equipment. Specialized equipment includes: 1.cutting equipment: tilting crane, cutter. 2. Proportioning equipment: electronic measuring scale, slurry beating machine, slurry storage tank, slurry mixer. 3. Pouring and autoclave equipment: aluminum powder mixer. Pouring mixer, mould, side plate, autoclave truck, carrier car. 4. Conveying equipment: semi-product crane, end product crane. Universal equipment includes: 1. pressure vessel equipment: boiler, autoclave. 2. Crushing equipment: ball miller, crusher. 3. Transportation equipment: crane, lifting machine, feeder, belt conveyor, slurry pump, screw conveyor. 4. Enviornment protect equipment: dust remover

Vibra Design Block Making Machine

Get Price Quote

In this process highly flowing concrete is poured into the rubber moulds and compacted in vibro-forming vibrating tables. The moulds with green concrete. If getting 24 Hrs overflat plate. The wet tiles are kept in a controlled atmosphere for 3 days for gaining more strength. Attractive long - lasting faces can be formed with the colour pigment added. Regular grey concrete with next ecomomically with two layers. Polyurethane or varnish coating can be applied for better attractiveness and wear resistance. We can use these rubber moulds for more than 300 times after washing. The high slump face concrete mix is to be mixed in a seperate exclusive tile mixer. The base grey concrete mix can be mixed with another tile mixer or a rugular drum type concrete mixer.The power consumption is 6 HP (3 HP x 2 Table). The Table weight is 650 kg Each.

Best Deals from Block Making Machine

Clc Brick Making Machines

Get Price Quote

Clc Brick Making Machines, Bentonite Earthing Powder, Construction Chemicals

Autoclaved Aerated Concrete Block Machine

Get Price Quote

Autoclaved Aerated Concrete Block Machine