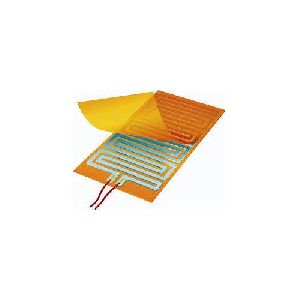

Polyimide Heater

100 Per Piece

200 Piece(s) (MOQ)

electric immersion heater

Get Price Quote

Raw Material Inputs: Copper Tubes Nicrome wire Insulation Powder (MgO) Brass Flanges, Screws and Nuts PROCESS Cut length copper tube Nicrome wire is wound like a coil on the coiler and terminal pins are spot welded on both ends The Coil is stretched inside the copper tube co-axial to the copper tube and cap is provided at one end and placed on to the filling machine and Insulation powder is filled through and the other end is closed with plastic cap and all pipes are removed in a batch. Squeezing Hot Annealing Bending Brass Flange Brazing Cleaning and Boring Nickle Plating Assembly Quality tests PACKING Each Heating element is wrapped in polythene cover and packed in a corrugated box and as per customer requirement

Best Deals from Electric Room Heaters