Silicone Coated Fiberglass Sleeve

5 Per Meter

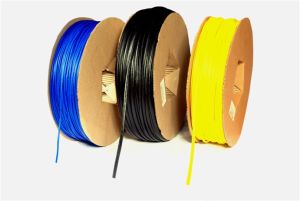

Silicon Sleeving

Get Price Quote

UL recognized GRADE “A” component under UL File No. # E324343 (UZFT2) and NEMA TF – 1 Type 5, Silicon Elastomer Coated Fiberglass Sleeving are flexible with an outer layer of Fiberglass braid. The over braid bonding process adheres the over braid to the silicon coated substrate and minimizes end fray to improve assembly performance and eliminate the long term handling effects of operator dermatitis. KIRAN KVPI – 200 sleeving is a high temperature Silicon Rubber Elastomer that is pressure bonded to a heat stabilized fiberglass braid. KIRAN VPI – 200 Silicon Sleeving is resistant to most acids, oils, organic solvents and water. It is also compatible with virtually all Electrical grade varnishes and Impregnation systems suitable for all VPI applications. This double wall sleeving provides higher abrasion resistance and for vacuum pressure impregnation. Overlap braid on sleeving being saturated has high resin absorption properties and are highly protective.

Best Deals from Fiberglass Sleeving

Acrylic Sleeving

Get Price Quote

Acrylic Coated Fiberglass Braided Sleeving are precisely engineered sleeving are flexible with an outer layer of E glass Fiberglass braid. The outer fiberglass braid is lightly treated with acrylic resin to prevent fray, improve abrasion resistance and allow coating by the VPI resin.Applications which require VPI processes and higher temperatures. It can be used for high voltage transformers as well as for aerospace and aircraft wiring leads. VPI-155 sleeving allows for expansion to fit over difficult joints and terminals KIRAN VPI – 155 with an over braided glass jacket. Lightly treated with acrylic resin to prevent end fray and improve abrasion resistance. Resistant to most acids and most organic solvents.

Fiberglass Sleeving Coated

Get Price Quote

We are offering fiberglass sleeving coated fiberglass sleeving coated with acrylic resin (kpg-701) it is a flexible class "f" insulating sleeving i.e. Fiberglass coated with acrylic resin. Used for fractional & integral horse power motors on leads & crossovers, dry end oil filled transformers. Fiberglass coated with acrylic resin provides excellent resistance to oil & benzene making it ideal for use in hazardous areas. It also possesses longer shelf life. Acrylic sleeving is recommended as a universal coated sleeving for all thermal requirements from class 30°c to class 155°c. product name : fiberglass sleeving coated with acrylic resin class type: "f" applicable specifications : astm d372 working temperature : from 30°c to 155°c, peak to 180°c for few hours characteristics: good mechanical resistance longer shelf life good compatibility with class "f" impregnation varnishes good behavior with soldering iron very flexible typical applications: acrylic sleeving is widely used in fractional and integral horsepower motors on leads and crossovers. also used in dry and oil-filled transformers, radio and television circuits, welding apparatus and many others. automobile harnessing. features: compatible with most magnet wire coatings such as polyester, acrylic, polyamide, epoxy and phenolic. inner diameter: 1mm to 40 mm. wall thickness: we offer customized thickness as per customer´s technical requirements. break down voltage range: from l kv to 3kv. color: natural, white & black, other colors available on special order subject to factory´s acceptance. length : continuous or one meter length. standards: bs-2848, 1973 is-11654 iec 60684-3

Fibre Glass Sleeves

Get Price Quote

Fibre Glass Sleeves, Cotton Tapes, FIBRE GLASS TAPES, insulating gum

Fibre Glass Sleeves

Get Price Quote

Fibre Glass Sleeves, Cork Sheet, insulating items, Rubber Products