hot dip galvanizing services

Get Price Quote

We are leading galvanizing company since 5 years. Our group is ISO certified 9001 :2015A unique combination of service and commitment to exceed your expectations through Hard Work, Innovation Technology, Customer Focus, Quality and Timely delivery are the Forte of Matrix Grating Pvt Ltd. We manufacture these products by strictly adhering to a number of internationally acclaimed standard and specifications. Our company has a highly sophisticated manufacturing unit equipped with advanced technologies. The unit isoperated by team of highly skilled techno crafts enriched with indepth knowledge in plating technologies & manufacturing process. As part of our ongoing commitment to excellence, we at Matrix Grating Pvt Ltd, follow a stringent quality control policy to ensure A-class quality in each and every product we manufacture at All the manufacturing process at our company are performed as per International norms and standards. We strictly adhere to a 7 tank process during galvanization of our products. Galvanizing is a central activity in the supply chain which offers scope for backward and forward integration. Fabrication for industrial and infrastructure projects. Trading of non-ferrous metal and scrap Open doors to Manufacturing/ trading of galvanized products such as cable trays, galvanized hardware, Transmission and electrical accessories, cold roll steel, structural steel like beams, TMT bars, Piping fo oil and sector Exposure to a various industries which require galvanizing and gain opportunities in expanding business. Application of Hot-Dip Galvanising Infrastructure Solar and wind energy Oil and Gas Railways Industrial Turnkey Project and many more……. Marine and Shipping Automobiles Telecommunication Electrical and Power Transmission

hot dip galvanizing services

Get Price Quote

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 840 °F (449 °C). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that protects the steel underneath from further corrosion in many circumstances. Why Us? We, Maheshwari Hot Dip Galvanizers, established in 1996 are engaged in Hot Dip galvanizing of Iron and Steel Structures. Our Plant is located 20 Kms from Nasik, towards Mumbai, outside Octroi limit on Nasik Mumbai Highway. Our Plot area is 11000 Sqmtrs and Plant area is 16,700 Sq. Fts.Our production capacity is 24000 TPA. We are operating Two Zinc Bath Kettles of sizes as under: Bath 1 : 5.0 mtr(L) x 0.8 mtr(W) x 1.2 mtr(D) Bath 2 : 8.6 mtr(L) x 0.8 mtr(W) x 1.2 mtr(D) Our plant is equipped with all the necessary infrastructure like E.O.T Cranes, Material Handling Systems, Finished Material Stock Yard, Weigh Bridge, ETP, Power backup, Testing & Inspection Laboratory, Tower wise Bundling and Packing, etc. Hot Dip Galvanizing is carried out as per latest international standards and specific customer requirements by our highly qualified and experienced team.

Looking for Galvanizing Services Providers

hot dip galvanizing services

Get Price Quote

Amit Sales Corporation Pvt Ltd offers exclusive Hot Dip Galvanizing services at reasonable prices in Ghaziabad. Our team of professionals provide magnificent services to the customers and also caters the need of the customers. Our services provide barriers and protection to the steel surface and are also durable to protect against corrosion. Hot-dip galvanizing helps in the reduction of maintenance of the equipment. Our services of hot-dip galvanizing not only provide protection but also provide brightness and also longer shelf life of the equipment. Our service provides complete protection against any type of imperfections. Our team of expert professionals takes care of severe quality checks of equipment after such services.

Hot Dip Galvanizing Service

Get Price Quote

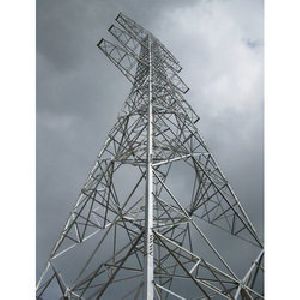

If you are looking for a trusted transmission tower fabrication service provider in Nashik (Maharashtra, India), then contact us. We have with us a dedicated team of professionals and highly advanced machines and tools using which we conduct the fabrication work of the transmission tower. We have with us experts who can easily conduct the welding service. Also, we can fabricate the towers as per the requirements of the clients.

hot dip galvanizing services

Get Price Quote

Fluxing The acid-cleaned steel article is immersed in a flux solution, usually 30% zinc ammonium chloride with wetting agents, maintained at about 65◦C. The flux solution removes the oxide film which forms on the highly reactive steel surface after acid cleaning and prevents further oxidation before galvanising. The work is then dried ready for galvanising. Galvanising On immersion in the galvanising bath the steel surface is wetted by the molten zinc and reacts to form zinc-iron alloy layers. To allow formation of the metallurgic bond the work remains in the bath until its temperature reaches that of the molten zinc, in the range 445◦C to 465◦C. The work is then withdrawn at a controlled The period of immersion in the galvanising bath varies from several minutes The resulting galvanised coating is tough and durable, comprising relatively pure zinc and zinc-iron alloy layers bonded metallurgically to the underlying steel, completely covering the article externally and internally, providing resistance to corrosion. The fact that hot dipped galvanising provides internal as well as external protection. Galvanising Facilities NSEPL Galvanizing 9 m long x 1.2m wide x 1.2m deep.NSEPL Galvanizing work 24 hours a day, offering industry leading turnarounds with the majority of work being galvanized within 2 days of receipt.The layout of the galvanizing facilities at Domjur, Howrah have been designed with customers in mind. The galvanizing facility is ‘in line’ allowing all our multi skilled employees to have access to any part of the production line. NSEPL Galvanizing have also set aside large areas for the checking in and out of the customer work aswell as a large, inside storage facility where quality is checked with diligence.NSEPL Galvanizing have been designed to cope with a wide variety of fabrications.Work galvanized by NSEPL Galvanizing comes from a wide spectrum of sectorsfrom Agricultural to Architectural. Advantages It worth considering the advantages of hot galvanizing in comparison with the most popular methods of metal treatment – painting and cold galvanizing. The advantagesof hot galvanizing are : Resistance to environmental impacts. Double corrosion protection High coating strength High wear resistance

Galvanizing coating job work

Get Price Quote

10 Pieces (MOQ)

hot dip galvanizing services

Get Price Quote

We are a leading service provider of Hot Dip Galvanizing Services in Delhi, India. This is a process of coating iron and steel with a layer of zinc by immersing the metal in a bath of molten zinc. They are carried on in controlled environment under the guidance of highly skilled professionals. We provide these services at leading market prices. Details : Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 840 °F (449 °C). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements. Galvanized steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel, and can be identified by the crystallization patterning on the surface (often called a "spangle").[1] Galvanized steel can be welded; however, one must exercise caution around the resulting toxic zinc fumes. Galvanized steel is suitable for high-temperature applications of up to 392 °F (200 °C). The use of galvanized steel at temperatures above this will result in peeling of the zinc at the inter metallic layer. Electrogalvanized sheet steel is often used in automotive manufacturing to enhance the corrosion performance of exterior body panels; this is, however, a completely different process which tends to achieve lower coating thicknesses of zinc.

Hot Dip Galvanizing Service

Get Price Quote

The facility is equipped with a highly efficient automated galvanizing system, which provides high-quality hot-dip galvanized products. A dichromate solution is applied to protect the galvanized coating during transport and storage. The zinc bath size is 10M long x 1M wide x 1.5M deep. Arious steel structures like Tower parts, Cable trays, Cross-barriers, , and Solar parts etc. Our Galvanizing plant process is taken place in fully automated temperature control galvanizing steel beams, channels and angles for other local customers. A new galvanizing plant will be installed shortly, which will be environment-friendly.

Hot Dip Galvanizing Service

Get Price Quote

With the continuous support and sincere efforts put by our experienced professionals, we have been able to provide our clients the best quality Hot Dip Galvanized Job Work. Offered service is performed under the strict supervision of our experts using optimum grade tools and latest technology. Our professionals perform this service as per the requirements of our clients. Further, the provided service can be availed by our valuable clients at most competitive price.

Galvanized Iron Ducting Services

Get Price Quote

Galvanized Iron Ducting Services

Sandblasting Services, Galvanizing Services

Get Price Quote

We are one of the leading service provider of sand blasting, zinc spray galvanizing services based at ahmedabad. experienced manpower with highly efficient machinery for better quality work.

Galvanizing Plant Fabrication Services

Get Price Quote

Ours is a trustworthy name instrumental in providing galvanizing plant fabrication services to our worthy clients across the nation. Operational from Maharashtra, India, we provide bespoke depending on the type of material, dimension, grade and industry usage. Clients can avail fabrication solutions for manual, semi-automatic or fully automatic plants. Furthermore, we have adopted modern work methods and fabrication techniques for efficient handling of the undertaken job. Visit us anytime for further discussion.

Galvanizing Services

Get Price Quote

Syndicate Industry is a preeminent name in the service sector of Delhi (India). We are in the business of providing best-in-class galvanizing services to the clients. We are backed by a team of ardent and meticulous professionals, who are proficient in executing various operations involved in the galvanization process. All you need to do is just connect with us by dialing our numbers at any time of the day.

Cold Galvanizing Coating Service

42 Per Square Feet

This coat is a Weather resistant, high performance Cold Galvanized coating system which may be applied in place of Hot Dip Galvanized process.Product Highlights Impermeability to Moisture Excellent Resistance to corrosion in the most aggressive conditions Excellent Resistance to UV Radiations Excellent Resistance to corrosive chemicals Benefits Excellent Replacement of Hot Dip Galvanization Process Off Site & On Site Application Easy Touch up & Recoating Easy application on existing galvanized surfaces Easy application with conventional tools Same or Superior finish than HDG Cost Saving upto 40% Recommended use A proprietary formulation specifically designed for use in aggressive environmental situations. To be used on steel alone to give long term corrosion protection. it offers excellent Aging & weathering resistance coupled with resistance to chemicals and is used to protect the metal components & structure in the most aggressive conditions.

Galvanised Mild Steel Fabrication

Get Price Quote

Dobriyal Brothers is a prominent name from Kotdwara (Uttarakhand) that offers premium galvanised mild steel fabrication to the clients. We use high grade galvanized mild steel materials to fabricate structures and products in sync of clients’ expectations. The galvanized MS structures fabricated by us demonstrate heightened structural stability, along with impressive dimensional accuracy. We use advanced equipment and tools to fabricate Galvanized MS structures as per the client’s specifications.

galvanization service

Get Price Quote

We are providing galvanization service.

Galvanizing Service

Get Price Quote

We are offering our clients with galvanizing services, wherein our skilled workers utilize the process of hot dip galvanizing for protecting steel from effects of corrosion. Herein, we coat the steel with a thin layer of zinc or iron alloy for enhancing its life. We deploy the ideal combination of zinc and steel for avoiding wastage of energy and raw material. Our galvanizing unit is equipped carry out our processes as per the specifications of BS, ASTM, JIS and DIN.

Galvanizing Service

Get Price Quote

We are engaged in offering Galvanizing Service to our esteemed clients across the country. We are backed by dexterous professionals who have great experience in this domain and in-depth practical knowledge of the Galvanizing process. We use high-grade zinc for galvanizing and make sure a proper coat is applied, to ensure client satisfaction. Owing to our reliable services and time bound delivery, we are regarded as a distinguished Galvanizing Service provider in J&K, India. What are Hot Dip Galvanising & its benefits?Hot Dip Galvanizing is a process by which steel is coated with molten zinc for lending it long- term resistance to any form of corrosion. First of all, the steel is chemically cleaned of impurities like oil, rust and surface mill scales. Once the cleaning process is done, the steel is then prepared for the coating process. A bath of molten zinc heated to around a temperature of 460°C is prepared and the zinc is then carefully immersed in the bath. After this stage, the steel is removed from the molten bath and shifted to a quench tank for cooling. Zinc coating is finally metallurgically bonded to the treated steel. Why Us? Competitive Market Prices Dependable Services Ethical Business Practices Client-centric Approaches Benefits of Hot Dip Galvanizing Excellent durability gives a permanently bonded tough coating Hygienic Surface can be easily cleaned Extended service life - No maintenance required for many years High corrosion resistance High abrasion resistance Economical Overall cost is very low when compared to other available coatings Excellent resistance to any kind of mechanical damage High impact resistance We do Hot dip Galvanizing for following items : Solar Panel Structures Cooling Tower Pipes Lighting Poles Steel Gratings Telecoms & Transmission Towers Road Crash Barriers Cable Trays Fencing Products & Clamps Shipping Material we are experts in zinc galvanization and silver plating we have an experience of 20 years in galvanizing. Excellent durability gives a permanently bonded tough coating Hygienic Surface can be easily cleaned Extended service life - No maintenance required for many years High corrosion resistance High abrasion resistance Economical Overall cost is very low when compared to other available coatings Excellent resistance to any kind of mechanical damage High impact resistance We do Hot dip Galvanizing for following items: Solar Panel Structures Cooling Tower Pipes Steel Gratings Earthing Strips & Plates Building structures like Angles, Channels, Purling, I-Beams, Gantry, Girders etc.

Galvanizing Services

Get Price Quote

J&SFI is an ISO certified firm and we can be reached anytime for acquiring services for zinc coated material. Our service center is located in Vapi (Gujarat, India) and we excel in galvanizing objects practically of any size. For ensuring high-quality solutions, we make use of the finest grade coatings and processing methods. A second level inspection is done by our quality inspectors before the material is shipped out from the premises. We work as per client’s schedule and other preferences; so contact us anytime.Five steps of galvanizing process are as under : Pickling - to remove rust or mill scaling, Rinse - to remove excess acid, Fluxing - for consistent and smooth coating, Galvanizing - to be dipped in molten zinc bath, excess zinc is drained out, Inspection - Cooled objects are inspected for any quality problems.

Hot Dip Galvanizing Service

16 - 28 Per Kg

3000 K (MOQ)

Hot Dip Galvanizing Service