printed hot stamping foils

30 Piece(s) (MOQ)

For the safe storage of our offerings, we have installed our own storage facility. Laced with modern amenities, our facility helps us in furnishing urgent requirements of the clients at a time. Buyers can place bulk as well as urgent orders with us and we make sure to deliver the same on time. Specifications : Comes in different lengths Material - Plastic Use - Usage - For laminating purposes Features : Smooth texture Light weight Fine finish

...more

Plain In Mould Label

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

Plain Hot Stamping Foils

40 - 65 Per Square Meter

2500 Square Meter (MOQ)

Noteworthy Supplier of Plain Hot Stamping Foils, we are customers' favored option in this domain. We have developed a large storage facility that is equipped with modern facilities for loading and unloading goods. Also, it assist us in meeting bulk requirements at a time. Specifications : Length: As per clients requirements Use : Usage - Packaging industry Features : Tear proof Optimum finish Light weight Additional Information : Minimum Order Quantity - 30 Roll

Country of Origin : India

Type : Hot Stamping Foils

Material : Pet

Thickness : 10-20micron

Application : Food, Pharma Industries

Color : Black, Blue, Green, Pink, Red, Silver, White, Yellow

Feature : Fine Finish, Heat Resistance, Moisture Proof, Shiny Look, Water Proof

Pattern : Plain

Width : 100-200mm, 200-300mm, 300-400mm, 400-500mm, 500-600mm, 600-700mm, 700-800mm

...more

Plain Hot Stamping Foil

46 Per Square Meter

5000 Square Meter (MOQ)

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of Heat, Time (Dwell) and Pressure to apply a Pre-Printed Graphic or image to a part. The Transfer Films offered by us are sourced from the Trustworthy Vendors of the Market. Application Heat Transfer Decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is an added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in Foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features: * Excellent definition with high speed made as per industry norms. * Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. * Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. * Good anti-scratch and rub resistance property. * All this with Rohs and En 71-3 passed. Advantages: Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us. Technical : We recommend product application.

...more

Plain Heat Transfer Label

46 Per Square Meter

5000 Square Meter (MOQ)

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of Heat, Time (Dwell) and Pressure to apply a Pre-Printed Graphic or image to a part. The Transfer Films offered by us are sourced from the Trustworthy Vendors of the Market. Application Heat Transfer Decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is an added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in Foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features: * Excellent definition with high speed made as per industry norms. * Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. * Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. * Good anti-scratch and rub resistance property. * All this with Rohs and En 71-3 passed. Advantages: Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us. Technical : We recommend product application.

...more

In Mould Label for Water Dispenser

5000 Piece(s) (MOQ)

Keeping in-line with the globally accepted standards, the raw material used for production is of high-grade. Thus, we always keep a check on the final product to make sure that the same is defect free. One of the major concerns of the organization is to make available only quality approved products to the buyers and thus we check the entire range at all stages. Use : Office House Home Features : Perfect finish Light weight Crack resistance

...more

In Mould Label for Plastic Table

5000 Piece(s) (MOQ)

We have a modern warehouse equipped to store a variety of products in bulk amount. Besides our wide distribution network, our warehouse enables us to maintain year round availability of products.We have a modern warehouse equipped to store a variety of products in bulk amount. Besides our wide distribution network, our warehouse enables us to maintain year round availability of products.We have a modern warehouse equipped to store a variety of products in bulk amount. Besides our wide distribution Catering to the voluminous and urgent requirements of our clients from Silvassa(India); count on us to avail the same Specifications : Available in several sizes Material Plastic Use - Usage - For the packaging of products Features : Smooth texture High strength Durable finish

...more

In Mould Label For Plastic Paint Bucket

500 Piece(s) (MOQ)

Buyers can consider our name for acquiring wide arrange of products that are quality-centralized and marginally priced. Our payment procedures are hassle free, safe, and legal. We do not impose hidden charges while creating the invoice and ensure your money is transferred securely from you to us. Specification : Size - As per clients need Use - Usage - Packaging industry Features : Sturdy design Light weight Leak proof

...more

In Mould Label for Pharmaceuticals

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

In Mould Label for Pesticides

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

In Mould Label for Pen & Marker

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

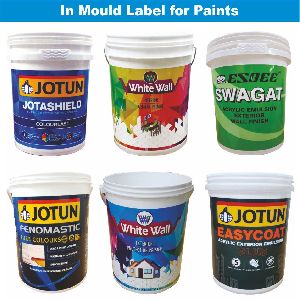

In Mould Label for Paints

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

In Mould Label for Lubricants

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

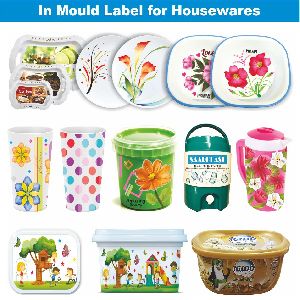

In Mould Label for House Wares

62 Per Square Meter

6000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

In Mould Label for Furniture

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

In Mould Label for Food Industry

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

In Mould Label for Fertilizer

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

In Mould Label for Cosmetics

62 Per Square Meter

5000 Square Meter (MOQ)

In Mould Label (Printed & Plain) What Is IML (In-mould Labelling)? IML is a significantly Growing Technology, which involves the label becoming an Integral Part of the Container, since the material of the Container & the Label is similar which help in Molecular Bonding.IML has been traditionally used for packing Yellow Fat, Ice-cream and Yogurt. It is now venturing into packing of other Prepared Food Products.In-mould Labelling combines Decoration and manufacturing of Bottle or a Container in one single process. Hence, IML is one of the Most Effective and Economical Product Decorating Processes, in the long run. Advantages: * A Polypropylene Container with a Polypropylene IML can be completely recycled in Most Domestic Municipalities. * The Containers have reduced exposure to Dort, Dust and other Contaminants. * Lower Cost than other Labeling & Printing Methods in the Long Run. * Higher Packaging Line Speed. Light weight of containers due to High Speed of Machines. * Improvement of sidewall strength of a container. Significant reduction in Product defected. * Best Performance of Labeling, because IML is a Part of a Container Wall. It cannot be peeled off as a PS or glue-on label can. * Better Appearance and Durability. Resistance to Product Staining. * Odd Shapes are possible. Square, Surround-wedges, Pyramids and other unusual containers can be Fully Decorated. Wagon wheel of the Advantages of In-mould Labelling: * 100% Hygienic * Spectacular Appearance * Better Self Life * Easily Recyclable * Completely Temper-proof * Labels are Non Peelable * Adhering to BIS & FDA * Allows for Bottom Decoration * Labels are Stain Resistant * No Secondary Operation required like in PS Labels

...more

hot stamping labels

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of heat, time (Dwell) and pressure to apply a pre-printed graphic or image to a part. The Transfer Films offered by us are sourced from the trustworthy vendors of the market. Application Heat Transfer decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is and added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features : - Excellent definition with high speed made as per industry norms. - Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. - Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. - Good anti-scratch and rub resistance property. - All this with Rohs and En 71-3 passed. Advantages of Heat Transfer Foils : Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us.

...more

Hot stamping Foils

46 Per Square Meter

2500 Square Meter (MOQ)

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of Heat, Time (Dwell) and Pressure to apply a Pre-Printed Graphic or image to a part. The Transfer Films offered by us are sourced from the Trustworthy Vendors of the Market. Application Heat Transfer Decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is an added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in Foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features: * Excellent definition with high speed made as per industry norms. * Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. * Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. * Good anti-scratch and rub resistance property. * All this with Rohs and En 71-3 passed. Advantages: Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us. Technical : We recommend product application.

Country of Origin : India

Type : Hot Stamping Foils

Material : Aluminium, Pet

Thickness : 10-20micron

Application : Food, Pharma Industries

Color : Black, Blue, Green, Pink, Red, Silver, White, Yellow

Feature : Fine Finish, Heat Resistance, High Strength, Moisture Proof, Shiny Look, Water Proof

Pattern : Plain

Width : 100-200mm, 200-300mm, 300-400mm, 400-500mm, 500-600mm, 600-700mm, 700-800mm

...more

Hot Stamping Foil for Pharmaceuticals

46 Per Square Meter

5000 Square Meter (MOQ)

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of Heat, Time (Dwell) and Pressure to apply a Pre-Printed Graphic or image to a part. The Transfer Films offered by us are sourced from the Trustworthy Vendors of the Market. Application Heat Transfer Decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is an added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in Foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features: * Excellent definition with high speed made as per industry norms. * Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. * Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. * Good anti-scratch and rub resistance property. * All this with Rohs and En 71-3 passed. Advantages: Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us. Technical : We recommend product application.

...more

Hot Stamping Foil for Pesticides

46 Per Square Meter

5000 Square Meter (MOQ)

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of Heat, Time (Dwell) and Pressure to apply a Pre-Printed Graphic or image to a part. The Transfer Films offered by us are sourced from the Trustworthy Vendors of the Market. Application Heat Transfer Decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is an added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in Foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features: * Excellent definition with high speed made as per industry norms. * Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. * Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. * Good anti-scratch and rub resistance property. * All this with Rohs and En 71-3 passed. Advantages: Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us. Technical : We recommend product application.

...more

Hot Stamping Foil for Pen & Markers

46 Per Square Meter

5000 Square Meter (MOQ)

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of Heat, Time (Dwell) and Pressure to apply a Pre-Printed Graphic or image to a part. The Transfer Films offered by us are sourced from the Trustworthy Vendors of the Market. Application Heat Transfer Decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is an added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in Foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features: * Excellent definition with high speed made as per industry norms. * Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. * Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. * Good anti-scratch and rub resistance property. * All this with Rohs and En 71-3 passed. Advantages: Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us. Technical : We recommend product application.

...more

Hot Stamping Foil for Paints

46 Per Square Meter

5000 Square Meter (MOQ)

We understand that the most important factor in Hot-Stamp decoration is durability and work ability. Our transfer films have the best transferring properties which you can ever have and allows the converters to make their own products decorative. This film is developed with very special coatings to give an excellent brightness after transferring on product. Heat Transfer Labeling is form of Product Decoration that uses various combination of Heat, Time (Dwell) and Pressure to apply a Pre-Printed Graphic or image to a part. The Transfer Films offered by us are sourced from the Trustworthy Vendors of the Market. Application Heat Transfer Decorating has become the preferred choice for customers looking for simplified, cost effective, high quality, consistent product decoration. The possibility for decorating seems endless at very low price is an added advantage of this product. All our offered range is manufactured keeping in mind the accurate demands of customers. We provide seamless look and suits mostly the round Containers, Barrels, Jars you can have Gold and Silver in Foil like effects. This can be printed in upto 10 colours. They are available for Barrels, Bottles, Containers made from PVC, ABS and PS, PC, PP, PET, Steel, HDPE etc. Features: * Excellent definition with high speed made as per industry norms. * Versatile in Plastic Components like PVC, ABS & PS, PC, PP, PET, Steel, HDPE having good coverage and adhesion with very high resolution print images and good coverage property. * Good heat & moisture resistance, weatherproof, waterproof, non fading, non peeling and tear resistance. * Good anti-scratch and rub resistance property. * All this with Rohs and En 71-3 passed. Advantages: Dry process : No Ink, Chemical etc. Multiple Colour : In Single Pass Application. Custom Color / Formulation : Specific for each application environmentally friendly. Unlimited possibilities : Only our imagination can limit us. Technical : We recommend product application.

...moreBe first to Rate

Rate ThisOpening Hours