Vibratory screener

The pellets & crumbs are usually screened to separate fines & over size particles before final packing. For removing fines only, we require single deck screener. For removing both the over size & fines, we need double deck screener. Our screeners are fitted with separate frames over which wire mesh is clamped and are designed for quick change of different mesh screens.

...more

SIMPLE FEEDER

Conventional vane type feeder has 6 or 8 vanes across the width of grinding chamber which has the drawback of feeding in slugs that causes uneven feeding

...more

Self Cleaning Designt

The magnets are of self cleaning design means you don’t have to remove the iron impurities from magnets by hand. It is now simplified with just unclamping the magnetic plate without using any tools and with just a pull of handle, all the entrapped metal falls in collection tray. Collection tray is detachable for cleaning.

...more

Horizontal Pellet Mill

Pelleting is a process in which mixed feed in powder form is converted into pellets by mechanical compression in combination with moisture and heat. Process is achieved by a set of rolls and die of suitable hole size and shape. As the die & roll rotate, the product passes through the nip of roll and die and pressed into die holes to make pellets.

...more

Horizontal Mixer

Vertical mixer has its shaft vertical which lifts the feed ingredients to the top and whirls it. Material then falls to the bottom cone and is again lifted. Process continues and a homogeneous mix is obtained. This mixer is suitable for mixing of dry ingredients only, as liquids are not mixed efficiently. We have made lot of modifications in this mixer for better mixing efficiency.

...more

full screen hammer mill

As its name implies, Full screen hammer mill have 80 % screening area as compare to 50 % in half screen hammer mill. This machine is an answer to many fine or coarse grinding problems that we usually face. Our Full screen hammer mill has so many other features also that make it an ultimate choice.

...more

Feeder For Hammer Mill

Even if a hammer mill is properly designed and well matched to its required job, it may not perform well if it is not fed properly. A typical hammer mill feeder is expected to meet following requirements. The feeder must provide a "UNIFORM CURTAIN" of materials to hammer mill grinding chamber. This curtain of material must be fed FULL WIDTH across the Grinding chamber of hammer mill.

...more

FEEDER

The function of Screw Feeder is to stop, supply & regulate the feed from Pellet bin to pellet mill through conditioner. Screw speed is varied by use of A.C. Electronic Variable Frequency Drive. All parts coming in contact with feed are of stainless steel construction.

...more

Elevator Head

Head is the top section of an elevator which consists of housing, top pulley, suitable drive mechanism, back stop etc. Our elevators are fitted with Top pulley which is driving pulley is rubberized to prevent slippage and crowned for self centering. Adjustable material Deflection plate with deflection tongues of obrasion-resistant rubber. Supplied with back-stop to prevent reversal of elevator on power failure causing jamming.

...more

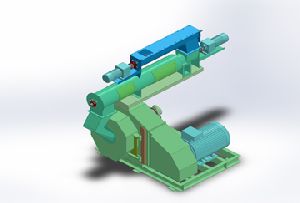

crumbler machine

Crumbling is the process of breaking pellets in small pieces by passing these through rolls rotating at different speeds having grooves on surface. After the hot pellets are cooled to the ambient teprature, the pellets may require breaking into small pieces to feed day-old chicks and grower flock.

Type : Automatic

Certification : CE Certified

Weight : 400-500kg

Voltage : 380V

Power : 1-3kw

Driven Type : Electric

Warranty : 1 Year

...more

Counter Flow Cooler

Hot pellets coming out from Pellet Mill are required to be cooled near ambient temperature to remove excess moisture and heat to improve the shelf life. Counter flow Coolers are fast replacing the old cross-flow or horizontal coolers as these are compact, maintenance free & highly efficient

...more

Hair Conditioner

Conditioning is a process in which heat, moisture & liquid is introduced to the feed. It consist of a single or double barrel in which one or two agitators revolve & perform the blending action. The retention time in Conditioner can be controlled either by varying the speed of the agitator or changing the angle of agitating blades. It has been generally recognized that proper conditioning will provide following changes: Product becomes more pliable for pelleting which results higher output with low power consumption, better pellet quality and enhanced Die life. Increase starch gelatinization. Increased feed temperature promotes the reduction of harmful bacteria such as salmonella.

...more

Cascading Magnet Devices

Different magnetic devices are used for separation of iron particles from material being processed. These include rotary magnets, magnetic grill, cascading magnets etc. Our cascading magnets are designed to catch iron impurities from very small particles of iron dust to big pieces with equal ease with almost 100% efficiency at maximum designed flow rate of plant. This is achieved by using high power rare earth magnets enclosed in stainless steel housing.

...more

Bucket Elevator

Bucket elevators are the most efficient means of vertically elevating most of the materials including grain, pellet and soft ingredients, finished feeds except sticky materials that will not discharge from the buckets. They consist of mainly three sections namely head, boot and casing.

...more

Auto Batching Proportioning System

For the production of quality feed, it is of utmost importance that all the ingredients and micro ingredients (vitamins, additives and trace elements) are measured in weight with high precision so that the desired percentage of each can be ensured in final feed.As the no. of ingredients and volume of production increases, it necessitates that the automatic weighing of all the ingredients is carried out. It generally consists of two set of proportioning bins with individual weighing hopper scale, one for major ingredients and second for micro ingredients. There may be any no. of bin from 2 to 20 for each set with suitable capacity and higher accuracy of weighing is required for micro ingredients. Auto weighing of liquids, fat, and oil can also be incorporated to the mixer.

...more

auto bagging

Our bagging machine is designed for automatic filling of material in open mouth bags. The machine is net filling type and in this, material to be bagged is weighed in a weigh hopper and is emptied into bag.

Machine Type : Net Filling

...moreBe first to Rate

Rate ThisOpening Hours