Waterjet Fabrics

It's an AALIDHRA product with several picks storage on drum, smooth storage forward on drum & enhancing easy unwinding, electronic FDP & weft pattern selection up to 32 different design & 65000 picks as stored simply by keyboard operation as displayed on screen

...more

water jet loom machine

Electronic let-off with forward & reverse inching synchronisation maintaining uniform warp tension up to beam exhaust. Highly precise mechanical take-up device keeps stable cloth fell assuring higher adaptability for wider range of fabrics. Most convenient and sturdy beam loading unloading and holding mechanism. Well engineered & sophisticate tension monitoring system control.

...more

Water Jet Loom

A new concept in weft feeding, meeting accurate length control, synchronisation with looms speed in close loop control, Highly reliable & maintenance free.

...more

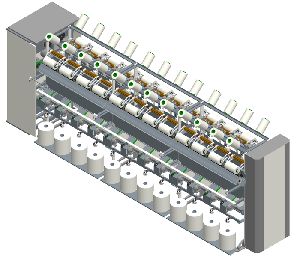

texturing machines

texturing machinesYarn Drive (all feed shaft) : With individual Steel roll for each end having low inertia with larger dia aluminum hub nip roll and self centering mounting for assured yarn feed. (second shaft with Apron yarn drive). CloseOpen Type Primary Heater : With three guide yarn entry assembly & optimized track contact pressure and track surface with well qualified heat insulation.

...more

Silk Yarn TFO

FEATURES S. S. Balloon protector. Detensioner pulley at Balloon guide to Reduce Balloon tension. Imported Nylon Sandwich Spindle Belt. Cork Sheet Drum to reduce Yarn Abrasion at Winding. Ceramic Teethed Gentle and Controlled Yarn Overfeeding at take up. Smooth and Controoled feed Package Unwinding By means of Flyer tensioner. Dual Traversing System for Paper Tube and Double Flange Bobbin as a takeup package.

...more

Silk Yarn Bobbin Winder

FEATURES Smooth and Gentle Unwinding of Stationary Pure Silk Hank as a feed Package. PLC Controlled Servo Traversing. Highly Sophisticate Take-up Bobbin Friction Driven Enabling Perfect Built. Positive Yarn Feed Results Uniform Density of Take-up Package. Excellent Yarn Path Design for Handling Delicate Pure Silk and Viscose Yarn. No Yarn Breakage at Power Failure.

...more

repair looms

Well Engineered Shedding Picking & Beating System Most Reliable Maintained next generations technology Highly Productive, Space Saver Operator Friendly Technology Sophisticated Sturdy Low Noise & Vibration Structure The heart of weft insertion is designed with AALIDHRA Concept incorporating global best components selection Electronic let-off with forward & reverse inching synchronisation maintaining uniform warp tension up to beam exhaust Highly precise mechanical take-up device keeps stable cloth fell assuring higher adaptability for wider range of fabrics Most convenient and sturdy beam loading unloading and holding mechanism Well engineered & sophisticate tension monitoring system control

...more

Precision Cheese Winder

Lycra Air Covering Machine

FEATURES Meant for Mfg. Variety of Value Added Air Covered Yarn for Stretch Fabrics Knitted Wear, Panty Hose, Socks, etc with Best Quality & Economy.

...more

Jari Covering Machine

jari covering machine We offer proven expertise in high-precision machinery for the extremely competitive Textile Industry. Being a pioneer in the Textile Machines Manufacturing domain, our company has risen to the status of a market leader by consolidating our position in the last three decades.

...more

Draw Winder

Aalidhra Draw assembly Winder is available with Single & Double side construction as well as Two & Three deck take-up. It is capable of producing Flat filament yarn having controlled shrinkage and warp workable yarn. With second feed (optional) installation it works as Draw assembly Winder producing Bi-shrinkage yarn and many more Bi-Componet value added yarns. Semi Rotary Creel provided with Two feed stands per position providing tail end facility. Yarn detector & Cutter provided to Avoid Yarn wrap on feed shaft at thread break in process. Draw and stability shaft provided with Apron Yarn nip & First and stability feed with nip rollers. Hot Pin provided in ASD-12/3D & Hot godet in ASD-12/2D as pre-heater. Intermingling jet provided between draw & stability shaft offers absolutely Controlled intermingling as required. Provision for second feed shaft together with necessary Extra detectors, cutters & yarn guides facilitate producing value added product as Draw assembly winder. 500 mm Close Contact type Vapour Phase group heater is absolutely capable of producing Low boiling water Shrinkage yarn (LBS yarns). Individual inverter driven motor drive system offers stepless parameter setting in running condition.

...more

draw texturing machine

Yarn Drive (all feed shaft) : With individual Steel roll for each end having low inertia with larger dia aluminum hub nip roll and self centering mounting for assured yarn feed. (second shaft with Apron yarn drive). CloseOpen Type Primary Heater : With three guide yarn entry assembly & optimized track contact pressure and track surface with well qualified heat insulation.

...more

Draw Texturing and Lycra Air Covering Machine

Double Density Draw Texturising Machine

cops winder

Frame Single Deck Both Side Traverse System Servo Motor With Ball Screw & Plc. Winding Type Warp, Random, Compound, Bottle, Bobbin, Combination Along With Coil Bind Technology. Spindle Type Heavy Duty Yarn Lubrication By Oil Roller Optional 1. Length Measuring Device With Microprocessor.

...more

cheese winder machine

Pre-Tensioner And Gate Type Tensioner Takes Care Of Unwinding Tension Jerks And Differences. Cradle Take-Up With Vibration Damping System. Adjustable Cradle Pressire Helps Hardness Control. Cyclic Trav. Speed Variation Avoids Pattern Formation. Cyclic Trav. Length Variation Avoids Hard Border. Sweep Type Knurled Yarn Oiler Rolls For Controlled And Uniform Oil Application. Maintenance Free High-Tech Traverse Box Helps Best Package Built.

...more

air covering yarn machine

Meant for Mfg. Variety of Value Added Air Covered Yarn for Stretch Fabrics Knitted Wear, Panty Hose, Socks, etc with Best Quality & Economy.

...more

Textile Machines

Threads

Garment Machinery

Be first to Rate

Rate ThisOpening Hours