Solvent Free Anti Corrosive Paint

3,900 Per Litre

20 Litre (MOQ)

Solvent-free anti-corrosive paint is environmentally friendly, provides corrosion protection without solvents, and can be applied to various surfaces using conventional techniques. It dries relatively quickly, offers excellent durability against UV rays, chemicals, and abrasion, and is commonly used in industrial settings. Follow product instructions and consult experts for proper usage.

Corrosion Inhibitors

Get Price Quote

Best Deals from Anti Corrosion Products

Industrial Deaerator

Get Price Quote

We are a popular Manufacturer, Exporter and Supplier of Industrial Deaerators from Gujarat. Industrial Deaerators are widely used in power plants and industrial installation. Industrial Deaerators are used to remove dissolved oxygen from boiler water. Our Deaerators work so well that after processing the outlet water has less than 0.05 PPM dissolved oxygen. Features : High Durability Easy to clean Customized as per our precious customers specifications

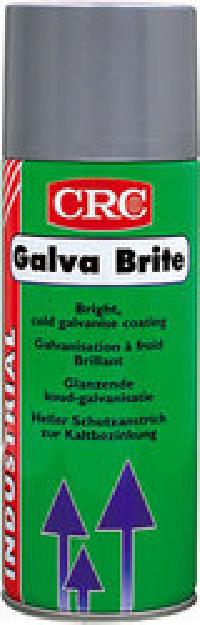

CRC Galva Brite Cold Galvanizing Spray

Get Price Quote

We offer crc galva brite cold galvanizing spray. 1. General description protective zinc-aluminum coating. a single component, zinc-aluminium coating combining corrosion protection properties with the lustre look of aluminium. Galva brite is a combination of zinc and aluminium powders, resins and additives, formulated to form a flexible protective film with a bright, glossy appearance. 2. Features excellent touch-up for galvanised surfaces. Provides excellent corrosion and rust resistance to ferrous metals. The galvanic properties ensure cathodic protection (the coating becomes the anode). Unique combination of flexibility and hardness. Resists rusting, peeling and fading. Adheres well to metal surfaces. Combines the galvanised look with the convenience of an aerosol application. Totally lead and chromate free. No chlorinated and low-aromatic solvents. Aerosols use dimethylether (dme) propellant for controlled spray and film properties. 3. Applications fences and gates home, garden and farm equipment construction equipment structural steel guard rails welding seams pipes and fittings coastal and ship-borne installations repair of lpg storage tanks

Corrosion Inhibitors

Get Price Quote

Corrosion inhibitor. A corrosion inhibitor is a chemical compound that, when added to a liquid or gas, decreases the corrosion rate of a material, typically a metal or an alloy. The effectiveness of a corrosion inhibitor depends on fluid composition, quantity of water, and flow regime.

Corrosion Inhibitors

Get Price Quote

2-acetylthiophene, Losartan Potassium, Olmesartan Medoxomil

Anti Corrosive Chemicals

Get Price Quote

We are offering anti corrosive chemicals. ecosoul is an organophosphonate and a polymer based chemical; ideal for removing and preventing scaling from any kind of a cooling tower & piping network. Ecosoul has the capability to do the task of an anticorrosive and antiscaling chemical simultaneously. Hence there is no need to put two different chemicals together.benefits of using ecosoul:anticorrosive benefits of ecosoul1) it increases the life of the cooling tower & it’s pipelines.2) reduces the maintenance costs.3) reduces the operating costs.anti scaling benefits of ecosoul1) reduces the maintenance cost.2) maintains the same water flow rate in the circulating pipelines in any system e.g. Cooling tower and chilling plant.3) maintain the efficiency of the pump.other benefits of ecosoul1) it is a highly concentrated chemical, hence a small quantity can give the desired results.2) it is efficient even when the ph of the water is 8.5.3) handling is very simple; ecosoul replaces two chemicals from the system like cooling tower.4) just by using this single chemical to cooling tower it replaces three cooling tower chemicals like (a). H2so4 acid, (b). H3po4 , (c). Nalco chemical etc.

Corrosion Inhibitor

Get Price Quote

Corrosion inhibitor exclusively for pipe lines for hydro testing where water used as a fluid. Nitrite based liquid used as a corrosion inhibitor in closed circulating coolingchilling water system. High performance corrosion inhibitor in closed re-circulating chilledwater system. It is a combination anodic nitrite base corrosion inhibitor along with azole to take care of multi metal base chillingclosed re-circulating cooling water system.

Corrosion Inhibitors

Get Price Quote

Powerful acid inhibitor for Cu metal. Powerful acid inhibitor for hydrochloric acid. Advance formulated copper metallurgy corrosion inhibitor (Concentrated). Corrosion inhibitor exclusively for pipe lines for hydro testing where water used as a fluid. Nitrite based liquid used as a corrosion inhibitor in closed circulating coolingchilling water system. High performance corrosion inhibitor in closed re-circulating chilledwater system. It is a combination anodic nitrite base corrosion inhibitor along with azole to take care of multi metal base chillingclosed re-circulating cooling water system.

laser cleaning machine

Get Price Quote

Corrosion Inhibitor

Get Price Quote

Metals are widely used in the construction of equipment associated with aqueous systems in which metals remain in contact with aqueous fluids on a regular basis, for example, hydro-testing of metallic equipments, fire extinguishing systems containing water, cooling or heating systems, heat exchangers and many more. The aqueous system generally contains vessels, piping, valves, etc. When water comes in contact with these systems, corrosion of the metal, during and after contact, is a concern. Corrosion Inhibitor SAC-CI 100 when added to water in small concentrations is able to prevent corrosion during wet storage. The corrosion inhibitor prevents corrosion even after vacating water from the system. Our Corrosion Inhibitor SAC-CI 100 is a combination of corrosion inhibitors, alkalinity builders, passivator, surface modifiers, chelating agents, oxygen scavenger and capable to protect various metals from corrosion even in the presence of relatively high concentrations of Chloride and Sulfate ions. The Corrosion Inhibitor SAC-CI 100 is suitable to reach every corner of the part / system that requires protection from severe corrosive atmosphere. Mechanism : The mechanism of Corrosion Inhibitor SAC-CI 100 is to prevent corrosion of metals in three phases: within the solution, at the water line, and above the water line. Our Corrosion Inhibitor SAC-CI 100 also prevents corrosion in the areas which are not reachable with other corrosion inhibitors. Features And Benefits Of Using SAC-CI 100 : No heavy metalsProvides up to 24 months of continuous protectionProvides mono-molecular inhibiting layer (protection layer) Additional Benefits : The product provides vapor-phase inhibiting action which protects inaccessible and recessed surfacesNo regeneration required; effective for up to 24 monthsIf the protective layer is disturbed by moisture or opening of the enclosed space, the layer is replenished by continuous vapour protectionLittle or no surface preparation required and easy to applyPrevents further corrosion of the pre-coated and painted surfacesThe protection layer does not need to be removed prior to processing or useThe protection layer does not interfere with operation of mechanical components Application And Additional Applications : Typical aqueous systems include, but are not limited to : Open re-circulating cooling systems, closed loop cooling systems, boilers and similar steam generating systems, fire fighting systems where water remains in constant contact with water, heat exchange equipment, reverse osmosis equipment, oil production systems, flash evaporators, desalinization plants, gas scrubbers, blast furnaces, paper and pulp processing equipment, steam power plants, geothermal systems, food and beverage processing equipment, sugar evaporators, mining circuits, bottle washing equipment, soil irrigation systems, closed circuit heating systems for residential and commercial use, aqueous-based refrigeration systems, down-well systems, aqueous machining fluids (e.g. for use in boring, milling, reaming, broaching, drawing, turning, cutting, sewing, grinding and in thread-cutting operations, or in non-cutting shaping, spinning, drawing, or rolling operations), aqueous scouring systems, aqueous glycol anti-freeze systems, water/glycol hydraulic fluids, ferrous-surface pre-treatment, polymer coating systems, and the like. Various types of water may be utilized in such systems, for example fresh water, brackish water, sea water, brines, sewage effluents, industrial waste waters. Additionally The Product Is Very Suitable For The Following : Hydro-testingLong term storage of waterTubular structures, pipes and vesselsInternal surfaces of compressors, turbines, engines, tanks, boilers, heat exchangersClosed circuit cooling systemsEquipment protection after hydrostatic testing Metals Protected : Carbon steelMild steelStainless steelCopperBrassAluminium Direction For Use : The product dose depends on quality of water and corrosive tendency of atmosphere also in some cases. But in general 10 to CI 1000 PPM is sufficient. More particularly, the dose may be 300-500 PPM. The product may be dosed by a slug feed or by blending with the aqueous fluid as the system is being filled. One can dose the material continuously using metering pump also. The pH of the aqueous system in which the product may be applied ranges from about 5 to about 12. The pH is preferably in the range from about 6 to about 10. The dosage can be increased for more severe conditions. Storage : Store in a sealed container in a dry warehouse, avoiding direct exposure to sunlight, with temperatures not exceeding 150oF (66oC). Under these conditions, shelf life is up to 24 months. Packing : The product is available in 50 to 200kg HDPE carboys. Safety precautions : Before handling the product, refer material safety data sheet which contains detailed information about this product (available on request).

Deaerator

Get Price Quote

We offer deaerator.

Corrosion Inhibitor

Get Price Quote

Corrosion Inhibitor, Water Treatment Chemicals, ANTISCALANT, microbiocide