biofuel plant

2,500,000 - 15,000,000 Per Piece

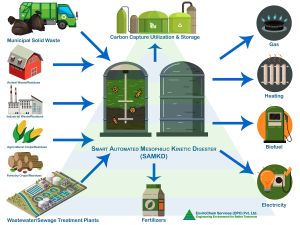

EnviroChem Services (OPC) Pvt. Ltd. is pleased to introduce our Bioethanol Plant, a sustainable solution for producing bioethanol from renewable biomass feedstocks. Designed with cutting-edge technology and engineering expertise, our Bioethanol Plant offers a cost-effective and environmentally friendly alternative to traditional fossil fuels, contributing to the reduction of greenhouse gas emissions and dependence on finite resources. Key Features: Feedstock Flexibility: Our Bioethanol Plant is capable of processing a wide range of renewable biomass feedstocks, including corn, sugarcane, wheat, barley, switchgrass, and agricultural residues. This feedstock flexibility allows for optimal resource utilization and adaptation to regional agricultural conditions. Advanced Pretreatment: We employ advanced pretreatment technologies to prepare biomass feedstocks for ethanol production. This may include mechanical size reduction, enzymatic hydrolysis, chemical pretreatment, and thermal processing to break down complex carbohydrates and enhance fermentability. Fermentation Process: Our Bioethanol Plant utilizes microbial fermentation processes to convert sugars derived from biomass into ethanol. We employ robust fermentation strains and optimized fermentation conditions to maximize ethanol yields and production efficiency while minimizing energy consumption and process time. Distillation and Purification: Following fermentation, ethanol is separated and purified through distillation and rectification processes to obtain high-purity ethanol suitable for fuel or industrial applications. Our distillation systems are designed for energy efficiency and minimal environmental impact, utilizing advanced separation techniques and process optimization strategies. Co-Product Recovery: In addition to ethanol, our Bioethanol Plant produces valuable co-products such as dried distillers' grains with solubles (DDGS), a high-protein animal feed supplement. We employ integrated co-product recovery systems to maximize the value and sustainability of the ethanol production process. Energy Integration: Our Bioethanol Plant incorporates energy integration and optimization strategies to minimize energy consumption and maximize energy recovery. This may include heat exchange systems, cogeneration of electricity and heat, and utilization of renewable energy sources such as biomass or biogas. Environmental Compliance: We adhere to stringent environmental standards and regulatory requirements throughout the design, construction, and operation of our Bioethanol Plant. Our plant design minimizes emissions, waste generation, and environmental impact, ensuring compliance with local, national, and international regulations. Applications: Biofuel Production: Our Bioethanol Plant produces ethanol for use as a renewable transportation fuel, blending with gasoline to reduce greenhouse gas emissions and dependence on fossil fuels. Industrial Applications: Ethanol produced by our plant can be used as a solvent, intermediate chemical, or raw material in various industrial processes, including chemical synthesis, pharmaceuticals, cosmetics, and personal care products. Renewable Energy Integration: Ethanol produced from renewable biomass sources contributes to the diversification of energy sources and the transition to a low-carbon economy, supporting sustainable development and energy security initiatives.