Universal Loop Steamer

Get Price Quote

We provide a vast range of Loop Steamer/Curing / Polymerizing Machine in India. The fixation of dyes on fabric is made by a polymerization in hot air at 150°C. We have improved the polymerization process on fabric moves in tension-less condition by our quality Curing / Polymerizing Machine; there is no rubbing and no lengthwise stretching on printed fabric. For low temperature steaming the textile processing machine has a chamber roof which is heated by steam coils preventing condensation and drippings. Our steam agers are equipped with special device, a Steam Saturator, which conditions the steam passes through the water before being injected into the steaming chamber. These particular characteristics of steam pre- conditioning which prevent and control the exothermic reaction of the fabrics and of the printing paste, make our machine " UNIQUE" of its kind and are the basis of great success achieved all over in textile industries. For high temperature steaming our steam agers are equipped with efficient re-circulation system and heat exchangers using Thermic Fluid which ensures uniform temperature in the chamber. Special system to allow air to re-circulate instead of steam permitting polymerization treatment with hot air upto 160°C. Some of the important features are:- The machine is essentially built on a steel frame with insulation panels containing mineral wool. Inside the machine, centrifugal blowers are mounted that suck surrounding air through a filter and blow into the machine chamber. This blowing is done from the bottom, underneath the heaters. In this way, the fresh air is first heated and then mixed with the circulation air. Eventually oil condenses or hydrocarbons, which develop during fixation, are removed through an exhaust fan partially and partially re-circulated air-to-air heat recovery within the chamber. The fabric transports on free loops, quantity of fabric contain from 50 meters to 250 meters and working fabric width available from 1200mm to 3300mm. Some special de-ionization bars are installed at the inlet and outlet to reduce the fabric electrification phenomena. The air heat is reached by thermic oil battery or direct gas burner. The machine is usually equipped with electric control panel and on request it is possible to supply a logic programmer.

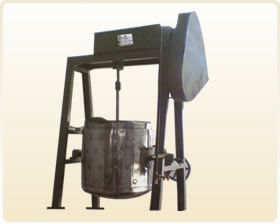

cooking pan

Get Price Quote

1. Version : Tilting & Stationary 2. Heating : Steam & Thermic Fluid. 3. Faster & even cooking of gum which results in the time & energy saving. 4. Truck Crown & pining for longer life. 5. Stiffners to avoid bulging.

Best Deals from Cookware

Stainless Steel Kadhai

3,444 Per Piece

250 Piece (MOQ)

Loop Steamer for Digital Printing

5,000,000 - 10,000,000 Per Nos

Some important features of the RECKON make Loop Ager Machine: 1. Compact steaming chamber design to reduce steam consumption. 2. Even distribution of steam in chamber, steam being injected from the top and being lighter than the air will force to remove air and exhaust from bottom will be occupied in the process chamber fully and thus leaving no chance of air inside the steaming chamber. 3. Optimum steam conditioning and humidification with parallel flow inside the steamer. 4. Conveyor rolls are specially treated with shot blasting which are rotating on their axis to avoid marking off from the rod itself. 5. Loop formation is done by a Loop Rod roller system. 6. The steaming chamber is closed type made completely in stainless steel. 7. For low temperature steaming the chamber roof and entry, delivery slit is heated by steam coils preventing condensation and dripping on the fabric. 8. DIGIFIX, ATMOFIX and UNIFIX Steamers are equipped with special device steam saturator that conditions the steam, it passes through the water before being injected into steaming chamber. These particular characteristic of steam pre-conditioning which helps prevent and control the exothermic reaction of the fabric and of the printing paste, make the machine unique and our Temperature control system/ moisturising system for the said machines are the basis of great success achieved in the textile industries for Low Temperature Applications. 9. For high temperature steaming the EVOMAX and UNIFIX steamers are equipped with an efficient re-circulations system and heat exchanger using either thermic fluid or direct gas fire system which ensure uniform temperature in the chamber. 10. A special system to allow air to re-circulate in our RAPIFIX curing machine instead of steam permits polymerization treatment with hot air up to 160 ͦC. 11. Two big size access windows are provided on the front side and two small inspection windows on back side and also one small size window on the Drive arrangement platform. 12. Steam exhaust fan driven by variable speed AC motor, All fabric movements are driven by variable speed AC motor as well. 13. Automatic control PLC system for programming and monitoring of steam quantity, steam pressure, process time and temperature are optional with our “PRO” version of all the variants of Agers and Curing machines. 14. Our “LITE” versions of machines are also available for all variants of Agers and Curing machines for Manual operations which are also equipped with Modbus protocol and 7” HMI for easy operations.

Pasta

Get Price Quote

We deal with Italian Pasta. We do bulk delivery within Surat or near Surat city. Penne Rigate Pasta Pipe Rigate Pasta Fusilli Pasta Farfel (Bow) Pasta Macaroni Pasta Spaghetti

kitchen cookware

Get Price Quote

kitchen cookware, Aluminium Pressure Cooker, snack set, glass tea cup

Cooking Oil Extraction Machine

23,000 Per Piece

Fabric Loop Steamer

Get Price Quote

We are a prime Manufacturer and Exporter of Fabric Loop Steamer from India. Our range of Fabric Loop Steamers is designed in accordance with set industrial standards. Known for high performance and longer working life, our Fabric Loop Steamer is highly demanded in various industries. Advantages Easy to operateHigh performancePrompt after serviceVery low power consumption Specifications Speed up to 40 to 48 Meters/minTemperature range 130oC to 180oLow calorific requirement for steam super heating, as oil is directly burnt to super heat the steamDwell time 7 to 10 mints. Depending upon speed and model of the machineNo Explosion hazards like H.P AgerVarious models of 125-165-265-325 meter cloth contents with single or double width can be supplied

cooking pan

Get Price Quote

cooking pan, Drum Washer, Soft Flow Dyeing Machine, beam dyeing machine

Hard Anodized Cookware

Get Price Quote

Hard Anodized Cookware, High performance industrial coating

cooking pan

Get Price Quote

cooking pan, Jet Dyeing Machine, Drum Washer

Steamer

Get Price Quote

WASHING MACHINE, Dyeing Machine

Garment Steamer

Get Price Quote

Garment Steamer, textile processing machine, fabric steamer, loom machine

Loop Steamer

Get Price Quote

Loop Steamer

Sauce Pan

Get Price Quote

Sauce Pan, deep kadai, Stainless Steel Handi Pressure Cooker

Cookware

Get Price Quote

Cookware, Watches

Cookware

Get Price Quote

Cookware, Pressure Cooker

Gas Lighter

Get Price Quote

Water Bottle, Commercial Mixer, Electric Irons, Hand Blender, cooler stand

Dual Fuel Boiler

Get Price Quote

Dual Fuel Boiler, Steam Boiler, Long Tube Burner, Portable Gas Burner