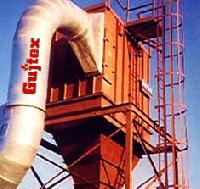

Pulse Jet Bag Filter

Get Price Quote

We are a prominent manufacturer and exporter of Pulse Jet Bag Filter based in india. the pulsejet bag fitter that we offer consists of filter cylinders (bags) enfolded in a metal housing. in operation, dust-laden air enters through the center of bag filter. either pressure or suction delivers the dirty air to the hopper. the fine particles travel upward and collect on the filter bags. the clean air passes through the bag and vents in to the atmosphere. a high-pressure jet of compressed air, which is directed through the bag, removes the dust, which is deposited in the hopper and is easily collected for disposal or recovered for use at timed intervals. anatomy of the pulsejet bag filter : the dust-tight pulsejet bag filter has three sections : a plenum at the top, a collector housing in the center, and a hopper at the bottom. a plenum (q) houses the blowtubes and supports for the solenoid valves. clean air or gas is released through the exhaust outlet ® in the plenum. the housing (m) contains the filter bag assemblies. below the housing is the hopper (o) which contains the inlet (n). a diffuser (t) in the hopper, adjacent to the inlet absorbs the impact of the high velocity dust particles and distributes the incoming air. pressure drop, that measures collector performance, is indicated by a d.p.gauge (s) connected at one end to the filter bag section and to the clean air plenum at the other end. a gujtex rotary airlock (p) is recommended as a discharge valve to handle the collected dust. filter cylinder assembly : the filter cylinders (bags) (a) slip over wire retainers (b). a bag clamp secures the bag-retainer assembly to the collar (c) of the venture nozzles (e), which are attached to a tube sheet (d). blowpipes (f) with orifice nozzles (g) are located above each row of filter bags so that the orifice nozzles are directly above the throat of each venture. the cleaning cycle : a signal from a remote sequence timer (h) actuates the opening of the normally closed solenoid or pilot valve (j). the opening of the solenoid valve decreases the pressure in the tube connecting the solenoid to the right angle diaphragm valve (k) causing the diaphragm valve to open. this permits a momentary jet of 100-psig air to flow from the air supply pipe (l) to blow tube, down each venture, and to each filter bag. all bags in a row are cleaned simultaneously.

Centrifugal Blower

4,900 Per Piece

Best Deals from Dust Collector Parts

Fume Exhaust Blower

Get Price Quote

1 Piece(s) (MOQ)

High efficiency low noise equipment installed in residential building. we are regular supplies for aerofoil bladed kitchen fume exhaust blowers across india & abroad

Bag Filter

Get Price Quote

Bag filter system is designed for optimum filtration performance. Its range provides filtration solution for a broad variety of fluid applications in the process industry. They are particularly useful for filtering large volumes of high viscosity liquids. Bag filter is constructed of filter housing, filter bags, internal cage to support bags, positive sealing arrangement & choice of end connections. The internal support ensures bags will not burst as high differential pressures build up during operation. FEATURES High flow rates and low pressure drop. High dirt holding capacities. Efficiency as high as 98% and dust emission as low as 5 mg/Nm3. Easy to operate and low maintenance. Large area & heavy duty baskets. Housing made from stainless steel are mirror polished to resist adhesion of dirt and scale. Carbon steel housing are sand blasted, epoxy coated & finally painted with two coats of synthetic enamel. Multiple bag filter / Duplex bag filter / Jacketed bag filter unit designs.

Centrifugal Blower

19,000 Per UNIT

Treema Cyclone Dust Collector

500,000 - 20,000,000 Per Piece

1 Piece (MOQ)

mechanical dust collectors

Get Price Quote

We are offering mechanical dust collectors. » adequate to coarse dust content gas capacity (100-1,00,000 ft.min.) adequate to high dust concentration. » trouble free operation long life » high collection efficiency (coarse dust) » low initial cost. » no maintenance required till 4-5 years » power consumption 0.5 hp » self discharging facility.

backward curved blower

Get Price Quote

The single Thickness Backward Curved Impeller is highly Efficient and only slightly less Efficient than its Aerofoil Counterpart. It has ideal Aerodynamic characteristics with maximum Design efficiency upto 82.4 %. It can be used for clean air or medium concentrations for medium to high pressure industrial applications. 9 different series for varying wheel designs allow flexibility in selection. This Design is uited for Harsh process requirements and is the most preferred choice for majority of applications. With years of application oriented experience and latest Manufacturing facilities, we manufacture these Impellers within close tolerences matching exact blade profiles using mechanized welding procedures. With welding distortion Management, maintaining minimal impeller run out before dynamic balancing and with special handling of Impeller, SYMBIOSIS delivers world class fans and blowers for your Critical applications Our Blowers are truly SYMBIOTIC to your process. Think of Air…… Think of SYMBIOSIS Blower. We offer the Backward Curved Centrifugal fan in multiple sizes, arrangements, construction classes, impeller and housing widths. Whether standard or custom, each SYMBIOSIS Industrial Fan is designed and built with unmatched quality and backed by responsive service

Pulse Jet Bag Filter

Get Price Quote

Self Supported Chimney, Oil & Gas Fired Thermic Fluid Heater

Cashew Dust Collector

Get Price Quote

Cashew Dust Collector, Conveyor Belt System for Cashew Processing Steps

Filter Bags

Get Price Quote

Replacement Filter Bag

Get Price Quote

Replacement Filter Bag, micron cartridge filters, Industrial Evaporators

Bag Filters

Get Price Quote

Chimney, Steam Boiler, Thermic Fluid Heaters

Pulse Jet Dust Collector Valve

Get Price Quote

Pulse Jet Dust Collector Valve, Air & Oil Filter, Festo Roller Lever Valve