EK-1518 Spin On Oil & Fuel Filter Kit

491 Per piece

24 piece (MOQ)

Bag Filter

250,000 - 2,000,000 Per Piece

1 Piece(s) (MOQ)

Clients can avail from us Bag Filter that is required for boiler. The Bag Filters, offered by us, are made from quality materials in compliance with the industry set norms and standards. The Bag Filters can be availed in different specifications from us. We are a preeminent name as Bag Filter Manufacturer and Supplier in Gujarat (India).

Best Deals from Filters

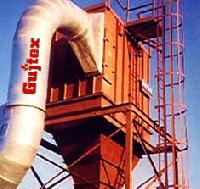

Pulse Jet Bag Filter

Get Price Quote

We are a prominent manufacturer and exporter of Pulse Jet Bag Filter based in india. the pulsejet bag fitter that we offer consists of filter cylinders (bags) enfolded in a metal housing. in operation, dust-laden air enters through the center of bag filter. either pressure or suction delivers the dirty air to the hopper. the fine particles travel upward and collect on the filter bags. the clean air passes through the bag and vents in to the atmosphere. a high-pressure jet of compressed air, which is directed through the bag, removes the dust, which is deposited in the hopper and is easily collected for disposal or recovered for use at timed intervals. anatomy of the pulsejet bag filter : the dust-tight pulsejet bag filter has three sections : a plenum at the top, a collector housing in the center, and a hopper at the bottom. a plenum (q) houses the blowtubes and supports for the solenoid valves. clean air or gas is released through the exhaust outlet ® in the plenum. the housing (m) contains the filter bag assemblies. below the housing is the hopper (o) which contains the inlet (n). a diffuser (t) in the hopper, adjacent to the inlet absorbs the impact of the high velocity dust particles and distributes the incoming air. pressure drop, that measures collector performance, is indicated by a d.p.gauge (s) connected at one end to the filter bag section and to the clean air plenum at the other end. a gujtex rotary airlock (p) is recommended as a discharge valve to handle the collected dust. filter cylinder assembly : the filter cylinders (bags) (a) slip over wire retainers (b). a bag clamp secures the bag-retainer assembly to the collar (c) of the venture nozzles (e), which are attached to a tube sheet (d). blowpipes (f) with orifice nozzles (g) are located above each row of filter bags so that the orifice nozzles are directly above the throat of each venture. the cleaning cycle : a signal from a remote sequence timer (h) actuates the opening of the normally closed solenoid or pilot valve (j). the opening of the solenoid valve decreases the pressure in the tube connecting the solenoid to the right angle diaphragm valve (k) causing the diaphragm valve to open. this permits a momentary jet of 100-psig air to flow from the air supply pipe (l) to blow tube, down each venture, and to each filter bag. all bags in a row are cleaned simultaneously.

Industrial RO Water Filter

Get Price Quote

Industrial RO Water Filter, Water Purifier, Water Purifier Spare Parts

Antioxidant Filter

Get Price Quote

Antioxidant Filter, Inline Filter, glass filling machine

Kemflo Sediment Filter

Get Price Quote

Kemflo Sediment Filter, antiscalant balls, water motor, high pressure switch

Carbon Filters

Get Price Quote

Pressure Sand Filters, Uv System, Disc Filters

Diesel Filter

Get Price Quote

Diesel Filter, agriculture implement, oil filter gear part

Water Filters

Get Price Quote

Water Filters

Pulse Jet Bag Filter

Get Price Quote

Self Supported Chimney, Oil & Gas Fired Thermic Fluid Heater

Bag Filters

Get Price Quote

Thermal Fluid Vaporizer, Bi Drum Boilers, mechanical dust collectors