Turbo Air Ventilator

Proper ventilation is necessary in all buildings, which are extremely susceptible to condensation and heat transfer. Generally, hot or stale air will not exhaust through an opening into which wind can blow. Therefore, regular static ventilators , which allow outside wind to enter in the shed because of over design or location on the roof, cannot be expected to exhaust because they back draft. An efficient means of extracting warm and stale air is through roof mounted turbo air ventilators , which create positive draft, removes hot gases, obnoxious fumes, bad odor, enhances ventilation . Adequate low level provision for the entry of fresh air at ambient temperature should be provided.Our Turbo Air Ventilator is manufactured based on computer aided designed which provides optimum air ventilation . These Turbo Air Ventilator are very light weight, high corrosion resistant, maintenance free, energy saving and provides efficient operation vent in a breeze of wind. Turbo Air Ventilator are designed in 2 size 21 & 24 inches fitted with ball bearing & stainless steel shaft to provide almost zero noise operation. These Turbo Air Ventilator are fabricated with special grade aluminium to anodized specification. The Teflon self lubricated impregnated bearing gives a smooth rotation and maintenance free long life

...more

TILE MAKING ROLL FORMING MACHINE

Profile of Tile Making Roll Forming Machine Feeding width:1000mm Effective width:840mm Material thickness: 0.4-0.8mm Process flow of Tile Making Roll Forming Machine Decoiling feeding forming cutting production Manual Decoiler Material coil inner diameter: 450mm-700mm Max coil width: 1000mm Carrying capacity: 5T Forming Device Number of forming steps: 18 steps Shaft material: 45 steel with harden treatment, outer diameter 85mm Roller material: 45steel Main motor power: 15kw Forming speed: 8-10m/min Voltage: 220V/50Hz/3 phrase Cutting Device hydraulic cutter blade, puncher and mold material: Cr12 steel with quenched treated 60-62C cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor. Controlling Device screen: 5.7 inch Delta screen from Taiwan PLC: Delta DVP14ES from Taiwan coder: Delta Hydraulic Advanced hydraulic system from Taiwan Power: 11kw Simple output frame simple frame weld bu 8 U bar, 1 pcs of 3m

Voltage : 220V/50Hz/3 phrase

...more

strip making machine

The other model is fixed width hand operated precision strip cutting machine. This machine is usually preferred by the customer making hollow balls and for those, you require very precise fixed width strips of one or two sizes only. The cutters for this machines are designed in such a way that they fit into one another like male-female type roll to give extremely accurate width strips.

...more

steel roofing sheet

Colour Coated Profile Roofing Sheet : Color Coated Galvanised Galvalume Sheets trapezoidal profiles are used for widely diverse applications. As they have large range of geometric designs, they offer variety of architectural possibilities. Color Coated Galvanised Galvalume Sheets trapezoidal profiles are supplied not only in different sections and thickness but also in various heights and required dimensions. They are suitable for use as Roof and Wall Panels , in single or double shell construction.The steel roofing sheet are galvanized and coated with RMP/SMP/HDP/PVF2 and the basic steel used in the processing are galvanized as per are 277 with zinc coating around. These steel roofing sheet are available in different sizes as per client specification.We do manufacture curve steel roofing sheet which are also called as crimp curve upto 8 metres. We do also manufacture supporting accessories which are necessary for an industrial shed namely: Water gutter Down spot Barge cap Ridges Corner Flashings Drip trim Galvalume SheetsWe specialize in PPGI and PPGL Sheets which are made of world class raw material complying with the international standards. Because of its excellent corrosion resistance, these steel roofing sheet have become the most preferred material for various construction purposes, particularly roofing and wall cladding. Coated steel roofing sheet is a unique building material that combines the strength of steel with excellent corrosion protection of zinc or zinc/aluminum alloy coatings. It can be punched, pressed, roll formed and joined into a countless number of structural and decorative building products. Our PPGI and PPGL Sheets are available in various colors – Sky Blue, Royal Blue, Taurus Blue, Off White Terra Cotta Red, and Mist Green etc. Pre Painted Galvanized Sheets Pre Color Coated Galvalume Sheets Bare Galvalume Sheets

...more

Steel Bending Machine

Bending Machines consists of a basic machine that can be adjusted with little effort and used for a variety of bends. A simple plug-in system supports quick and easy exchange of tools. The Bending Machines consists of a CNC-operated side stop, a work bench, and software for programming and operating. Its modular construction offers an affordable entry into the bending technology, because after an initial investment this bending machines can be customized and extended later on without any conversion. That means this bending machines delivers a bending stroke, the tool determines the kind of bending.

...more

shutter rolling machine

Manufacturing of this range of Rolling Shutter Pati Forming Machines, involves using the finest raw materials and modern machines, in compliance with the industry set norms and guidelines. Owing to this, the offered range has a superior functionality and a commendable resistance to corrosion. Its superior functional life, reasonable pricing and user friendly nature, make the range highly asked for.

...more

Sheet Forming Machines

We are manufacturing and exporting of Corrugated Sheet Roll Forming Machine. These products are designed to reduce man power and stable steel base design. These machines are used in industrial sectors. Corrugated Sheet Roll Forming Machine are equipped with various features including en31 material hafts, elecon gear box, abb motors etc. Corrugated Sheet Roll Forming Machine can process sheets of any required length which can be easily programmed.

...more

roofing steel sheet

The steel roofing sheet are galvanized and coated with RMPSMPHDPPVF2 and the basic steel used in the processing are galvanized as per are 277 with zinc coating around. These steel roofing sheet are available in different sizes as per client specification.

...more

Roofing Sheet Machine

We manufacture high performance Roof Sheet Crimping Machine. These Roof Sheet Crimping Machine are mainly used for the sheet crimping in the industries like automobile, beverage, food, fast moving consumer goods, packaging, print and publishing industry. Our Roof Sheet Crimping Machine can be customized to be controlled with an automatic ejection technology. This Roof Sheet Crimping Machine is used to crimp the formed corrugated sheets into horizontal stripes through hydraulic crimping mold. The distance between each press will decide the curvature of the arch. It is suitable for edge of buildings, parking garage, pavilion and various round roofs of buildings. This Roof Sheet Crimping Machine can crimp both ends of roofing sheet.

...more

Roofing Sheet Cutting Machine

We are manufacturing and exporting of Corrugated Sheet Roll Forming Machine. These products are designed to reduce man power and stable steel base design. These machines are used in industrial sectors. Corrugated Sheet Roll Forming Machine are equipped with various features including en31 material hafts, elecon gear box, abb motors etc. Corrugated Sheet Roll Forming Machine can process sheets of any required length which can be easily programmed.

...more

Roof Forming Machine

We are manufacturing and exporting of Corrugated Sheet Roll Forming Machine. These products are designed to reduce man power and stable steel base design. These machines are used in industrial sectors. Corrugated Sheet Roll Forming Machine are equipped with various features including en31 material hafts, elecon gear box, abb motors etc. Corrugated Sheet Roll Forming Machine can process sheets of any required length which can be easily programmed.

...more

ROLLING SHUTTER PATTI MAKING MACHINE

Manufacturing of this range of Rolling Shutter Pati Forming Machines, involves using the finest raw materials and modern machines, in compliance with the industry set norms and guidelines. Owing to this, the offered range has a superior functionality and a commendable resistance to corrosion. Its superior functional life, reasonable pricing and user friendly nature, make the range highly asked for.Features: User friendly Longer functional life Impeccable functionality

...more

rolling shutter motor

Rolling shutter motor are widely used in super market, warehouse, garage, bank, factory etc. It is not only effective for anti-theft but also has action of self locking and drop protection. Rolling shutter motor has very low consumption due its unique design. These rolling shutter motor are safe, reliable & very easy to maintain. Rolling shutter motor are widely used in super market, warehouse, garage, bank, factory etc. It is not only effective for anti-theft but also has action of self locking and drop protection. Rolling shutter motor has very low consumption due its unique design. These rolling shutter motor are safe, reliable & very easy to maintain.We are professional manufacturer of Rolling Door Motor , Tubular Motor, Micro Switch and semiconductor component separator, etc. After years of practical experience, efforts of all colleagues, the support of customers and suppliers, now we have Mechanical & Electrical Department, Electronic Components Department and Integrated Department of Market Operation. There are more than 40 series products, with over 500 kinds of specifications. Mechanical & Electrical products are widely used in shopping malls, hotels, warehouses, banks, factories and other buildings rolling door opening and closing; Electronic Components are mainly used in home appliances, industrial control, automotive electronics and other areas. Main products: Rolling Door Motor , Roller Shutter Motor , Garage Door Motor , Rolling Shutter Motor , Automatic Door Opener , Tubular Motor, Micro Switch, Tip Over Switch, Tilt Switch, Safety Switch, Bridge Rectifier, etc. Superior Service:Being a professional manufacturer for many years, we always supply quality product at competitive prices with superior service. We keep the principle of “Quality First, Customers Supreme” and always try to meet customers’ Requirements at any time. Any inquiries will be replied within 1 business day. Quality Assurance: We have QC department to make inspect every step of production, so we can make sure good quality products for customers. Feature of product 100% copper material inside the motor, so it has a larger capacity and durable than other rolling shutter motor . Overheat protection:The rolling shutter motor is with overheating protecting equipment. If the temperature up to 110, the power supply will be cut off automatically to protect the motor. Till the temperature down to 70, it can be used again. Mechanic Limit switch adjusts the door position in both “up” and “down” precisely and safety Battery-up: the rolling shutter motor driver exchanges to supply from 220 V AC to 24 V DC Operated by manual chain when power off. Press the rolling door ’s button operation, power-driven make shutter open and close safely, positioning accurate and reliable When the power off,the hand chain elevating Rolling Door or hand lever gravity separation by falling closed Rolling Door . Motor with overheated protector, providing overheating protection function. Remote control adopts button transmission mechanism,limit control sensitive, sasy to adjust, Remote control range can reach up to over 10 meters. The error of positioning accuracy is less than 5 millimeters Transmission mechanism has reasonable design, advanced technology, The gears are not easy to wear, durable operation, low noise and small shaking The brake organizations adopt hoof from production device, friction facings formulations adopts advanced friction accuracy error is less than 10 millimeters. Rolling door itself can provide limit protection when it is falling.(constant speed function) Rolling shutter motor starting torque, over load-ability. Electric Roller Shutter machine for short-time duty(S2), continuous running time is less than 5 min. Anti-theft function well with radio remote support.

...more

Roller Shutter Motor

Rolling shutter motor are widely used in super market, warehouse, garage, bank, factory etc. It is not only effective for anti-theft but also has action of self locking and drop protection. Rolling shutter motor has very low consumption due its unique design. These rolling shutter motor are safe, reliable & very easy to maintain. We are professional manufacturer of Rolling Door Motor, Tubular Motor, Micro Switch and semiconductor component separator, etc. After years of practical experience, efforts of all colleagues, the support of customers and suppliers, now we have Mechanical & Electrical Department, Electronic Components Department and Integrated Department of Market Operation. There are more than 40 series products, with over 500 kinds of specifications. Mechanical & Electrical products are widely used in shopping malls, hotels, warehouses, banks, factories and other buildings rolling door opening and closing; Electronic Components are mainly used in home appliances, industrial control, automotive electronics and other areas.

Voltage : 220 V AC to 24 V

...more

Roll Forming Machine

We are manufacturing and exporting of Corrugated Sheet Roll Forming Machine . These products are designed to reduce man power and stable steel base design. These machines are used in industrial sectors. Corrugated Sheet Roll Forming Machine are equipped with various features including en31 material hafts, elecon gear box, abb motors etc. Corrugated Sheet Roll Forming Machine can process sheets of any required length which can be easily programmed. D coiler 5 ton cap. Entry Gate with Roll Forming Line with 18 stations, 10 H.P. electrical. Control Panel semi auto Cutting Unit (Hydro.) Technical Specifications of Roll Forming Machine Maximum sheet width that can be formed : 1250 mm Maximum sheet thickness in CRCA Strips that can be formed : 1.2 mm Horizontal distance between shafts : 500mm Number of forming stations : 16 nos. Total HP for Line : 8 Speed of the machine : 10 -14 mt / mint Size of machine : 9500 x 1700 x 1100 mm Entry GateEntry gate will be provided for movement of sheet to roll former.Main BaseThe main base is MS fabricated structure and adequately ribbed to minimize the distortion. It is accurately machined on top and bottom surfaces the threaded holes are made on the bed for positioning the stands.Mill stands (Station)The stands are mounted on the bed of the machine the line alignment can be easily done due to guide ways arranged on the bed of the machine. Each forming head consists of a fixed housing and sliding type out board housing. The mill stands will be arranged to locate shafts mounted on taper bearings. For the top shafts the bearings are housed in the cartridge type bearing blocks. The bottom shaft bearings are located in the bored machined in the housings. The bottom arbors are fixed in position whereas the top arbors along with cartridge blocks could be raised or lowered in vertical guides machined in housings.Roll shaftsThe roll shafts dia. 70mm will be manufactured from quality steel and will be keyed to locate tooling.DriveThe drive to the roll former will be by means of a chain. The main drive will be provided by means of 10 HP motor.ToolingOne set of Tooling with EN grade will be from imported material suitable for your machine as standard supply. The same is involved in operations like rough machining, key way, rough profiling, profile machining and inspection with final template for above.Cutting Unit (Hydro)Hydraulically operated power pack along with cutting die with 3 HP electrical.

...more

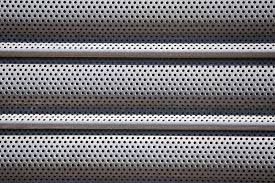

Perforated Rolling Shutters

Perforated Rolling Shutters that are generally used in the buildings to let air or water enter andor leave. Perforated Rolling Shutters gives full window protection and ventilation. Perforated Rolling Shutters are cost effect way of providing a secure closure to small or large openings. Perforated Rolling Shutters are the most effective options for shops, power generator rooms, transformer rooms and many commercial places. Perforated Rolling Shutters are free from any king of corrosion and robust in nature which makes them suitable for almost all the applications. These perforated shutters serve as a great solution for the shopkeepers and business owners as they allow security to the closed premises whilst allowing customers to see inside when the area is backlit.

...more

perforated rolling shutter

Perforated Rolling Shutters that are generally used in the buildings to let air or water enter and/or leave. Perforated Rolling Shutters gives full window protection and ventilation. Perforated Rolling Shutters are cost effect way of providing a secure closure to small or large openings. Perforated Rolling Shutters are the most effective options for shops, power generator rooms, transformer rooms and many commercial places. Perforated Rolling Shutters are free from any king of corrosion and robust in nature which makes them suitable for almost all the applications. These perforated shutters serve as a great solution for the shopkeepers and business owners as they allow security to the closed premises whilst allowing customers to see inside when the area is backlit.

...more

panel roll forming machine

Profile of Panel Roll Forming Machine Feeding width:1000mm Effective width:840mm Material thickness: 0.4-0.8mm Process flow of Panel Roll Forming Machine Decoiling feeding forming cutting production Manual Decoiler Material coil inner diameter: 450mm-700mm Max coil width: 1000mm Carrying capacity: 5T Forming Device Number of forming steps: 18 steps Shaft material: 45 steel with harden treatment, outer diameter 85mm Roller material: 45steel Main motor power: 15kw Forming speed: 8-10m/min Voltage: 220V/50Hz/3 phrase Cutting Device Hydraulic cutter blade, puncher and mold material: Cr12 steel with quenched treated 60-62C cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor. Controlling Device screen: 5.7 inch Delta screen from Taiwan PLC: Delta DVP14ES from Taiwan coder: Delta Hydraulic Advanced hydraulic system from Taiwan Power: 11kw

Power : 11kw

Voltage : 220V/50Hz/3 phrase

...more

motorised rolling shutters

We make motorised rolling shutters by adding electrical rolling shutter motors making it easy to operated . These automatic rolling shutters are the most popular among all the types of rolling shutters . These are characterized by robust structure and durability. We make use of high strength metal in the fabrication of motorized automatic rolling shutters .Owing to these features, our rolling shutter acts as a shield and protection against burglary and weather effects. These rolling shutters require low maintenance and offer easy operation ensuring total customer satisfaction.Our motorised rolling shutters are suitable for shops, showrooms and other commercial buildings. Whether they are installed outside or inside, these motorised rolling shutters the perfect choice for any structure. Get your desired specification of rolling shutters from us at industry leading prices.

...more

industrial roofing shed

Our competent professionals allow us to manufacture a unique range Roof Shed . These products are manufactured using quality approved raw material, which is procured from the most trusted vendors of the market. We also offer a customized range of industrial roofing shed , depending on the diversified demands of our clients. Industrial Roofing Sheds We offer fabric for water proofing of Industrial Roofing Sheds which is widely used in civil construction, industrial construction, etc. These fabrics are made from excellent raw materials that impart requisite quality attributes to this range.The pivotal features of Industrial Roofing Sheds are as follows: High tensile strength Corrosion resistant Less maintenance Parking Roof Shed :We manufacture a comprehensive range of Parking Roof Shed in standard and customized sizes and dimensions. These parking roof shed are made using high quality material and therefore have good resistance to adverse weather conditions and require less maintenance. Moreover, our light weight parking sheds are easy to install and are available at reasonable prices. FRP Roof Shed : We are engaged from many years in manufacturing a comprehensive range of FRP Roof Shed . These FRP Roof Shed are widely used in houses, restaurants and shops. We elegantly design these products using superior quality fiber glass.Some of the distinctive features of our FRP Roof Shed are as follows: Durability High tensile strength Resistance to adverse conditions

...more

Industrial Crane

We are equipped and specialized in designing, manufacturing and installing industrial cranes and hoists . We provide variety of solution in material handling with our range of standard equipment as well as custom engineered systems.Our industrial cranes are designed in accordance with IS Standard specifications. Top running industrial cranes run on elevated runway system along length of a factory and provide 3 axes of hook industrial cranes are in use in a wide range of lifting applications from the lightest duty to serve industrial applicationFeatures of Industrial Cranes Low Dead Weight : Reduces cost of supporting structure. Minimum Headroom : reduce building cost. Wide selection of operation speeds. All bolted construction for ease in assembly. Steel Construction:Steel confirming to IS 2062 of or equivalent are use in the manufacturing of the main load bearing members. The girders are not only designed for deflection and strength but also account is taken for natural time of vibration and damping, This will avoid vibration in the industrial crane girders and other industrial crane components.End Carriages / End Trucks:The industrial crane end trucks are manufactured either standard rolled steel section or welded plate box section type and are assembled to ensure alignment of bearing and axles. Twin drive arrangements are normally standard. Central drive arrangements are also available on request. Main cross girders to end trucks connection are bolted to ease in assembly. Rubber buffers are standard on all end trucks to reduce impact when a moving industrial crane or trolley reaches the end of its permitted travel or when two moving cranes or trolley come into contact.Hoisting Machinery:The hoisting machinery / crab consists of heavy duty industrial type standard wire rope hoist .Motors & Brakes:All motors used in the industrial crane are specially designed for industrial cranes and hoist duty applications. All trolley and drive motors have suitable AC/DC brakes as standard equipment with smooth running properties

...more

HYDRAULIC FULLY AUTOMATIC FORMING MACHINE

The Chart of Process flow of Hydraulic Fully Automatic Forming Machine Decoiling, feeding, pressing and forming the shape, measure the length, cutting, receiving the platesThe Hydraulic Fully Automatic Forming Machine includesManual decoiler, Main forming machine , Hydraulic cutter, forming machine

...more

Grill Rolling Shutter

We manufacture wide range of Grill Rolling Shutter . These rolling shutters allow full ventilation , and our display is visible for our window shopper. These could also serve as ventilation and security tool. Our grill rolling shutter can be motorized for smooth and easy operation. Additionally, these rolling shutters have easy release for manual operation in the case of power failure.Our grill rolling shutter are well know for their perfection & robust. Moreover, these grill rolling shutter can be made as per the requirements of the customers. These grill rolling shutter are best used for shops, hotels, restaurants, banks, offices and so on.

...more

Glazed Tile Forming Machine

The line includes: Manual decoiler, Main forming machine , Hydraulic press forming unit, Hydraulic system, Electrical control system, Hydraulic cutter, Normal receiving stand.Technical specifications of Glazed Tile Forming Machine : Manual decoiler Coil inner diameter: 450mm-650mm Coil outer diameter: 1100mm Maximum width of coiling: 1250mm Maximum weight of loading: 5000kg Glazed Tile Forming Machine Number of forming rollers: 10 groups Material of shaft: 45# steel adjustable treatment. Outer diameter 70mm Material of roller: 45#steel, plating hard chrome on the surface, rigidity HR55°-57° Main motor power: 5.5kw Speed of forming: 3m/min Stand: 300# steel welding The plating chromium of rollers’ surface: 0.05mm Thickness of the steel: 0.4-0.6mm Chains: 1 inch Thickness of wall plate: 12mm Dimension of the machine: About 7.5m*1.5m*1.5m Weight of the machine: 5500KG Hydraulic Cutter Material of blade: Cr12 mold steel with quenched treatment 60-62°C Cutting system: adopt advanced hydraulic drive, after forming automatic cut, no distort, no wasting high safe factor. Function and structure: cutting the forming sheet. Hydraulic Drive:Function: press the mark on the steel plate, make it look like steel tile.Electrical control system: The Brand of display: 5.7 inch The main computer (PLC): Tai Da DVP14ES Function and operation: Control the starting ,operation and stopping of the whole line, including distribution section, operation table, counting instrument. Use PLC to control, set and adjust the length. Hydraulic system: Adopting advanced hydraulic system of Tai Wan Power: 3KW Function: apply power for cutting machine

...moreBe first to Rate

Rate ThisOpening Hours