Wall Panel Roll Forming Machine

• Thickness:0.4-0.8mm • Machine for Wall & Roof • Coil width:1000mm,1250mm,etc Profile • Feeding width:1250mm • Effective width:1000mm • Material thickness: 0.4-0.8mm Process flow • Decoiling • feeding • forming • cutting • production Manual Decoiler • Material coil inner diameter: 450mm-700mm • Max coil width: 1250mm • Carrying capacity: 5T Forming Device • Number of forming steps: 13 steps • Shaft material: 45 steel with harden treatment, outer diameter 70mm • Roller material: 45steel • Main motor power: 15kw • Forming speed: 8-10m/min • Voltage:380V/50Hz/3 phrase Cutting Device • hydraulic cutter • blade, puncher and mold material: Cr12 steel with quenched treated 60-62C • cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor. Controlling Device • screen: 5.7 inch Delta screen from Taiwan • PLC: Delta DVP14ES from Taiwan • coder: Delta Hydraulic • Advanced hydraulic system from Taiwan • Power: 3kw Simple output frame • simple frame weld bu 8 U bar, 1 pcs of 3m Packing • Container packing of the line suitable for overseas shipping • The subject can be loaded in one 40’ GP container. • Packing style: Naked and covered by plastic film, spare parts and some small parts packed in wooden box. Assemble, train the machine • It is free to assemble and train the machine, but the buyer must pay for the round-trip airplane ticket, and arrange accommodation during that time Maintain It is free to maintain the machine the first year after you buying, include changing the main components. The first year hence, you will pay for our technician $50/day to maintain the machine. And its component is not free, if you need to get it from us. (The buyer should supply airplane ticket and accommodation, if he need maintain).

...more

Turbo Ventilators

Turbo ventilators are designed and engineered to exhaust Industrial pollutants such as smoke, dust, poisonous gases, humidity, fumes, heat and many more invisible irritants from the covered area. Turbine Ventilator provides a safe, cool, healthier and more controlled environment by removing the entrapped heat and industrial emission ensuring the health of workers, thus contributing to an increase in workers' productivity. Turbo Ventilators provide energy free cooling and fresh air throughout the year, this product is a Wind operated Ventilator installed on the roof and is rotated by the Wind, the stale air inside is exhausted through the vanes and a natural inward flow of fresh air is boosted. Turbine Air Ventilator works without electricity, it runs on wind velocity and it works 24 hours a day and 365 days a year.This system functions and performs with the unlimited energy source like wind energy thus saving running cost exhaust fans, wiring, maintenance etc.Wind turbo ventilators does not require operating time, it continuously rotate with the wind, removes moisture laden air in the winter and extremely hot air in the summer.Turbo ventilators are provided for maintaining healthy environment inside the building. Ventilators made from light-weight Aluminum & Stainless Steel are specially designed. These turbo ventilators are also maintenance free. Advantages • Easy to install and can be fitted to any type of roofing. • Can be configured to meet required fresh air changes. • Low maintenance cost since the system operates on wind power. • Weather and storm proof. • Economical and Ecological. • Maintenance free & durability. Application • Industries. • Godowns and warehouses. • Theaters and Community halls. • Hospitals and schools. • Factories. • Auditoriums. • Power houses and lift rooms.

...more

Trapezoid Roof Roll Forming Machine

We are specialized in manufacture and design rolling form machine and automatic production lines. The machines are mainly used in the following areas: • In building trade : to product C&Z shape purlin, loading bearing plate, wall or roof steel plate, high-grade colorful decorating and protecting steel plates; • In environment line: to make anode plate and cathode plate for dust catcher; • In transport line: to make freeway guardrail plate, vehicle board; • In logistics line: to product goods shelf pillar, holding beam, joist; • In Electrical equipment line: to make cable bridge, box pillar and others thin wall rolling form materials. Such as goods shelf board, kinds of box panels etc. • We also can supply other machine lines such as coiled, uncoiled, check level, end long cutting, across cutting, buttress. Our machines characteristics are high efficiency, high flexibility and low production cost. All of our machines have competitive price and quality. We will try our best to make and supply you the suitable machine for you accordance with your requirements. We can services for you from the begging to the end. Believe you will be satisfied with our best quality equipment and good sevice.

...more

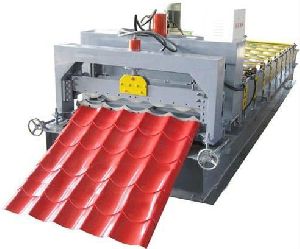

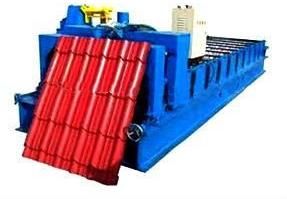

tile making machines

• Lowest price • Best service • Easy operation • Beasutiful outlook Profile • Feeding width:1000mm • Effective width:840mm • Material thickness: 0.4-0.8mm Process flow • Decoiling • feeding • forming • cutting • production Manual Decoiler • Material coil inner diameter: 450mm-700mm • Max coil width: 1000mm • Carrying capacity: 5T Forming Device • Number of forming steps: 18 steps • Shaft material: 45 steel with harden treatment, outer diameter 85mm • Roller material: 45steel • Main motor power: 15kw • Forming speed: 8-10m/min • Voltage: 220V/50Hz/3 phrase Cutting Device • hydraulic cutter • blade, puncher and mold material: Cr12 steel with quenched treated 60-62C • cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor. Controlling Device • screen: 5.7 inch Delta screen from Taiwan • PLC: Delta DVP14ES from Taiwan • coder: Delta Hydraulic • Advanced hydraulic system from Taiwan • Power: 11kw Simple output frame • simple frame weld bu 8 U bar, 1 pcs of 3m Packing • Container packing of the line suitable for overseas shipping • The subject can be loaded in one 40’ GP container. • Packing style: Naked and covered by plastic film, spare parts and some small parts packed in wooden box. Assemble, train the machine • It is free to assemble and train the machine, but the buyer must pay for the round-trip airplane ticket, and arrange accommodation during that time Maintain It is free to maintain the machine the first year after you buying, include changing the main components. The first year hence, you will pay for our technician $50/day to maintain the machine. And its component is not free, if you need to get it from us. (The buyer should supply airplane ticket and accommodation, if he need maintain). Component and Function: • Sheet guiding equipment: Using guiding equipment of leader sliding block style. The width and the left or right position can be adjusted only by adjusting the leader, then the sliding block can realize left or right movement. • Mainframe Transmission: Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet. • Roll forming system: The main frame of machine is welded separately and the outside wall is connected by screw after being roto-blasted on the surface. The rollers are surface-chrome plated after being machined by the exact machine tool.

...more

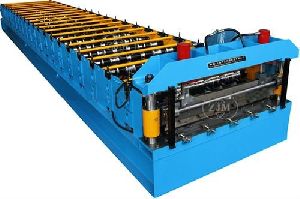

STEEL ROOFING SHEET FORMING MACHINE

• GI or colored steel • Trapezoidal or corrguated tile drawing • PLC controlled • Two year guarantee • Hydralic system Parameter • Suitable to process:Colored Steel plate, galvanized board • Width of the plate:1000/1250mm • Rollers:13-18rows • Rolling material: Forging Steel 45 • Rolling galvanization thickness:0.05 mm • Material of the cutting blade :Cr12 • Hydraulic oil :40 • Dimensions:7*1.45*1.51m • Power:3+4kw • Thickness of the plate:0.3-0.8mm • Productivity:0-8m/min • Diameter of the roller:70mm • Weight:About 3 T • Voltage: 380V 50Hz 3PH • Processing precision : within 1.00mm • Equipment components: Man-made uncoiler, Roll forming machine, compture control system, hydraulic control system, cutting • Transportation:one complate equipment need one 40feet container to hold

...more

Steel Roofing Shades

We are offering steel roofing shades. Our roof repair & maintenance division was created specifically to address the needs of businesses and homeowners for fast, professional roof repair services and to reduce the occurrence of leaks and the damage water can cause. very few roofing contractors offer a dedicated division with the sole purpose of repairing and maintaining roofs. Because our roof repair & maintenance division is specialized, you can be assured of quality, detailed workmanship in accurately surveying and addressing your immediate needs as well as determining what should be done so you can experience the maximum life expectancy of your roof.

...more

Steel Roof Forming Machine

The steel roofing machine is used to roll form steel roof for peb buildings. The steel roofing machine is controlled by PLC with high accuracy to roll form steel steel roofing machine, steel sheeting machine, steel roof forming machine. The steel roofing machine consists of one ecoiler, one roll former, and one stacker. The steel roofing machine is used to roll forming the steel sheets into profiled roof for pre-engineering building (PEB). The profiled steel sheets with an enhanced strength can be used for long term roofing system.

...more

shutter profile machine

Shutter profile machine is used to manufacture heat-preserving panels. Its products(heat preserving panels) are both widely used in construction area, which have reliable performance, high quality and beautiful appearance.

...more

sheet making machine

Sheet making machine Suitable to process:Colored Steel plate, galvanized board. Width of the plate:1000.1220.1250.mm. Rolling material: Forging Steel 45#. Material of the cutting blade :Cr12.

Voltage : 380V 50Hz 3PH

...more

Roofing Sheet

We are offering roofing sheet. your roof is the most important part of the building to keep in top shape, because without a solid, leak-free roof, your entire building is at risk of damage from the elements. That’s why sant roof pvt. Ltds motto is "where concern is over head". we specialize in offering a range of high quality roofing sheets, available in different sizes and standards to meet clients requirement. These sheets are available in various standards and thus find application like industries, swimming pools, parking area of multi stored building and shopping complex, gardens, terrace, open to sky areas etc. These sheets are designed in various attractive shades to enhance the exterior of homes, offices, and various other buildings.

...more

Roofing Sheet Making Machine

Roofing sheet making machine Working speed of Roll Shutter Forming Machine: 10-12m. Min. Total weight of Roll Shutter Forming Machine: About 4MT . Voltage: 380V 3 phase 60 Hz or as per the customers' requirements.

...more

Roofing Sheet Machine

Roofing sheet machine of one ecoiler, one roll former, and one stacker. The steel roofing machine is used to roll forming the steel sheets into profiled roof for pre-engineering building (PEB). The profiled steel sheets with an enhanced strength can be used for long term roofing system.

...more

roofing sheet forming machine

Roofing sheet forming machine Its products(heat preserving panels) are both widely used in construction area, which have reliable performance, high quality and beautiful appearance.

...more

Roofing Sheet Cutting Machine

Roofing sheet cutting machine It produces a profile that has an adjustable depth and an adjustable reveal that gives panels the true appearance of clay tiles. This machine can produce through fastened panels in steel. It is capable of forming two different roof tiles with the same tooling, creating a perfect, scrape-free finish.

...more

roofing machine

Roofing machine is used to manufacture heat-preserving panels. Its products(heat preserving panels) are both widely used in construction area, which have reliable performance, high quality and beautiful appearance.

...more

Roof Wall Panel Roll Forming Machine

We are specialized in manufacture and design rolling form machine and automatic production lines. The machines are mainly used in the following areas: • In building trade : to product C&Z shape purlin, loading bearing plate, wall or roof steel plate, high-grade colorful decorating and protecting steel plates; • In environment line: to make anode plate and cathode plate for dust catcher; • In transport line: to make freeway guardrail plate, vehicle board; • In logistics line: to product goods shelf pillar, holding beam, joist; • In Electrical equipment line: to make cable bridge, box pillar and others thin wall rolling form materials. Such as goods shelf board, kinds of box panels etc. • We also can supply other machine lines such as coiled, uncoiled, check level, end long cutting, across cutting, buttress. Our machines characteristics are high efficiency, high flexibility and low production cost. All of our machines have competitive price and quality. We will try our best to make and supply you the suitable machine for you accordance with your requirements. We can services for you from the begging to the end. Believe you will be satisfied with our best quality equipment and good sevice.

...more

Roof Roll Forming Machine

We are specialized in manufacture and design rolling form machine and automatic production lines. The machines are mainly used in the following areas: • In building trade : to product C&Z shape purlin, loading bearing plate, wall or roof steel plate, high-grade colorful decorating and protecting steel plates; • In environment line: to make anode plate and cathode plate for dust catcher; • In transport line: to make freeway guardrail plate, vehicle board; • In logistics line: to product goods shelf pillar, holding beam, joist; • In Electrical equipment line: to make cable bridge, box pillar and others thin wall rolling form materials. Such as goods shelf board, kinds of box panels etc. • We also can supply other machine lines such as coiled, uncoiled, check level, end long cutting, across cutting, buttress. Our machines characteristics are high efficiency, high flexibility and low production cost. All of our machines have competitive price and quality. We will try our best to make and supply you the suitable machine for you accordance with your requirements. We can services for you from the begging to the end. Believe you will be satisfied with our best quality equipment and good sevice.

...more

Roof Panel Roll Forming Machine

• Coil width:1250mm • Roller stands:18 • steel thickness: 0.4-0.8mm • roller material : 45#stell ,coated with chrome

...more

Roof Forming Machine

Roof forming machine for heat-preserving panel is used to manufacture heat-preserving panels. Its products(heat preserving panels) are both widely used in construction area, which have reliable performance, high quality and beautiful appearance.

...more

Roller Shutter Door Forming Machine

Roller Shutter Door Roll Forming Machine can produce rolling shutter door with good quantity: Introduction of Roller Shutter Door Roll Forming Machine. The line consists of decoiler, sheet guiding equipment, roll forming section, cutter, supporter, hydraulic system, control system. The roller shutter, which made by this machine have neat external appearance, even ripples, high utilization and strong strength. Rolling Shutter Door Forming Machine Equipment Main technical parameter: • Material of Roll Shutter Forming Machine: Galvanized steel sheet • Thickness of raw material: 0.6--1.0mm • Width of raw material: 198mm • Effective width of Roll Shutter Forming Machine: 118mm • Main motor power of Roll Shutter Forming Machine: 4kw • Hydraulic motor power: 2.2kw • Roller stand: 15 groups • Material of cutter: Cr12 • Working speed of Roll Shutter Forming Machine: 10-12m. Min • Total weight of Roll Shutter Forming Machine: About 4MT • Voltage: 380V 3 phase 60 Hz or as per the customers' requirements • Control system: PLC control Roller shutter doors roll forming machine: • Machine's components • Uncoiler and its base. • Guiding equipment. • Roll forming system. • Hydraulic system. • Cutting system. • PLC control system. • Support table. Main technical parameters: • Material: 0.5-07mm color steel or galvanized steel sheet; • Uncoiler's loading capacity: Max. Capacity: 5000Kgs. (can be increased to be 10 tons) • Motor power: 4Kw(depend on final design); • Control system: Mitsubishi PLC&converter. • Cutter material: Cr12 mould steel. Roll Shutter Door Machine.

...more

Remote Control Sliding Shutters

We present a range of Remote Control Sliding Shutters that are perfect for maintaining privacy or protective valuables in a modernized manner. The Remote Control Sliding Shutters are manufactured using special PPGI Steel that adds durability while maintaining a high visual appeal. Suitable for total comfort, the Remote Control Sliding Shutter is ideal for people with disabilities, the elderly and also for large rooms with many windows that require a lot of effort to reach. Manufactured using latest technology, the Remote Control Shutters have motor at the base that controls all the louvers at one time and we can also upgrade any manual shutter to an automatic one with ease. Specialty Radio frequency technologyEnergy and time saving featureAdvanced mechanism to control light and glareSmooth operation even in case of motor failureOptions for mid-operation stopping provided with electric brake and remote Remote Options 1-channel for 1-2 rooms5-channel for the complete house (used to set individual panels, windows, rooms, or an entire section) Suitable For HomesOfficesShopsCollegesHospitals.

...more

Punching Machine

We are offering high quality Punching Machine which is exclusively used to cut, crease and emboss board. We are offering Punching Machine at a reasonable market price. We manufacture them by using high quality raw material taken from trusted sources. We supply Punching Machine to fulfill the different requirements of our clients. Available in customized forms, these products are used for punching all types of consoles and bumper/fender/dashboard & other plastic material. Available with hydro-pneumatic, hydraulic and pneumatic systems, these products also provide CMM reports for quality checks. Our Punching Machines offer the best value for money. All the material used in the fabrication process is procured from the reliable vendors and are of the optimum quality. This helps us to come up with absolute flawless products, which are durable & corrosion resistant. This machine is used to create designs of different patterns into items such as shoes, pocketbooks, leather items or cardboards boxes. Uses an imported lead screw of high precision. The software is developed by us and uses the latest DSP controller chip. It's capableof high speed and is easy to use. This comes with 3 heads each capable of punching 8 holes a second. The heads can rotate into any angle and create patterns in a non – linear fashion. The Punching Unit by adjust the punching unit,the machine can work on various shape of siding board ,with accurate and eren punching effect.

...more

profile making machine

.Suitable to process:Colored Steel plate, galvanized board 2.Width of the plate:1000.1220.1250.mm 3.Rollers:13-16 rows 4.Rolling material: Forging Steel 45# 5.Rolling galvanization thickness:0.05 mmRoll material:variety of steel plate

Voltage : 380V 50Hz 3PH

...more

press break machine

Santkrupa Shutter Roofing Machine have been designed & developed for continuous production & accuracy. The rigid frames are fabricated with tested plates, its interlocked construction with the bed directly supported on the side walls ensures consistent. accuracy & perfect alignment. A high Torque - Low Inertia Friction cone Clutch linked with heavy duty Brake arrangement ensure max. transmission of torque and power. It is designed for easy control of the Ram speed and for frequent starting and stopping. The clutch is readily accessible and adjustable easily. Gun Metal Bushes are provided in all running parts. It is true that most of the time metal is to be formed prior it can be utilized for some particular needs. Nowadays there are lots of solutions you may opt for in order to form a metal but the most commonly opted for is the using of a machine press. It is generally known truth that metal forming press uses some type of force to change the original shape of the metal. The good thing about press break is that angles formed with such press can be pretty accurate. Depending on what type of die is utilized, various bends can be handled at one time. This metal machinery has two frames that are attached to a special table with a ram on the bottom and beam on the top. A press break, also known as a break press or just break, is a machine tool for bending sheet and plate material, most commonly sheet metal. We own the widest range of Press Brake Machine in multi shapes and models that gives you a plenty of option to choose from. Our hydraulic press break machine is well known for its unending durability and ability to work up to max on any given day. Also, our machines are low costing and can be afforded by anyone. That is why we are rated as the chief press break machine suppliers in India. Having a whole steel structure, our press breaks has the features of strong strength and rigidity and stablility. In addition, our press breaks has simple and beautiful outlook to be the best choice for you. For the excellent performance and easy operation, this modern press breaks has earned a wide popularity.

...moreBe first to Rate

Rate ThisOpening Hours