Tape Layering Machine

175,000 - 280,000 Per Set

1 Set (MOQ)

SEQUIN YARN MACHINE

48,000 - 56,000 Per QUANTITY

1 QUANTITY (MOQ)

fancy sequine yarn making machine with heavy duty device and computerized system with adjustable sequince gaping and size.

Best Deals from Textile Machine

plastic cops

Get Price Quote

1000 Piece(s) (MOQ)

Sizes 38mm dia X 42mm diameter 220 & 240mm length Available in 60 and 70 pot Designed for Viscos Rayon Yarn .

Jari Covering Machine

300 - 330 Per p

100 pcs (MOQ)

yarn twisting machine

2,600 - 15,000 Per

336 Spindel one m/c set (MOQ)

Fabric Shiner & Emboss Machine

Get Price Quote

This is Shiner & emboss machine. for shiner machine a shiner roll fitted in machine and for emboss machine paper roll, cotton roll and design roll fitted in machine.

Straight Knife Cloth Cutting Machine

Get Price Quote

We are the main supplier of this product.

WEFT TENSIONER (BALL)

295 - 500 Per Box

20 Box (MOQ)

swastik bharat brand ball available

WaterJet Looms

Get Price Quote

Suitable for Most-Economic production Filament Fabrics : High-Speed operation with speeds upto 800 RPM for most cost-efficient production. High Production of Light-Weight fabrics with Filament warp & weft. High production of Light-Weight technical fabrics. Lowest Operating cost among all technologies. Electronic Let-Off for constant tension control in technical fabrics. Weft Selection of upto 3-Colour for high value added filament fabrics Standard Positive Let-Off for very delicate Warp yarns to avoid Start/Stop marks. Electronic Take-Up for instant pick-change & fast setup time. 2-Pump System for wider widths Shedding options of Cammotion, Dobby & Jacquard. *Compact & Space saving design lowers total investment costs. * Balanced Crank-Shaft for High-Speed Operation. * 2.5 Tons of weight for the loom gives stability. * Positive Zero-Max Let-Off standard. * Electronic Feeder with Length Counter System. * Electronic Dobby & Electronic Jacquard Synchronised with Main Drive. - Sturdy Balanced Frame Structure for Stable Operation at High Speed - Optimised beat-up design for Energy Saving - Options upto 3-Colors for Weft Selection - Batch Motion option available for Technical Fabrics - Electronic Take-Up system for ease of setting. - Available in wide reed widths from 60” to 90”.

Horizontal Single Vessel Dyeing Machines

Get Price Quote

Salient Features • Loading capacity from 100kg to 1000kgs. • M/c can be loaded 50% & above at almost constant liquor ratio. • Automatic coupling system to increase batch capacity due to modular design. • Machine can be installed on a normal plain ground floor without special foundation. • Machine can be installed at mezzanine ceiling level, even at under ground pits. • Elimination of over head cranes for loading and unloading. • Low liquor ratio of 1:5 to 1:7 as per package density. • High flow rate due to axial flow pump design with inbuilt flow direction reversal system. • Perfect dyeing uniformity can be obtained even in large diameter package. Applications • Yarn Packages. • Small Width Fabrics. • Zipper Tapes. • Muffs & Tops. Standard Configuration (applicable To All Dyeing Machines) • All machines are available in semi-automatic & Automatic version. • All Machines are made from corrosion resistant stainless steel grade AISI-316 SS. • Pressure extraction system. • Package outer diameter 190 mm. • Die spring inside diameter 57 mm x 170 mm length. • Package weight depends on type of yarn. • Polyester FDY package weight will be approx. 1.5 kgs at package density 0.4 gms/cm3. • Cotton package weight will be approx. 1 kgs at package density 0.27 gms/cm3 . • Operating temperature 140°c maximum. • Operating pressure 4 kg / cm2 maximum.

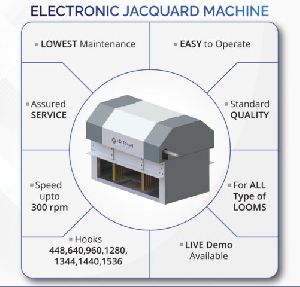

Electronic Jacquard

170,000 - 200,000 Per Piece

2 Piece (MOQ)

Two for One Twisting Machine

2,250 Per Piece

95 MM BAKELITE CORKSIT DRUM

26 Per

We are the main supplier of this product.

woolen weaving looms

Get Price Quote

Jhalar Lace Machine

Get Price Quote

Semi Automatic Hydro Machine

55,000 Per Unit

CONE TO HANK REELING MACHINE

95,000 Per Bag

01 Piece(s) (MOQ)

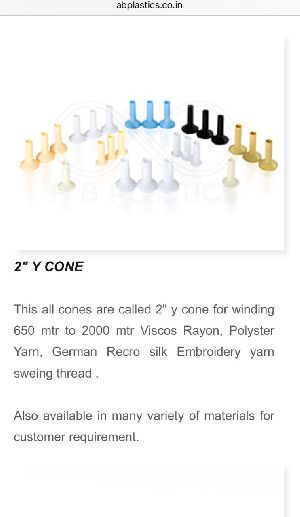

plastic y cones for embroidery thread

Get Price Quote

50000 Piece(s) (MOQ)

We are offering embroidery thread plastic y cones

screen stretching machine

Get Price Quote

This machine enables bolting cloth used in the manufacture of Printing screen, stretched by applying uniform tension in wrap & weft Sides.Motorized controls A Supporting board allows stretching many frames at the same time. No Contact between frame & mesh during stretching process. Simultaneous handling of several screen frames Scope of supply :-A rigidly stayed fabricated base frame work suitably designed for supporting of the screen fabric tensioning arrangement ,which comprises of the following :- A series of pinned plates firmly attached to the stretching machine angular surface section, to retain the screen fabric wrap & weft while being tensioned. Pair of mechanically controlled pinned rollers for stretching / tensioning of screen fabrics. Mechanically controlled table for raising the table & accommodating various sizes of the screen.

cotton tfo machine

600,000 Per Set

1. Double sides, single layer, beautiful aspect, logic structure, easy operation; 2. High quality spindles perform a long-lasting stability under high speed running. 3. At the same time a capsule-type tension regulator is applied, accepting more extensive twisting conditions; 4. Winding tension is regularly on the overfeed roller at will, so applicable to a loose and soft winding for dyeing purpose; 5. Foot pedal barking to remove tangential belt from spindles, constant spindle speed, easy operation, also extending service life both of tangential belt and spindles; 6. Logic end remaining yarn structure makes latter operation job easy and handy; 7. Easily removable waxing device of air loop housing, bringing more adaptability to extensive yarn variety.

Textile machine Parts

Get Price Quote

Textile Weaving Machine

Get Price Quote

The term "Jacquard" is not specific or limited to any particular loom, but rather refers to the added control mechanism that automates the patterning. Our Textile Weaving Machines are preferred worldwide and our highly advanced and technically ordered Jacquard Weaving Machine is ready to perform as per the requirements of various clients. This Textile Weaving Machine gives finest of weaving and it is made in compliance with the industrial standards. These well-tested and most trusted Jacquard Weaving Machines for textile Industry are available in different specifications. We are a reliable Manufacturer, Exporter and Supplier of the Textile Weaving Machine. Product Specifications Of Textile Weaving Machine Model : 600, 400, hooksDimensions (LxWxH) : 950 x 900 x 1450 mmDesign Card Size : 87 x 425 mmOperation Cylinder : DoubleLift : DoubleDrive : Roller chainCenter distance of foot mounting slot on channel : 305 mmClear distance between mounting channels (LxW) : 630 mmChannel Height above ground level : 2250 mm x 3000 mmHeight of the Jacquard Machine : 400hooks -27" & 600hooks - 34", 52" Features Permanent life of Jacquard MachineNo effect of weather change on Jacquard MachineNo wear and tear on Jacquard MachineLubricant & maintenance free of Jacquard MachineSpecial hard aluminum-alloy cylinder with Jacquard MachineSteel frame mounted spring boxFabrics based HYLAM needle board with Jacquard MachineSpecial spring steel hooks and needles in Jacquard MachineDouble cylinder Availability : Standard model and also available in 400, 800, 900 & 1200 Hooks mini and regular height of Variant model of Jacquard Machine Products Manufacturing : Jacquard Machine, Textile weaving jacquard machine, Jacquard Weaving, Jacquard Punch Card, Double Cylinder Jacquard Machine, Jacquard Dress Material & Saree.

High Speed Needle Loom Machine

310,000 - 850,000 Per Piece

1 Piece (MOQ)

Jari Covering Machine

Get Price Quote

10 Piece (MOQ)

Braiding Machine

Get Price Quote

With the assistance of sophisticated packaging system and skilled personnel, we are able to provide damage-free products to the clients as we ensure complete safety during packaging. Ours is a quality-driven organization that is engaged in offering only high-quality products. Thus, we use superior grade raw materials for the fabrication of our entire range.

Flock Cutting Machine

Get Price Quote

Leather Roll Press Machine

350,000 Per Piece

Automatic Weaving Machine

Get Price Quote

Fabric Border Cutting Machine

Get Price Quote

water jet loom machine

Get Price Quote

Electronic let-off with forward & reverse inching synchronisation maintaining uniform warp tension up to beam exhaust. Highly precise mechanical take-up device keeps stable cloth fell assuring higher adaptability for wider range of fabrics. Most convenient and sturdy beam loading unloading and holding mechanism. Well engineered & sophisticate tension monitoring system control.