Tube Condenser

Get Price Quote

1 Piece (MOQ)

Stainless Steel Tube Condenser

80,000 Per Piece

1 Piece (MOQ)

Best Deals from Tube Condenser

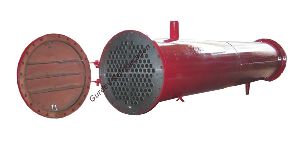

Ammonia Shell, Tube Condensers

Get Price Quote

With the help of our efficient workforce, we are able to offer a comprehensive range of ammonia shell & tube condensers that is designed at par with international quality standards. Our range of shells and tubes are manufactured using premium quality material, components and spares to ensure durability, and are appreciated by the clients due to their robust construction, corrosion resistance and dimensional accuracy. Moreover, we also provide customization as per the specifications detailed by our clients to meet their requirements. features robust constructiondimensional accuracycorrosion resistanthigh performance available in various sizes

Tube Condenser

85,000 - 800,000 Per Piece

1 Piece(s) (MOQ)

Our comprehensive range of products is packed in sturdy, safe, and industrial grade materials that safeguard the contents inside from harm, dampness, dust, movement etc. Besides, the packing has printed product information. With our modern transportation facility, timely deliveries of the placed orders are assured. Features: High-performance Robust construction Easy operations & maintenance

Shell and Tube Condenser

Get Price Quote

1 Piece (MOQ)

Shell and Tube Condenser, Heat Exchanger used for industrial, Herbal Extraction Plants, Pharmaceutical Plants and Chemical Plants. Condenser used in Herbal Extraction Plant, Phyto Extraction Plant for cooling vapors of product.How it worksA shell and tube exchanger consists of a number of tubes mounted inside a cylindrical shell. Vapor runs through the tubes, and water flows over the tubes (through the shell) to transfer heat between the two.These Shell and Tube Condensers are manufactured from high-grade quality material and are easily available at affordable prices. Various Sizes Stainless Steel Options Custom Configurations Highly efficient Easy to install. Leak-Proof. Highly durable. Low maintenance. Operate trouble-free.

Shell and Tube Condenser

5,000,000 - 6,000,000 Per Piece

1 Piece (MOQ)

We are having Vital experience of Designing, simulation, Fabrication, Installation & operation of Shell and Tube Condenser. We are associated with Vincitore Edutechnologies Pune for supply of Heat Exchangers. Following are the benefits to get Heat exchangers designed & Purchased from experts : To analyze process parameters like pressure drop, Heat transfer coefficient for optimization of diameter and Tube length of Heat exchanger for Capital cost saving. To Maximize the Solvent Recovery to get maximum yield. To optimize the capacity of plant to minimize Capital cost. To support operational team during commissioning of equipment.

Tube Condenser

10,000 Per Piece

1 Piece (MOQ)

Shell And Tube Ammonia Condenser

Get Price Quote

wire tube condenser

Get Price Quote

Specifications We are offering the superior quality Refrigerant Wire Tube Condenser. its made using best raw materials which lasts long for years. we are offering these wire tube condenser at very reasonable price to our valuable clients.

Shell and Tube Condenser

Get Price Quote

Shell and Tube Condenser

Get Price Quote

Tube Condenser

900,000 Per

Shell and Tube Condenser

Get Price Quote

The range we offer to the customers is stringently packed and delivered as per the customers' requirement and convenience. We have developed the entire in-house unit wherein we keep our raw material to fulfill variegated requirements of the buyers. Also, we make sure that the material is sourced from the reliable places only. Shell and Tube Condenser has a protective polish on the surface for heat, chemical and rust resistance.

Shell and Tube Condenser

Get Price Quote

We are reliable manufacturer, supplier and exporter of shell and tube condenser. The shell and tube condenser, which we provide, is used for ammonia based refrigeration purposes. Our shell and tube condenser is made from quality components, which ensure its durability. The shell and tube condenser needs only a cleaning tube, in every 6-12 months. why our shell and tube condenser? durable constructioncan be customizedcost-efficientreasonably priced

BITZER K2923 SHELL AND TUBE CONDENSER

600,000 - 650,000 Per pc

Series products:Water-cooled condenser Packaging width:184.0000 CMTGross weight :250.0000 KGM Packaging height:74.0000 CMT Packaging length:68.0000 CMTSeries : Water-cooled condenserType :K2923T-2P Product description Bitzer K2923T water-cooled condenser•Inlet solder connection D54L•Outlet valve D54L•Fixing brackets at the bottom and top•Excluding oil injection kit•Suction valve•Connection for spring safety•Sight glass•Copper piping in heat exchanger, 2 pass application

Tube Condenser

Get Price Quote

From our unit in Pune, Maharashtra we are a distinguished manufacturer and supplier of Tube Condenser. The condensers that we offer are designed and manufactured not only using good quality materials but also by our expert team of engineers to ensure that it is of good quality. These condensers are easy to install and the holes provided at the end allow for the right amount of air for ventilation.

Shell and Tube Condenser

Get Price Quote

We are supported by a reliable team of packaging experts who have immense experience in this domain and capable of catering to the standards and customized packaging requirements. Our entire range of products is produced as per international quality standards. Therefore, they are dependable and worth the price. The baffles are normally plates with a single segmental cut. The cut is usually vertical to allow the condensate to flow along the bottom of the shell to the outlet. Double segmental baffles may be specified to achieve reduced pressure drop. The space between the baffles is determined by considerations such as: The tubes must be supported to avoid tube vibration; Pressure drop depends on vapor velocity, and hence on baffle spacing; The resistance to heat transfer due to the presence of noncondensing gases is inversely proportional to the vapor velocity. High vapor velocities can reduce resistance to heat transfer through the shear effect on the condensate film. Thus, if adequate pressure drop is available, it may be possible to reduce baffle spacing to obtain increased heat transfer rates. The size of the baffle cut is generally chosen such that the vapor velocity in the baffle window is roughly equal to that in the overlap zone between the baffle plates. The number of tube passes is determined by the required coolant velocity. Plain tubes are generally used, though low-finned tubes can be used to obtain increased heat transfer rates when the condensate resistance to heat transfer with plain tubes is significantly greater than that of the coolant. The vapor vent should be situated at the end of the vapor flow path. It is possible to use other TEMA shell types, such as the J-type, to minimize pressure drop. A possible configuration for low pressure drop is the J-shell with double segmental baffles.

Shell and Tube Condenser

Get Price Quote

We make Horizontal Shell and tube ammonia condenser, which are available in different capacity ranging from 5TR to 400 TR.A shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry.Shell and Tube Condensers are having two divisions one is shell and other is Tubes. Here water runs through the tubes, and ammonia vapor flows over the tubes (through the shell) to transfer heat between the two fluids. For this purpose seamless/ERW or Rolled shell are used for shell. And Seamless/ERW tubes are used for Tubes. Different Pass Arrangements are made by providing baffles in the water heads, Like Two, four, six and eight pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler and Helps to limit the tube Length.The ammonia vapors enter the shell and get condensed by rejecting the heat to the circulating water in the tubes there are Baffles directing flow through the shell side so the vapor does not take a short cut through the shell side leaving ineffective capacity.These shell and tube condensers are tested at a hydrostatic pressure of 27 kg/sq. cm gauge (380 psig). We also make shell and tube condensers with SS tubes and SS water heads where the water is saline or very hard so the tubes can be cleaned easily with chemicals.

Ammonia Shell and Tube Condenser

50,000 - 2,000,000 Per Piece

1 no (MOQ)

Ammonia Shell and Tube Condenser - Horizontal shell and tube ammonia condenser, which are available in different capacity ranging from 5TR to 400 TR. A shell and tube condenser (heat exchanger) is the most common type of heat exchanger used in refrigeration industry.

Shell Tube Condenser

Get Price Quote

amt engineering works is a leading and well known manufacturer of shell and tube condenser and complete pharmaceutical plants and pharmaceutical plant machinery manufacturer in india. .