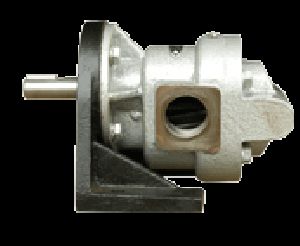

stainless steel gear pump

Anivarya rotary gear pumps manufactures pumps with SS 316 construction. The pumps have SS 316 gears and shafts that are nitrided to give longer life with trouble-free performance. The shaft is supported on self lubricating type Teflon coated DU bushes and the sealing is done with Teflon based Z Pac sealant which gives zero leakage and is easy to maintain. These pumps are available in flange and foot mounting types. They can operate up to maximum pressure of 10 kgcm? and has suction lift of 5 m at rated speed of 1440 RPM. These pumps are highly suitable for pumping and transfer of corrosive chemicals, acids, dyes, resins, pigment, printing Inks and various other liquids up to viscosity of 5000 cst and temperature of 200?C. The pumps are optionally available with built in pressure relief valve. The company also offers simple design cast iron pumps for transfer of non-corrosive liquids, fuel oils, diesel oils, etc, with built-in relief valve facility. Special pumps for OEMs can also be developed as per requirement. Features (Stainless Steel Gear Pump | SS Gear Pumps) PTFE coated bush for smooth performance in dry bearing condition Easy cleaning & maintenance Optional steam jacket Foot & Flange mounting option Application (Stainless Steel Gear Pumps | SS Gear Pumps) Food and Beverages Pharmaceutical Industry Dyeing and printing Houses Chemical industries Cosmetic industries

...more

Rotary Pumps

Lobe pump is used in a variety of industries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIPSIP) characteristics.

...more

rotary lobe pumps

Rotary lobe pump use timing gears to eliminate contact between the rotors, which allows their use on non-lubricating fluids. These pumps offer low shear and gentle handling of the liquid to minimize product degradation. Rotary lobe pumps are useful for pumping and Transfer of all high viscous liquids like syrup paints, drugs, food products, etc. Lobe pump is used in a variety of industries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. Features (Rotary Lobe Pumps) Robust construction Compact size High efficiency Reversible operation Hygienic design Easy maintenance Inter changeable rotor Handling low as well as high viscous liquid Ideal for delicate media & where organic solid suspended particle in liquid Working for Lobe Pump Lobe pump are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection. As the lobes come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the lobes as they rotate. Liquid travels around the interior of the casing in the pockets between the lobes and the casing -- it does not pass between the lobes. Finally, the meshing of the lobes forces liquid through the outlet port under pressure. Lobe pump are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pump than in other PD types. Since the lobes do not make contact, and clearances are not as close as in other PD pumps, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids. Application (Rotary Lobe Pumps) Food industries Chemical industries Pharmaceutical industries Dairy industries Petrochemical industries Sewage plant

...more

Rotary Gear Pump

Rotary lobe pump use timing gears to eliminate contact between the rotors, which allows their use on non-lubricating fluids. These pumps offer low shear and gentle handling of the liquid to minimize product degradation. Rotary lobe pumps are useful for pumping and Transfer of all high viscous liquids like syrup paints, drugs, food products, etc. Lobe pump is used in a variety of industries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIPSIP) characteristics.

...more

pumping system

• Useful for fuel oil loading and unloading• Pumping & Heating system• Force feed lubrication system• Circulation & cooling system• Pumping & filtration system Application (Pumping System) Tanker loading & Unloading Steel plant Cement plant Power plant Petrochemical refineries

...more

Internal Gear Pump

Internal gear pumps are exceptionally versatile. While they are often used on thin liquids such as solvents and fuel oil, they excel at efficiently pumping thick liquids such as asphalt, chocolate, and adhesives. The useful viscosity range of an internal gear pump is from 1cPs to over 1,000,000cP. In addition to their wide viscosity range, the pump has a wide temperature range as well, handling liquids up to 750°F 400°C. This is due to the single point of end clearance (the distance between the ends of the rotor gear teeth and the head of the pump). This clearance is adjustable to accommodate high temperature, maximize efficiency for handling high viscosity liquids, and to accommodate for wear.

...more

helical gear pumps

Useful for pumping and transfer of all viscous liquids, oils and petroleum products ANI Engineers offers Helical Gear Pump, SG Series. It is available in cast iron grade with single helical alloy steel gears and hardened and ground shafts. It has sturdy design and construction to give long and trouble free life and performance. Ultra bronze bush material ensures smoother running than conventional phosphorous bronze. It is available in sizes ?" to 3", capacity range of 20 to 500 LPM and can operate upto a max pressure of 10 kg/cm2 and temperature up to 80?C. Features (Helical Gear Pumps) Single helical gear design. Lower Noise. Compact & Economical Easy maintenance Optional high temperature version up to 200°C Application (Helical Gear Pumps) Vegetable Oil Mills Refineries Ceramic Industries Pumping & transfer or all kind of mineral oils

...more

heavy duty gear pumps

Heavy duty gear pumps (Positive DisplacementRotary Twin gear Pumps) type AERN series pumps are useful for pumping and transfer of all kind of viscous Liquids and petroleum products.Heavy duty gear pumps comes in size From 1/2" to 8" NB(Flanged to ASA 150 classes)Heavy duty gear pump has Capacity of: 0.5 to 200 m3/hr, Press up to 12 Kg./cm2 Heavy duty gear pump has Viscocity up to 1,00,000 -cst, Temperature up to 110° C Technical Specification (Heavy Duty Gear Pumps) Features (AERN SERIES PUMPS) Heavy duty gear pump design for continuous application Herrigebone rotor design eliminate side thrust Modified tooth profile enhances tooth life. Floating gear-design ensures uniform load distribution . Low-leakage path by design improve volumetric efficiency. Shorter bearing span reduces bending effect Optional steam jacket Application (Heavy Duty Gear Pumps) Steel plant Power plant. Petroleum industries Refineries Pumping Station Tanker loading & un-loading

...more

Fuel Injection Gear Pump

Internal gear pumps are exceptionally versatile. While they are often used on thin liquids such as solvents and fuel oil, they excel at efficiently pumping thick liquids such as asphalt, chocolate, and adhesives. The useful viscosity range of an internal gear pump is from 1cPs to over 1,000,000cP. In addition to their wide viscosity range, the pump has a wide temperature range as well, handling liquids up to 750°F 400°C. This is due to the single point of end clearance (the distance between the ends of the rotor gear teeth and the head of the pump). This clearance is adjustable to accommodate high temperature, maximize efficiency for handling high viscosity liquids, and to accommodate for wear.

...more

Flanged Mounted Gear Pumps

Useful for pumping and transfer of all viscous liquids, oils and Petroleum Products. Features (Flanged Mounted Gear Pumps) Compact design. Economical Prices Wide capacity range Optional external ball bearing support to drive shaft Foot & Flange mounting options Application (Flanged Mounted Gear Pumps) Centralize lubrication system Pumping & heating System. Oil filtration and cleaning system Transformer oil purification system Machine tools industries

...more

Internal Gear Pumps

Fuel Pressuring internal gear Pump Internal gear pumps are exceptionally versatile. While they are often used on thin liquids such as solvents and fuel oil, they excel at efficiently pumping thick liquids such as asphalt, chocolate, and adhesives. The useful viscosity range of an internal gear pump is from 1cPs to over 1,000,000cP. In addition to their wide viscosity range, the pump has a wide temperature range as well, handling liquids up to 750°F / 400°C. This is due to the single point of end clearance (the distance between the ends of the rotor gear teeth and the head of the pump). This clearance is adjustable to accommodate high temperature, maximize efficiency for handling high viscosity liquids, and to accommodate for wear. Features (Internal Gear Pumps) Higher suction lift Self priming and capacity to create vacuum up to 600/650 mm hg Flange & Foot mounting option In built relief valve External by-pass arrangement Zero leakage Mechanical Seal Continues duty pump Application (Internal Gear Pumps) Fuel injection in burners, boilers, furnaces Booster application in diesel locomotive Force feed lubrication Heating system.

...more

Heavy duty gear pump

Heavy duty gear pumps (Positive DisplacementRotary Twin gear Pumps) type AERN series pumps are useful for pumping and transfer of all kind of viscous Liquids and petroleum products. Features (AERN SERIES PUMPS) Heavy duty gear pump design for continuous application Herrigebone rotor design eliminate side thrust Modified tooth profile enhances tooth life. Floating gear-design ensures uniform load distribution . Low-leakage path by design improve volumetric efficiency. Shorter bearing span reduces bending effect Optional steam jacket Application (Heavy Duty Gear Pumps) Steel plant Power plant. Petroleum industries Refineries Pumping Station Tanker loading & un-loading

...more

Gear Pump

Rotary Gear Pumps

Be first to Rate

Rate ThisOpening Hours