Z Shaped Bucket Conveyor

Listing Description This conveyor is used for feeding conveying the product material to be packed from floor level to packaging machines hopper. Detailed Description For Snacks, Grains, Granuals, Seeds Feeding. This conveyor is used for feeding conveying the product material to be packed from floor level to packaging machines hopper. This ensures complete protection of product from breakage, from effect of atmosphere, dust, insects etc. This conveyors can be attached to five packaging machines for feeding same material to all machines or otherwise individually to each Machine. Bucket Size : 125 (w) X 400 (b) X 65 (h) mm. Conveyor Height : 2800mm. Material Drop Height : 2500mm. Output : Up to 90 bucketsmin. Bucket material : Made of moulded food grade pp with fine finish to obtain nonstick property. Side chains : Made of SS - 304 with nylon rollers. Other contact parts : SS -304. Material feeding : Through vibratory feeder and controlled by level sensor. Bucket Releiver : Pneumatic bucket releiver for from packing machine, when used for multiple machines or mechanical reliever for individual machine. Motor : 2 Hp, 3 Ph, Geared Motor. It facilitates very easy removal and mounting of the buckets for cleaning. It is an intact system for feeding of material from vibratory feeder to the machine hopper. And hence it protect product from moisture, dust, insects etc.

...more

Take Off Conveyor

Listing Description For Conveying The Packed Pouches From Packaging Machines. Detailed Description For Conveying The Packed Pouches From Packaging Machines. Belt Widths 200mm, 250mm, 300mm (Optional). Belt Type PVC Flat Belt With Slats or Grooved Flat Belt. Conveyor Length 1200mm. Conveying Speed According to packaging machine speed. Speed Control Through VFD Or DC Drive. Motor Wormed Gear Motor.

...more

Smart-Ex Weigh Filler

Listing Description Machine is best for....Extruded Snacks Like Kurkure & Chips, Farsan, Chiwda, Namkeen, Dry Fruits, Grains, Tea, Sugar, Seeds etc. Detailed Description The Machine Is Best for... Extruded Snacks Like Kurkure & Potato Chips, Farsan, Chiwda, Namkeen, Dry - Fruits, Pulses, Grains, Tea, Sugar, Seeds etc. Smart Ex weigh Filler (Available with Single head, 2 Heads, 3 Heads, 4 Heads or 10 H combination Multihead weigher). This model is specially designed for packaging of material having uneven volume & density like potato chips, snacks, Kurkure, dry fruits, grains, pulses, tea, sugar, seeds etc. It is based on load cell electronic weighing technology which measures the material with high precision before being packed into pouches. The machine capacity ranges from 5 g. to 500 g. pouch weight. It has PLC control, making it intelligent & smart. Mechanical functions are pneumatically operated. It is low in maintenance, user friendly with option of single & multiple heads depending upon customer’s requirement. Additional systems available to all our packaging machine Online batch coding device Inert gas flushing systems 3 Side, 4 Side & Center Sealing Batch Cutting device ‘No material’ machine stop Available in GMP Model for Pharmaceutical users. Static charge eliminator for dust free sealing. SpecificationsFilling Capacity (Range) 5gms to 500 gms Filling Speed 600 to 2500 Poucheshr Control PLC Control Mode of Operation Pneumatic Weighing Accuracy +1 gm or weight of 1 piece Packing Material Laminated Films Machine Weight (Approximate) 450 kg Dimension (Approximate) Width 1100 * Length 1500 * Height 2450 Power Requirement 220V, 1Ph, 50Hz OR 420V, 3Ph, 50Hz Machine Range 5 g to 50 g, 10 g to 100g, 20g to 250g, 50 g to 300 g

...more

Smart Ex Tablet Counter

Listing Description The Machine Is Best for.. Tablet, Pharma tablet, Chemical tablets naphthalene balls, Ayurvedic tablets and any other tablets. Detailed Description The Machine Is Best for... Tablet, Pharma tablet, Chemical tablets naphthalene balls, Ayurvedic tablets and any other type of tablets. Smart-Ex with tablet counter is the only solution for packing tablets into pouches on counting basis. This machine is pneumatically operated and PLC controlled. The numbers of tablets can be set through keypad or touch screen. The vibratory base counter filler count the tablets on coarse and fine feeding basis. This high precision tablet counter gives very perfect counting even for small tablets. This machine is suitable for packing range of 1 to 200 tablets. Additional systems Online batch coding device. Inert gas flushing system. 3 side, 4 side, center sealing, guzzeting. Batch cutting device. No tablet machine stop. Available in GMP model for pharmaceutical users. Static change eliminator for dust free sealing. ‘D’ cut or Euro slot or any shape which made to carry the bags easily.

...more

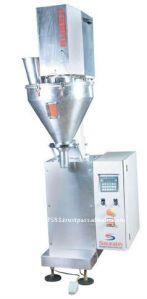

Smart-ex Auger Filler

We are offering smart-ex auger filler. Place of origin maharashtra, india brand name smart ex type packing machine packaging material laminated pouch automatic grade automatic application spices powder, herbal powder, cosmatic powder, pharmaceutical powder condition new packaging type cartons driven type pneumatic built in self fault diagnosis system password protection for setting if no material machine stop minimum maintenance batch cutting device expoxy powder coated structure weight adjustment through touch screen high filling accuracy motorized film trolley alignment systems high density heater for long life & gmp model available for pharmaceutical inert gas flushing systems

...more

Semiautomatic Weigh Filler

Listing Description This Machine Is Best For Extruded Snacks Like Kurkure Potato Chips, Farsan, Namkeen, Dry-fruits, Pulses,Grains, Tea, Sugar,Seeds Detailed Description Application :- Extruded Snacks Like Kurkure Potato Chips, Farsan, Chiwda, Namkeen, Dry-fruits, Pulses, Grains, Tea, Sugar, Seeds, Frozen Cut Vegetables etc. Out put :- 6 to 20 pouchesminhead.(depends on material flowability & gramage.) Head Options : 1 Head, 2 Head, 3 Head, 4 Head, 6 Head. Packaging material :- Any ready pouches Jar, Bags, Containers etc. Power Requirement :- 220V AC 1 Phase, 50 Hz. Compressed Air Required 5 kgfsq.cm. Capacity :- 10gm to 1kg 100gm to 2.5kg 200gm to 5kg 500gm to 10kg 1kg to 25kg 2kg to 50kg

...more

Semiautomatic Cartooning Machine

Listing Description Cartooning Machine Is Best For packing paper box. Detailed Description Maximum Box Size :- 200 mm X 200 mm Box Loading :- Manually After Three Folds Glueing System :- Hot Melt Or Cold Glue System Operation :- Mechanical, Pneumatic, PLC Controlled Conveyor Type :- Clit Chain Type Conveyor Length :- Six Feet Contact Parts :- SS-304 Motor :- 16 Hp Geared Motor Electricity Required :- 420 V, 3 Ph, 50Hz Compressed Air Required :- 6 Bar At Constant Pressure

...more

Semiautomatic Auger Filler

Application: Suitable for Flours, Turmeric powder, Chilli powder, Pesticides powder, Mehandi powder or any type of fine powders etc. Out put 15 fillsmin to 60 fillsmin (subject to model & gramage) Operation: Mechanical Control: Electronically or PLC controlled. Auger screw operating system: CBC driven or servo driven. Packaging material Any ready pouches, jar, containers etc. Power Requirement 220V AC 1 Ph,50 Hz or 420 V AC 3 Ph,50 Hz. (Subject to Models) Capacity 1gm to 100gm 10gm to 500gm 50gm to 1kg 1kg to 5kg 1kg to 10kg

...more

Ribbon Blender

Application : For any type of mixing powder. Available in : MS. & SS. 304, SS. 316, Models. Capacity : 25 kg, 50 kg, 60 kg, 75 kg, 100 kg, 200 kg, 500 kg. Power Requirement 230 V AC 1 Phase (up to 75 kg capacity) 420 V AC 3 phase (from 100 kg & above).

...more

powders like Haldi, Mehandi, Besan, Flour, Talcum Powder, Ground Spices, Herbal Powder

The Machine Is Best for... Free flowing fine powders like Haldi, Mehandi, Besan, Flour, Talcum Powder, Ground Spices, Herbal Powder, Soluble Fertilizer Powder and all kinds of fine powders. Kawach Servo machines are very high speed machines of international standards with all precision. The high end CPU motion control technology gives the highest speed upto 120 pouchesmin. (Depend on product material characteristic & pouch size). All operations are handled by individual servo motor. Kawach servo machines are designed only for large scale manufacturer. These machines runs at high speed with high weight accuracy & sealing intactness. These machines are controlled by motion CPU with touch Screen. These machines have many unique features. Servo Driven Auger Filler is for precise weight accuracy at high speed. Additional systems Online batch coding device. Inert gas flushing system. 3 side, 4 side, center sealing, Guzzeting, block bottom, etc.(optional). Batch cutting device. No material machine stop. No film machine stop. Static change eliminator for dust free sealing. Available in GMP model for pharmaceutical users. ‘D’ cut or euro slot or any shape which made to carry the bags easily. Specifications Filling Capacity (Range) 1 gm to 5 kg Output Speed 35 to 120 pouchesmin (Depends on material characteristics, fill weight and pouch size) Control CPU motion Controlled Operation Servo driven Packaging Material Laminated Film Heating System Hot bar induction heating Reel Core Diameter 70 to 76 mm Roll Holding Pneumatic shaft Maximum Roll weight 60Kg Electricity Required 420V, 3Ph, 50Hz Compressed Air Required 2 cfm at 6 bar pressure Machines Weight (Approximate) 700 Kg to 1500 Kg Dimension (Approximate) 1000(w) X 1200(L) X 2850(h) mm Available in Variety of Models 1gm - 5gm, 1gm - 10gm, 1gm - 19gm, 1gm - 25gm, 5gm - 50gm, 10gm - 50gm, 20gm - 100gm, 50gm - 250gm, 100gm - 500gm, 200gm - 1Kg, 500gm - 2Kg, 1Kg - 5Kg. Note : The designspecification are subject to change without notice on account of contentions improvement in product quality. unique & Special Features High end CPU motion control with touch screen. Individual servo motor for each operation. Computer, printer and internet connectivity. Recipe function on touch panel. Built in self fault diagnosis systems. Three level password protection for settings. Auto web tracking device. Integrated PID temperature controlled for precise temperature control. Very low maintenance(Almost maintenance free). If 'No material or no film' machine stops. Batch cutting device (Optional). All contact parts in SS-304, SS-316L on request Epoxy powder coated Structure. Weight adjustment and speed variation through touch screen. High density heaters for long life & minimum warm up time. Three sensor controlled film unwinding device. Operation and maintenance manual in touch screen

...more

pick fill seal machine

We are offering pick fill seal machine. listing description kawach - roto is the machine on which any type of filler can be attached. Such as auger filler, weigh filler & cup filler. detailed description kawach - roto is the machine to pack any material in any type or shape of products. This machine picks the pouch from the stack of pouches and then pouch holder holds the pouch for batch coding, pouch opening, guzzett zipper and stand up opening, material filling, zipper closing and sealing with nitrogen flushing. the intelligent plc with touch screen controls the machine motions very perfectly. The vaccume system works fantastically to lift the pouch and open the pouch. following are the fillers can be attached with kawach-roto for filling of product with precise weight accuracy. auger filler - for free flowing powders like turmeric powder, mehandi, besan, flours, talcum powder, groud sspices, harbal powder, soluble fertilizer powder and all kind of fine powders etc. weigh filler(linear or multihead) - for extruded snacks like kurkure & potato chips, farsan, chiwda, namkeen, dry - fruits, pulses, grains, tea, sugar, seeds etc. cup filler - for grains, granules & powders like tea, spices, saunf, panmasala, gutkha, supari, etc. piston filler - for pasters, liquids, chutnies, sauce etc. additional systems online batch coding device. nitrogen flushing systems. available in gmp model for pharmaceutical users. 'd' cut or euro slot or any shape which made to carry the bag easily. specificationspouch size range 60mm x 60mm to 300mm x 400mm pouch weight holding capacity max 5 kg pouch types plane, 3 sided, 4 sided, stand up, guzzetted, zipper etc. out put speed 20 to 60 pouches/min maximum stack of pouch 200 pouches control plc controlled operation combination of mechanical & pneumatics pouch material any virgin or laminated film pouch lifting by vaccum cups pouch holding cam operated grippers pouch opening by vaccum cups and taking pouch holder near to each other mechanically pouch stretching system by taking pouch holder far from each other mechanically heating type hot bar induction or impulse type sealing system pneumatically or mechanically operated jaws power requirement 420v, 3ph, 50hz compressed air requirement 6 cfm at 6 bar machine weight (approx) 700 kg t0 1500 kg machine dimension (approx) withoutfilling system 1200(w) x 1500(b) x 1800(h)mm available in variety of models 6 station, 8station, 10 station pouch sizes range 60(w)x60(h) to 100(w)x100(h), 100(w)x100(h) to 150(w)x200(h), 125(w)x125(h) to 200(w)x280(h), 150(w)x150(h) to 250(w)x350(h), 200(w)x200(h) to 300(w)x400(h)

...more

nclined Screw Conveyor (Dump Yard)

Listing Description To convey powders from one station to another station like, from one pulveriser to another, or from pulviser to mixing unit etc. Detailed Description Application: To convey powders from one station to another station like, from one pulveriser to another, or from pulviser to mixing unit, or to pouch packing machines etc. Capacity From 2 kgmin to 200 kgmin. Power Requirement 220 V AC 1 Phase or 420 V AC 3 phase optional variable frequency drive.

...more

Kawach with Cup Filler

We are offering kawach with cup filler. listing description the machine is best for.. solids, granules & powders like tea, spices, sounf, panmasala, gutkha, supari, etc. detailed description the machine is best for... solids, granules & powders like tea, spices, sounf, panmasala, gutkha, supari, etc. kawach series are high tech, high speed machines of international standards, these are designed for mid scale & large scale manufacturer. Kawach can pack pouches from 5 g to 1 kg, these machines runs at high speed with weight accuracy. These machines are plc controlled with touch screen with telescopic cup filling technology for weight measurement. Kawach is known for its fantastic pouch finish. weight can be adjusted in running machine through touch screen. additional systems online batch coding device inert gas flushing systems 3 side, 4 side & center sealing batch cutting device ‘no material’ machine stop available in gmp model for pharmaceutical users static charge eliminator for dust free sealing specificationsfilling capacity 10 g to 10 kg filling speed 1000 to 4000 poucheshr mode of operation pneumatic or servo driven control plc controlled reel core diameter 70 to 76 mm roll holding pneumatic shaft maximum roll weight 50 kg or 500 mm diameter. Material feeding system through suitable z shaped bucket conveyor or acclivitous conveyor with vibratory feeder. Packaging material laminated films weight (approximate) 500 kg dimension (approximate) width 1000 x length 1200 x height 2550 power requirement 220v, 50 hz, 1ph or 420v, 50 hz, 3ph available in variety of models 10 g to 50 g, 20 g to 100 g, 50 g to 250 g, 100 g to 500 g, 200 g to 1 kg.

...more

Kawach Servo with Multihead Combination, Weigh Filler

We offer kawach servo with multihead combination. listing description extruded snacks like kurkure & potato chips, farsan, chiwda, namkeen, dry - fruits, pulses, detailed description the machine is best for.. extruded snacks like kurkure & potato chips, farsan, chiwda, namkeen, dry - fruits, pulses, grains, tea, sugar, seeds, frozen cut vegetable etc. kawach servo machines are very high speed machines of international standards with all precision. The high end cpu motion control technology gives the highest speed up to 100 pouchesmin. (depend on product material characteristics & pouch size). All operations are handled by individual servo motor. Kawach servo machines are designed only for large scale manufacturer. These machines run at high speed with high weight accuracy & sealing intactness. these machines are controlled by motion cpu with touch screen. These machines have many unique features. 14 head, 16 head or 20 head combination multihead gives precise weigh accuracy at high speed. Kawach servo bagger comes with following combination multihead weighing system with or without timing bucket as per customer requirement. 1) japanese(ishida or yamato) 2) chinese additional systems online batch coding device inert gas flushing systems 3 side, 4 side, center sealing, guzzeting, block bottom etc. (optional) batch cutting device no material machine stop no film machine stop static charge eliminator for dust free sealing available in gmp model for pharmaceutical users 'd' cut or euro slot or any shape which made to carry the bags easilyspecifications filling capacity (range) 5 gm - 1 kg output speed 50 to 100 pouchesmin (depends on material characteristics, fill weight and pouch size) control cpu motion controlled operation servo driven packaging material laminated film reel core diameter 70 to 76 mm roll holding pneumatic shaft maximum roll weight 60kg electricity required 420v, 3ph, 50hz compressed air required 2 cfm at 6 bar pressure machines weight (approximate) 700 kg to 1500 kg dimension (approximate) 1000(w) x 1800(l) x 3600(h) available in variety of models 5gm - 100gm, 20gm - 200gm, 5gm - 200gm, 100gm - 500gm, 200gm - 1kg note : the designspecification are subject to change without notice on account of contentions improvement in product quality. special features high end cpu motion control with touch screen. Individual servo motor for each operation. Computer, printer and internet connectivity. Recipe function on touch panel. Built in self fault diagnosis systems. Three level password protection for settings. Auto web tracking device. Integrated pid temperature controlled for precise temperature control. Very low maintenance(almost maintenance free). If 'no material or no film' machine stops. Batch cutting device (optional). All contact parts in ss-304, ss-316l on request epoxy powder coated structure. Weight adjustment and speed variation through touch screen. High density heaters for long life & minimum warm up time. Three sensor controlled film unwinding device. Operation and maintenance manual in touch screen

...more

Kawach Multi Head Combination Weigher

We offer kawach multi head combination weigher. listing description the machine is best for.. extruded snacks like kurkure & potato chips, farsan, chiwda, namkeen, detailed description the machine is best for... extruded snacks like kurkure & potato chips, farsan, chiwda, namkeen, dry - fruits, pulses, grains, tea, sugar, seeds, frozen cut vegetable etc. high speed and precision weighing is the uniqueness of multihead weigh filler. Kawach series is well for its pouch finish and sealing intactness which prevents leakage of inert gas from pouches and gives extended product shelf life. additional systems online batch coding device inert gas flushing systems 3 side, 4 side, center sealing, guzzeting, block bottom etc. (optional) batch cutting device no material machine stop no film machine stop static charge eliminator for dust free sealing available in gmp model for pharmaceutical users 'd' cut or euro slot or any shape which made to carry the bags easily. specificationsfilling capacity (range) 5 gm to 5 kg output speed 20 to 60 pouchesmin (depend on model) packaging material laminated films heating system hot bar induction, controlled through pid control plc controlled mode of operation pneumatic reel core diameter 70 to 76 mm roll holding pneumatic shaft maximum roll weight 50kg electricity required 420v, 3ph, 50hz compressed air required 8 cfm at 6 bar pressure machine weight 1400 kg(approx) machine dimension 1800(w) x 1800(l) x 3350(h) mm weighing head option 8 h, 10 h, 14 h available in variety of models 5gm - 100gm, 20gm - 200gm, 5gm - 200gm, 100gm - 500gm, 200gm - 1kg, 500gm - 2kg, 1kg - 5kg.

...more

Kawach Linear Weigh Filler fully Automatic

We offer kawach linear weigh filler. listing description extruded snacks like kurkure & potato chips, farsan, chiwda, namkeen, dry - fruits, pulses, grains, tea, sugar detailed description the machine is best for.. extruded snacks like kurkure & potato chips, farsan, chiwda, namkeen, dry - fruits, pulses, grains, tea, sugar. kawach series machines are very high speed machines of international standards, these machine are designed for mid scale & large scale manufacturer. Kawach can pack pouches from 5g to 10kg. These machines runs at high speed with weight accuracy. These machine are plc controlled with touch screen. Kawach is known for its fantastic pouch finish. The weigh filling system of kawach is specially designed for packaging of material having uneven volume & density like potato chips, snacks, kurkure, dry fruits, grains, pulses, tea, sugar, seeds, etc. It is load cell based electronic weighing technology which measures the material with high precision before being packed into pouches. It comes in single & multiple heads depending upon customer’s requirement. additional systems online batch coding device inert gas flushing systems 3 side, 4 side, center sealing, guzzeting, block bottom etc. (optional) batch cutting device no material machine stop static charge eliminator for dust free sealing available in gmp model for pharmaceutical users 'd' cut or euro slot or any shape which made to carry the bags easily specificationsfilling capacity 5 g to 10 kg filling speed 1000 to 4000 poucheshr control plc controlled mode of operation pneumatic packaging material laminated films machine weight(approx) 500 kg - 1500 kg dimension(approx) 1000(w) x 1200(b) x 2550(h) mm power required 220v, 1ph, 50hz, or 420v, 3ph, 50hz(stabilised) compressed air required 5 to 8 cfm at 6 bar pressure models available 5gm to 10gm, 10gm to 100gm, 20gm to 250gm, 50gm to 500gm, 500gm to 1000gm, 1kg to 5kg, 2kg to 10kg.

...more

Kawach Auger Filler

Listing Description The Machine Is Best for.. Free flowing fine powders like Turmeric Powder, Mehandi, Flours, Talcum Powder, Ground Spices etc. Detailed Description The Machine Is Best for... Free flowing fine powders like Turmeric Powder, Mehandi, Flours, Talcum Powder, Ground Spices, Herbal Powder and all kinds of fine powders. Kawach(pneumatic and servo driven) series are high tech, high speed & machines of international standards these are designed for mid scale & large scale manufacturer. This machines runs at high speed with high precision weight accuracy. Kawach can pack pouches from 10 g to 10 Kg. Kawach is known for its fantastic pouch finish. The operations of the machine are pneumatic & controlled by intelligent PLC touch screen. High precision auger fillers are for better accuracy at high speed. Kawach servo with servo auger filler gives amazing speed upto 120 pouches per min. Additional systems available to all our packaging machine Online batch coding device Inert gas flushing systems 3 Side, 4 Side & Center Sealing Batch cutting device ‘No material’ machine stop Air removing system Dust collecting system Available in GMP model for pharmaceutical users. Static charge eliminator for dust free sealing. SpecificationsFilling Capacity 10 g to 10 kg Filling Speed 1000 to 5000 poucheshr Control PLC Controlled Mode of Operation Pneumatic or Servo Driven Reel Core Diameter 70 to 76 mm Roll Holding Pneumatic shaft Maximum Roll Weight 50 kg or 500 mm diameter Material Feeding System Through suitable screw conveyor. Packaging Material Laminated Films Weight (Approximate) 500 kg to 1.5 tons Dimension (Approximate) Width 1000 X Length 1200 X Height 2250 Power Requirement 420V, 3Ph, 50 Hz. Compressed Air Requirement 8 CFM with 6 bar pressure Available in Variety of Models 10 g to 50 g, 10 g to 100 g, 50 g to 250 g, 100 g to 500 g, 200 g to 1000 g, 1 kg to 5 kg, 2 kg to 10 kg.

...more

Jumbo Kawach With Servo Auger Filler

Listing Description A Special Machine Designed Incorporating Latest Technology For Speed Packing Of Powders From 5Kg. to 10Kg. Detailed Description A Special Machine Designed Incorporating Latest Technology For Speed Packing Of Powders From 5 to 10Kg. Only Jumbo Kawach with servo auger filler guaranties top quality & performance. A unique material multi sensors system which protect from product wastage. Hi-speed & high precision servo auger filler is well known for its precision of material weighing, is more enhanced in jumbo Kawach model. More attention is given to the aesthetic of pouch, while designing bagger unit. A special pneumatic holder, to hold & control heavy packaging film rolls & pneumatically operated pouch tray & pouch holding system for superior pouch finish is unique in Jumbo Kawach. The pouching speed is amazing between 20-30 pouches per min., which can be synchronized with flour or powder mill. Additional systems Online batch coding device. Inert gas flushing systems. No material machine stop. Available in GMP model for pharmaceutical users. Static charge eliminator for dust free sealing. Speed Upto 30 pouches per minute. Synchronized to mill production. Technology that perfectly seals pouches. Sensors at various locations to minimize product & packaging wastage. 'D' cut or euro slot or any shape which made to carry the bags easily. SpecificationsFilling Capacity(Range) 5 Kg to 10 Kg Output Speed 20-30 pouches per min Control PLC Controlled Mode of Operation Pneumatic or Servo driven Heating System Hot bar Induction or Impulse heating Reel Core Diameter 70 to 76 mm Roll Holding Pneumatic shaft Maximum Roll Weight 300 kg or 500 mm diameter Material Feeding System Through suitable Screw Conveyor. Compressed air required 10 CFM at 8 bar Pressure Packaging Material Laminated films or virgin films Machines Weight (Approximate) 2500 Kg Dimension (Approximate) 1700(W) X 2000(L) X 5000(H) mm Electricity Required 420V, 3Ph, 50 Hz Models Available 5 kg, 10 kg, 5 kg to 10 kg(Combo)

...more

horizontal flow wrap

Listing Description The machine is best for... Biscuits, Candies, Cakes, Bearings, Disposable Syringe, Chikkies, Chocolate Bar, Soaps, Noddles etc Detailed Description The machine is best suitable for... Biscuits, Candies, Cakes, Bearings, Disposable Syringe, Chikkies, Chocolate Bar, Soaps, Noddles, Cartridges etc. This machine is best suited for the item to pack in solid form with exact and similar shape in single or multiple numbers in one pouch. This is highly sophasticated machine with touch panel to make it user friendly. It is very high speed and can give upto 250 pouches/min. This machine has a good product dimensional versatility to adopt more product sizes. It’s very easy to make the changeover of product & product size. Additional systems :- Online batch coding device No product machine stop Available in GMP model for pharmaceutical users Double roll mounting shaft for easy changeover & less downtime

...more

High Speed Pouch Sealing Machine

Listing Description The machine is best for... To seal any type of pouches like L.D., H.D., P.P. Laminated, Bopp etc. Detailed Description Application : To seal any type of pouches like L.D., H.D., P.P. Laminated, Bopp etc. Output : 4.5 mtrmin to 20 mtrmin. Power Requirement : 220 V AC 1 Ph or 420 V AC 3 ph. Logo Engraving Attachment : To engrave your logo, Company Name, Packing date, etc. in sealing area. Nitrogen Flushing Device : To flush nitrogen for packing Namkeens, Wafers, Cookies, Pulses etc. Variable speed drive can be provided.

...more

Acclivitious (Slat Belt) Conveyor

Listing Description The belts used is food grade plastic moulded slat belt with side wall to protect spillage of material.It is smooth and noiseless Detailed Description Slat Belt Conveyor For Grains, Granuals, Namkeen, Chips Conveying. The belts used is food grade plastic moulded slat belt with side wall to protect spillage of material. It is smooth and noiseless. Description Slat Belt Conveyor For Grains, Granuals, Namkeen Conveying. Capacity 30-40 Ltrmin. Drop Height 2400mm. Feeding System Vibratory Stock Feeder. Belt Type Food Grade Plastic Moulded Slat Belt Conveyor With Side Wall. Other Contact Parts SS-304. Belt Width 300mm. Motor 1 Hp, 3Ph, Geared Motor. Belt Material Food Grade PP. Structure MS. Duly Powder Coated With Level Sensor & Controller.

...more

gift products

artificial jewelery

Bracelet

Be first to Rate

Rate This